Plant Design

-

O&M

Site-Specific Factors Are Critical for Compliance with Final 316(b) Existing Facilities Rule

On May 16, 2014, the Environmental Protection Agency (EPA) is scheduled to release its long-delayed final 316(b) rule for existing facilities. The rule—which was supposed to have been issued Apr. 17 after

Tagged in: -

Gas

Recent Innovations from Gas Turbine and HRSG OEMs

There is no hotter market in power generation than gas. According to the Energy Information Administration (EIA), the U.S. is projected to add just under 60 GW of new generating capacity between 2013 and 2017

Tagged in: -

Renewables

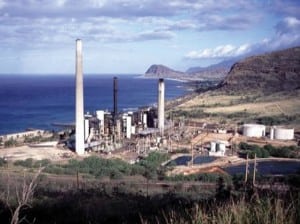

HECO Successfully Cofires Biofuel as No. 6 Oil Substitute

All states were not created equal, particularly when it comes to indigenous reserves of fossil fuels. North Dakota is experiencing a boom in oil production, which has increased almost 10-fold since 2005, and

-

Coal

Fuel-Flexible CFBs Add Flexibility to Resource Plans

The downward trend in solid fuel quality has negatively affected many power generators that rely on imported fuels. For others, this represents a market opportunity. A quick survey of recent installations found that fuel-flexible circulating fluidized bed (CFB) boilers addressed owners’ fuel source concerns by efficiently burning low-quality, high-moisture coals, even when mixed with biomass and […]

-

T&D

Federal Cybersecurity Framework Calls for Increased Vigilance

The energy industry, already familiar with the latest iteration of the North American Electric Reliability Corp. (NERC) Critical Infrastructure Protection (CIP) reliability standards, should take note: Meeting

-

Coal

Drones Promise Faster, Easier Inspection of Boilers, Stacks, Towers, and More

Mention the word “drone,” and most people will have a mental picture of what a drone is and does. They likely will think first of military drones carrying missiles and other weapons that could malfunction

Tagged in: -

Legal & Regulatory

GE Executive Markhoff Talks About the Water/Energy Nexus

Source: POWER During IHS CERAWeek in Houston in early March, POWER Editor Gail Reitenbach sat down with Heiner Markhoff, president and CEO of GE Power & Water’s Water & Process Technologies, to ask him about several issues of concern to power plants. Though the “water/energy nexus” theme has gained prominence recently, Heiner Markhoff’s comments underscored […]

-

O&M

Upgraded Control Room Consoles Improve Ergonomics

Great River Energy (GRE) is a not-for-profit electric cooperative that generates and transmits power for 28 member cooperatives throughout southern, central, and northern Minnesota and northwestern Wisconsin

-

Coal

Establishing Proper Pressure Drop for Feedwater Flow Control Valves

In power plants with drum-type boilers and constant-speed main boiler feed pumps, the feedwater control valve (also referred to as the drum level control valve) provides the means for controlling flow to the

Tagged in: -

Coal

Remote Monitoring and Diagnostics Within a Smart Integrated Infrastructure

It seems as if each week brings further bad news for coal power plants. Recently, Consumer’s Energy sought relief to close three power plants, South Carolina Electric & Gas announced it would cease

Tagged in: