Coal

-

O&M

TECO’s San José Plant Models Safe and Sustainable Practices

In operation since 2000, TECO Energy Inc.’s 132-MW San José Power Station was the first coal-fired power plant built in Central America and is still the largest one. Used as a baseload plant, the facility successfully combines high availability with a business model that promotes sustainable environmental practices and a safe workplace.

-

Coal

Canada’s “Clean” Image Extends to Clean Power

Canada’s extensive natural resources are the driver of its powerful economy, and energy is Canada’s single most important export. Yet policy makers across the nation are currently dealing with the consequences of a generation of under-investment in the electricity system and deciding what the new grid and supply mix should look like. Several provinces are competing to lead the charge in renewable energy and grid intelligence. Policy makers hope that such efforts will not only provide for Canada’s electricity needs but also create the green economy jobs that will drive the nation’s next generation of economic development.

-

Coal

Canada’s Provincial Power Strategies

In Canada, as in the U.S., where you live determines the type of generation technology that provides your power. Here’s how the four most energy-intensive provinces in Canada are responding to the challenge of providing reliable and cheap power in a sustainable way.

-

Coal

Reaching Retirement

A recent Washington Post article attacks coal as a fuel with a dim future. The author points to the large number of plant retirements as evidence of its impending demise. Checking the actual data reveals a much different story.

-

O&M

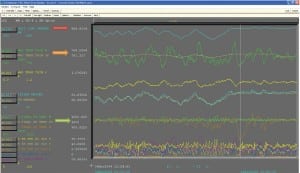

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

Coal

Designing Fuel Systems for Large Biomass Plants

Compared with other solid fuel–fired plants, the systems and components required for handling and processing biomass appear quite familiar, but important fuel differences must be considered. A successful biomass plant design must provide flexibility for handling the expected wide range of biomass fuel properties and characteristics.

-

O&M

Power 101: Improving the Performance of Boiler Auxiliaries, Part II

Efficient boiler operation requires boiler auxiliary equipment to operate in harmony. The air preheater, for example, though it has few moving parts, is vital to maintaining efficient boiler performance. In this second installment of our Power 101 series, we examine performance degradation caused by corrosion and fouling of the air preheater that results from the combustion of coal plus the effects of ammonia and sodium bisulfite injection for SO3 mitigation.

-

Commentary

Pre-Combustion Technologies: A Key Environmental Compliance Tool

Arizona Public Service’s (APS) plan to close three older coal-fueled units at the Four Corners Power Plant in New Mexico and buy out Southern California Edison’s 48% share of the two remaining units is a creative means of surviving the U.S. Environmental Protection Agency’s (EPA) committed action against coal-fueled generation.

-

O&M

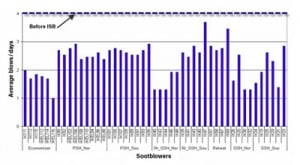

Clinker Minimization at San Miguel Electric Co-Op

San Miguel Electric Cooperative selected and installed an automatic sootblowing system for its Unit 1 to minimize clinkers in the boiler that caused semi-annual unscheduled outages. New boiler surface-cleaning equipment and intelligent cleaning software eliminated these expensive outages.

-

Coal

Duke, Progress Energy Merging into Biggest U.S. Power Utility

Duke Energy and Progress Energy announced January 10 that they are combining to create the nation’s biggest electric utility. The $13.7 billion deal is likely to draw tough scrutiny from federal and state regulators—and some protests from big power buyers—given the companies’ overwhelming market dominance in North Carolina and more modest operational overlap in South Carolina.