Plant Design

-

Coal

UK Sets Binding Carbon Cuts; Requires CCS at Coal Plants

The UK has all but doomed new coal-fired capacity by simultaneously setting binding carbon reduction goals and by requiring carbon capture and sequestration (CCS) of carbon emissions from new mid-size coal-fired power plants. Existing plants will also be required to retrofit their plants when CCS technology is demonstrated, now estimated to happen by 2020.

-

Coal

FirstEnergy Retools Coal Plant to Burn Biomass

FirstEnergy has announced plans to repower two coal-fired units at the R.E. Burger plant to burn biomass. Conversion of the two units, expected to be completed by 2012, gets the utility off the hot seat with the EPA for alleged Clean Air Act violations.

-

O&M

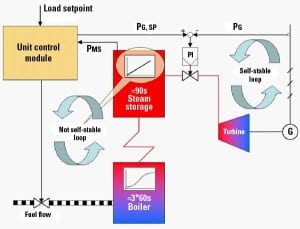

A New Era in Power Plant Control Performance

Recent improvements in the performance of steam power plants have been achieved with advanced computerized controls. These new control schemes not only reduce fuel consumption and make the plant much more responsive, but they also can significantly decrease start-up commissioning time and cost.

-

O&M

Dominion Solves Mt. Storm’s Fuel-Handling Problems with Improved Coal Silo Design

Many coal-fired power stations built before 1980 were designed for handling relatively easy-handling lump coal. If your plant’s bins, bunkers, and silos aren’t up to dealing with today’s range of more variable coal properties, this case study shows one way to minimize coal flow problems.

-

Coal

Designing New Composite Stack Liners

The 200-MW Dallman Unit 4 under construction in Springfield, Ill., is expected to cost approximately 20% less to operate per megawatt-hour than the most efficient of the three existing Dallman units. A composite stack liner is one element enabling that cost savings.

-

Coal

Custom FRP Trench Drains Speed Up FGD System Installation

The flue gas desulfurization process requires the use of aggressive liquids that significantly shorten the life of typical construction materials such as metals and concrete. That makes fiberglass-reinforced plastic (FRP) the material of choice for many components in a typical flue gas desulfurization (FGD) system.

-

Coal

Low-NOx Retrofit for Firing Coal/Petroleum Coke Blends

Replacing existing, older-generation controlled-flow split-flame burners on Unit 1 at the Seminole Generating Station with Foster Wheeler’s new low-NOx burners and overfire air additions reduced NOx emissions. This case study provides all the details and post-installation test results.

-

Coal

Designing Material-Handling Systems for FGD Projects

Reducing NOx, SO2, and other air pollutants continues to be a challenge for the power generation industry. The technologies are well-understood, but the devil is always in the details, especially when a complex treatment system is retrofitted to an existing plant.

The most common method for reducing SO2 from plant emissions is the conventional lime- and limestone-based flue gas desulfurization (FGD) system. Material-handling systems for limestone and gypsum present specific challenges and opportunities that differ from those of coal-handling systems. This article looks at factors to consider before and during the design of a new material-handling system. The choices you make about these many variables will determine the cost and longevity of your system.

-

Coal

From Plan to Plant: The Struggle to Make “Clean Coal” a Reality

In early June, New York Gov. David Paterson proclaimed that his state would commit $6 million to buttress a carbon capture and sequestration (CCS) viability study for the development of a new 50-MW clean coal plant in Jamestown, in western New York. The circulating fluidized-bed (CFB) project, which would use pure oxygen to combust coal and subsequently capture and sequester 90% of emitted carbon dioxide (CO2), would be “the first of its kind in the world” and could potentially enable New York firms to launch exports of the technology worldwide, Paterson promised.

-

Coal

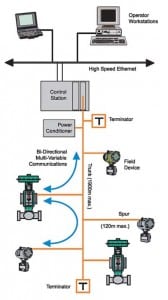

A Fieldbus Primer

Many automation engineers are coming face to face with real fieldbus applications for the first time. Fieldbus (the use of digital communications networks for distributed instrumentation and control) is a wonderful technology with many benefits, but fieldbus installation requires some additional considerations over and above normal 4-20 mA projects. In this article, I present some of those issues and show you how to deal with them.