O&M

-

O&M

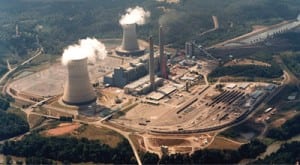

Variable-Frequency Drives Upgrade Reactor Circulating Pumps

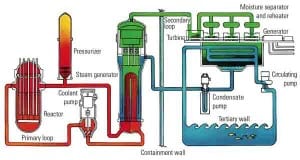

A recent trend in nuclear power plant upgrades has been the replacement of the motor-generator (MG) sets that drive the reactor circulating pumps with variable-frequency drives (VFD). Siemens’ first application of VFDs in this industry began in 2000 with an installation of six VFDs at the Browns Ferry Nuclear Plant. The use of the VFD continues to expand, and upgrades were recently completed at several U.S. plants, including the Hatch Nuclear Plant in Georgia.

-

O&M

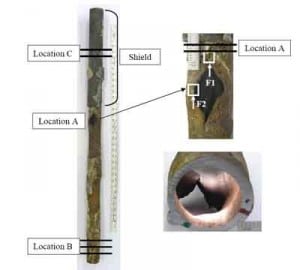

The Role of Fireside Corrosion on Boiler Tube Failures, Part II

One of the primary challenges of reliably burning coal is managing the corrosion experienced by the furnace heat transfer surfaces. Fireside corrosion remains a leading cause of failure in superheater and reheater tubes. In Part I, we examined three case studies of different failure modes experienced by tubes located throughout the furnace. In Part II, we conclude with two additional boiler tube failure case studies.

-

O&M

Improving SCR Performance on Simple-Cycle Combustion Turbines

Austin Energy replaced the selective catalytic reduction (SCR) catalyst twice over five years for its four peaker turbines. The duct modifications and injection grid redesign, combined with new catalyst, are producing high NOx reduction and low ammonia slip, and the catalyst is now expected to last at least five years.

-

O&M

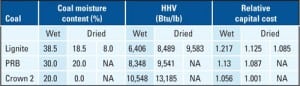

Power 101: Flue Gas Heat Recovery in Power Plants, Part II

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we continue our three-part series on the essentials of recovering heat from flue gas to dry and process coal, with the goal of improving overall plant operating efficiency.

-

O&M

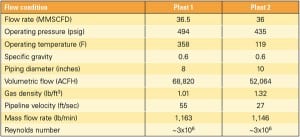

Real-Time Monitoring of Natural Gas Fuel Cleanliness

Gas turbines require clean gas to operate efficiently. Particulate contamination fouls fuel nozzles, causes increases in flue stack emissions, and occasionally causes unplanned plant outages. Now a new real-time natural gas cleanliness monitoring and web-based alarm system is providing valuable protection for natural gas–fired power plants. The adaptation of laser light–scattering technology for the purpose of contaminant measurement in high-pressure gaseous pipelines provides a method of monitoring liquid and solid contamination levels.

-

O&M

Competitive Maintenance Strategies, Part III

This third and final installment addresses three more areas where an investment in good maintenance practices pays operating availability dividends.

-

O&M

Natural Gas Piping: It’s Time for Better Risk Control

At least 10 workers have died from natural gas piping explosions in the past 12 months. The most recent disaster, which occurred during gas system purging at the Kleen Energy Systems plant, claimed five lives and injured 27 workers. It’s time the industry understood the unique design and safety requirements for working with and purging natural gas piping.

-

O&M

Forensic Engineering: A Valuable Tool in Incident Investigations

Much like the crime scene investigators on the CSI TV shows, power plant investigation teams are increasingly employing forensic engineering methods to gather evidence and determine the causes of malfunctions of equipment, materials, or products that result in personal injuries or property damage. Case studies show how different investigation teams used their forensic engineering expertise to examine a dust collector explosion, a coal terminal fire, and the failure of a forced draft fan.

-

O&M

A Burning Concern: Combustible Dust

If not properly controlled, coal and coal dust can cause fires, explosions, and implosions at power plants. Strategies for promoting safer management of these combustibles include actions such as training personnel exposed to the hazards of coal and coal dust about safe handling methods.

-

O&M

Laser Hole-Shaping Improves Combustion Turbine Efficiency

Laser shaping technology has evolved from a two-step process into a single process that drills and shapes holes through a TBC, bond coat, and airfoil base metal to create a finished product.