Gas

-

Gas

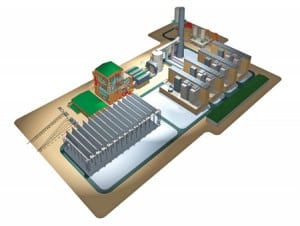

Kårstø Power Plant, Stavanger, Norway

Power supplies are looking brighter these days in the Land of the Midnight Sun now that the Kårstø combined-cycle power plant has begun commercial operation. Kårstø is Norway’s first commercial onshore gas-fired combined-cycle plant. Combining Scandinavian savvy with German engineering, this 420-MW plant showcases maximum efficiency coupled with minimal emissions.

-

Gas

Port Washington Generating Station, Phase 2, Port Washington, Wisconsin

We Energies’ Port Washington Generating Station Phase 2 is recognized as a 2008 POWER Top Plant for its design innovation and strong teamwork among the owner, contractor, and craft personnel that ensured project completion on time, on budget, and with a stellar safety record. While staying true to its historical roots, the plant will remain a good neighbor and a reliable provider of intermediate-load power to the region for many years to come.

-

Coal

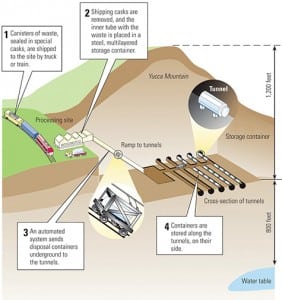

Global Monitor (July 2008)

Yucca Mountain plan sent to NRC/ CPV cells get cooling chips from IBM/ StatoilHydro to pilot test first offshore floating wind turbine/ U.S. rivers next massive power source?/ Siemens delivers 500-MW gasifiers/ Algae: A green solution/ POWER digest

-

Coal

Woods and power company CEOs agree: “The state of the industry is cautious”

It is rare indeed to witness, at an otherwise staid industry forum, the public rebuke of the country’s most prominent supplier to the electric power industry. But at the Keynote session and Power Industry CEO Roundtable of the 2008 ELECTRIC POWER Conference & Exhibition in Baltimore this May, Milton Lee, general manager and CEO of […]

-

Coal

Global Monitor (June 2008)

Artificial photosynthesis for solar power? / Poultry litter to fuel 55-MW N.C. plan / First fuel cell-powered plane takes flight / First HTS transmission cable energized / PTC powers wind power industry / Renewing Greensburg / GAO deems coal-to-gas switch impractical / Assessing the Congo River’s power potential / POWER digest / Corrections

-

Coal

Global Monitor (April 2008)

Tenaska proposes first new coal-fired plant with carbon capture/ Concerns raised over growth of China’s CO2 emissions/ Sandia, Stirling Energy Systems set new world record/ Indonesia orders first Wärtsilä Gas Cubes/ First wind turbines on Galapagos Islands cut oil imports/ Harnessing waste heat for electricity/ POWER digest/ Correction

-

Gas

Castejon 2: Ready to reign in Spain

The new, 424-MW Castejon 2 combined-cycle plant designed and built by Alstom was recently given its provisional acceptance certificate. Alstom used its “Plant Integrator” approach to fast-track delivery of a plant just like Castejon 1, which averaged 98% availability during its first three years of operation. That kind of performance is crucial to generators operating in the Spanish merchant power market—or any market.

-

Coal

Global Monitor (March 2008)

DOE scraps FutureGen / U.S. nuclear plants have record year / Westinghouse wins TVA contract / UniStar Nuclear to file for COL / AEP ranks second in U.S. construction / China moving to the driver’s seat / New solar cycle poses risks / Dutch favor power from natural gas / POWER digest / Corrections

-

Gas

How to make a power plant a welcome neighbor

Developing power projects has become less a technical challenge and more an exercise in developing good relationships among all the stakeholders. If a community understands the need for a new plant and is involved in its development process, the odds of a successful project increase.