Coal

-

Coal

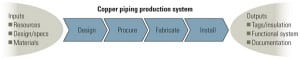

Lean Construction Principles Eliminate Waste

Eliminate waste in coal, gas, or nuclear power plant construction through a holistic application of lean principles.

-

Coal

Canada to Shutter Older Coal Plants

While the U.S. awaits congressional action on a cap-and-trade program that could possibly be limited to just the utility sector, Canada is moving, starting in 2011, to phase out older coal power plants and replace them with natural gas–fired plants. The announcement, made this June by Environment Minister Jim Prentice prior to the G8 and G20 summits, could have serious implications for coal-fired generators in the country.

-

Coal

Breathing Added Life into Failing Heat Exchangers

When heat exchanger tubes—sometimes numbering a thousand or more per unit—begin to crack or wear, the effects can lead to a cascade of subsequent failures in adjacent tubes. If too many tubes are plugged, heat exchanger effectiveness is compromised, and power generation may be curtailed. If conventional mechanical plugs are used, they can break loose, leak, and fail. At that point, the replacement of a very costly heat exchanger is imminent.

-

Coal

Protect Your Stack Linings from Corrosion

Stacks at power generating stations may be low maintenance, but they are not no maintenance. The cost of preventing corrosion may be as little as $10,000, but the cost of repair or replacement could be many times that or even put your plant out of commission until the stack problem is corrected.

-

Coal

Luminant’s Oak Grove Power Plant Earns POWER’s Highest Honor

Luminant used remnants of the ill-fated Twin Oaks and Forest Grove plants (which were mothballed more than 30 years ago) to build the new two-unit 1,600-MW Oak Grove Plant. Though outfitted with equipment from those old plants, Oak Grove also sports an array of modern air quality control equipment and is the nation’s first 100% lignite-fired plant to adopt selective catalytic reduction for NOx control and activated carbon sorbent injection technology to remove mercury. For melding two different steam generators into a single project, adopting a unique and efficient “push-pull” fuel delivery system, assembling a tightly integrated team that completed the project on time and within budget, and for completing what was started almost four decades ago, Oak Grove Power Plant is awarded POWER magazine’s 2010 Plant of the Year award.

-

Coal

Cleco’s Madison Unit 3 Uses CFB Technology to Burn Petcoke and Balance the Fleet’s Fuel Portfolio

With commercial operation of Madison Unit 3, Cleco Power now claims bragging rights for owning the largest 100% petroleum coke–fired circulating fluidized bed power plant in North America. For using readily available fuel in an environmentally attractive manner, adopting fuel-flexible combustion technology, balancing the utility’s generation portfolio, and adopting an innovative fuel-handling system design, Madison Unit 3 is the winner of POWER’s 2010 Marmaduke Award for excellence in operation and maintenance. The award is named for Marmaduke Surfaceblow, the fictional marine engineer and plant troubleshooter par excellence.

-

O&M

Real-Time Monitoring System Measures Air In-Leakage

The amount of air leaking into the boiler envelope is difficult to estimate. Traditional methods of measuring oxygen at the furnace exit and economizer exit do not account for all types of air leakage. By using molar calculations and total airflow measurement, a good approximation of the total air in-leakage rates of a boiler can be quickly determined using station instruments.

-

Coal

Advanced SCR Catalysts Tune Oxidized Mercury Removal

Catalysts used in selective catalytic reduction (SCR) systems in utility boilers provide high NOx removal efficiencies that routinely exceed 90%. A major co-benefit of applying SCR to coal-fired power plants is that the SCR catalyst also oxidizes the vapor phase mercury from an elemental form to a soluble ionic form, which can be readily captured in a downstream flue gas desulfurization process. Mitsubishi Heavy Industries and Cormetech have developed an advanced SCR catalyst technology with high mercury oxidation activity capable of achieving 95% oxidized mercury over a wide range of operating conditions.

-

O&M

Work Process Optimization: Meeting the Challenge of Change

The competitive push for more efficient power generation prompted the management of East Kentucky Power Cooperative’s Spurlock Station to provide training and to implement standardized work processes in order to achieve higher productivity. To that end, Spurlock’s management collaborated with salaried and hourly personnel to design and implement work process optimization. Two years later, their proactive, operations-driven culture is promoting continuous improvement at this facility.

-

Coal

Drax Offers Model for Cofiring Biomass

When it is completed, later this summer, the UK’s Drax Power Station biomass facility will become the largest dedicated cofiring project of its kind in the world. As U.S. coal-fired generators come under increasing pressure to cut emissions and take advantage of incentives to promote power generation from renewables, Drax offers an example of what is possible.