O&M

-

O&M

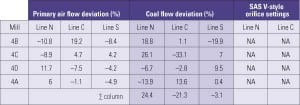

Balanced Pipe Fuel Flow Is Not Enough for Uniform Combustion

Conventional wisdom tells us that the key to good boiler combustion requires carefully balancing the fuel-air ratios across all the coal pipes. Recent tests show that the uniformity of the burner-to-burner stoichiometries—not balanced pipe-to-pipe fuel flow distributions—dictates combustion uniformity.

-

O&M

Dominion Solves Mt. Storm’s Fuel-Handling Problems with Improved Coal Silo Design

Many coal-fired power stations built before 1980 were designed for handling relatively easy-handling lump coal. If your plant’s bins, bunkers, and silos aren’t up to dealing with today’s range of more variable coal properties, this case study shows one way to minimize coal flow problems.

-

O&M

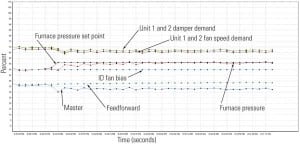

Boiler-Tuning Basics, Part I

Tuning power plant controls takes nerves of steel and an intimate knowledge of plant systems gained only by experience. Tuning controls also requires equal parts art and science, which probably is why there are so few tuning experts in the power industry. In Part I of a two-part series, we explore a mix of the theoretical and practical aspects of tuning boiler controls.

-

O&M

"Blueprint" Your Pulverizer for Improved Performance

Pulverizer throughput is determined by the coal fineness desired for a given coal. However, compromising on coal fineness when your pulverizer isn’t up to snuff can increase NO x and cause many furnace problems. Your least costly option for increasing pulverizer capacity is to pay careful attention to key dimensions and critical tolerances during your next overhaul.

-

O&M

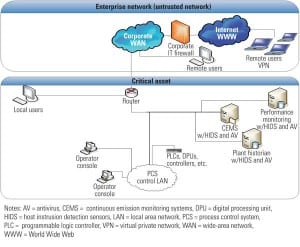

Helping Power Plant Control Systems Achieve NERC CIP Compliance

This guide offers suggestions from a control system engineering perspective for protecting power-generating units that are determined to be critical cyber assets

-

O&M

Best Management Practices for Coal Ash Ponds

The unfortunate coal ash spill at the Tennessee Valley Authority’s (TVA’s) Kingston Fossil Plant that occurred on December 22 has heightened national awareness of the problems associated with utilities’ coal ash surface impoundments if they are not properly maintained.

-

O&M

Reduce Costs with Wireless Instrumentation

New wireless technologies for power plant instrumentation offer significant cost savings when compared to traditional wired networks. The value of this cost savings is especially relevant in the highly competitive power industry, where aging facilities are common and upgrades are an expensive necessity. Modern wireless networks offer a reliable upgrade path that even provides some unexpected benefits when compared to traditional copper networks.

-

O&M

FERC Focuses on Internal Compliance Programs

By now, most electric industry participants are aware of the mandatory reliability standards required by the Energy Policy Act of 2005 and managed by the North American Electric Reliability Corp. (NERC). Bulk-power system users, owners, and operators (known as NERC registered entities) are responsible for complying with the set of standards that are applicable to their operations in their specific region. Compliance is monitored by the NERC regions (Texas Regional Entity, Western Electric Coordinating Council, Reliability First Corp., Midwest Reliability Organization, SERC Reliability Corp., Florida Reliability Coordinating Council, Northeast Power Coordinating Council, and Southwest Power Pool) through spot checks, self-certifications, audits, and investigations.

-

O&M

Preventing Boiler Code Violations Creates a Safer Work Environment

Nearly 10% of boilers and pressure vessels inspected in the second quarter of 2008 were slapped with violations, which means that the violations put workers and equipment in danger, according to a quarterly report released by the National Board of Boiler and Pressure Vessel Inspectors.

-

O&M

Converting a Pump to Use Mechanical Seals

Wear and leakage are common maintenance problems that result in pump discharge pressure dropping below optimum levels and reduced pump efficiency. Converting pumps to mechanical seals eliminates fretting or grooving of the shaft and provides for easier pump maintenance. By converting to mechanical seals, a plant also avoids incurring expenses associated with the replacement of sleeves and shafts.