Coal

-

O&M

A Burning Concern: Combustible Dust

If not properly controlled, coal and coal dust can cause fires, explosions, and implosions at power plants. Strategies for promoting safer management of these combustibles include actions such as training personnel exposed to the hazards of coal and coal dust about safe handling methods.

-

Coal

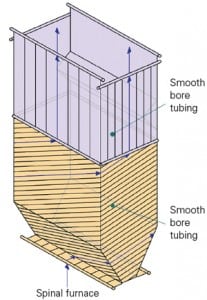

First Posiflow Benson Boiler Completes Seven Years of Service

Seven years have passed since the world’s first low mass flux vertical tube once-through furnace was put into operation by Doosan Babcock at the Yaomeng Thermal Power Plant Unit 1 in China. That boiler replaced a boiler of another design that had become unreliable. The operating experience with the Posiflow design has been so positive that the owner has since ordered and commissioned a replacement for Unit 2’s boiler. Here’s what makes this furnace design unique.

-

Coal

Adding Desalination to Solar Hybrid and Fossil Plants

Shrinking water supplies will unquestionably constrain the development of future power plants. A hybrid system consisting of concentrated solar thermal power and desalination to produce water for a plant, integrated with a combined cycle or conventional steam plant, may be the simple solution.

-

Coal

New York Proposes Costly Retooling of Power Plant Cooling

In a move that could cost the state’s electricity generators an estimated $8.5 billion, New York regulators [have] issued a draft policy that would require the installment of closed-loop cooling systems at two dozen large power plants in the state, including oil, coal, nuclear and natural gas generators, to reduce fish kills and other harmful effects to wildlife in the water bodies that supply the plants’ cooling water.

-

O&M

The Unique Challenge of Controlling Biomass-Fired Boilers

Biomass has many advantages as a fuel for boilers: It’s inexpensive, readily available in many regions, CO2 neutral, and its use warrants government subsidies. The fuel also presents unique concerns to the designers, owners, and operators of biomass plants, especially in the design of the control system.

-

Coal

OPG Charts Move from Coal to Biomass

In response to Ontario’s provincial regulatory mandates to phase out the use of coal by the end of 2014, Ontario Power Generation (OPG) is exploring its capability to employ biomass feedstocks to displace coal in some units within the OPG thermal fleet. The primary fuels employed during the respective trials at its Nanticoke and Atikokan Generating Stations have been agricultural by-products and commercial grade wood pellets. The Canadian utility has learned valuable lessons about fuel supply and logistics, and the technical challenges of safely handling and firing high levels of biomass.

-

Coal

From GHG to Useful Materials

Could the transformation of carbon dioxide (CO2) into carbonates and oxides solve the problem of greenhouse gas emissions (GHG) from fossil-fired power plants? Some companies are betting that such processes could make everyone happy and even create new profits. Buzz has been growing about this approach, though the concept has been around for many years.

-

O&M

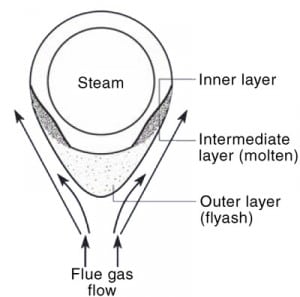

The Role of Fireside Corrosion on Boiler Tube Failures, Part I

One of the primary challenges of reliably burning coal is managing the corrosion experienced by the furnace heat transfer surfaces. Fireside corrosion remains a leading cause of failure in superheater and reheater tubes. Three case studies examine the different failure modes experienced by tubes located throughout the furnace.

-

O&M

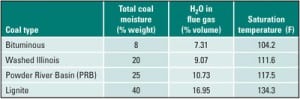

Power 101: Flue Gas Heat Recovery in Power Plants, Part I

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we begin a series of Power 101 tutorials that present these fundamentals in a clear and concise way. First up are the essentials of recovering heat from flue gas.

-

Coal

New Coal Ash Rules May Focus on Conversion to Dry Storage

While the Environmental Protection Agency appears to have initially proposed to regulate power plant coal ash as hazardous waste, there are indications the Obama administration is preparing new federal rules that will at a minimum require utilities to convert coal ash impoundments from wet to dry storage to prevent leaks—a change that would cost tens of millions of dollars but also potentially increase regulated utilities’ rate base and earnings, a Wall Street firm says.