-

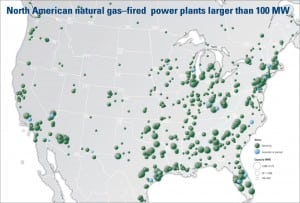

Gas

GTAA Cogeneration Complex, Mississauga, Ontario, Canada

When a blackout shuts down a factory, the impact isn’t apparent to the public. But lose power at an international airport, and thousands of angry travelers and the people waiting for them won’t be interested in excuses. The Greater Toronto Airports Authority learned that lesson in August 2003. Ten months later, it began building a 117-MW cogeneration plant that is now capable of supplying all of its energy needs—not just electricity, but space heating and chilled water as well.

-

Gas

Port Arthur II Integrated Hydrogen/Cogeneration Facility, Port Arthur, Texas

The rationale for a typical cogeneration plant is clear: Supply some power, and maybe some steam, to an industrial host and save energy dollars on both sides of the fence. But integrating a cogen plant that also produces hydrogen with a major refinery that operates 24/7 is a job best left to a company with diverse and proven technology skills. The Air Products Port Arthur II project proves that such a job can be done right. Accordingly, it is one of POWER’s natural gas–fired Top Plants of 2007.

-

Gas

Port Westward Generating Plant, Clatskanie, Oregon

Since going commercial this June, Port Westward Generating Plant has taken its rightful place as one of America’s most efficient power stations. It is now helping to satisfy Portland General Electric’s summer demand reliably and cost-effectively. What differentiates Port Westward is its pioneering use in the U.S. of Mitsubishi Heavy Industries’ G1 class combined-cycle combustion turbine.

-

Gas

Tenaska Virginia Generating Station, Scottsville, Virginia

Not every facility that POWER singles out as a Top Plant has a unique design. Some, like this one, may be recognized for an excellent operations record and being a good corporate citizen. At Tenaska Virginia Generating Station, a formal program to make O&M personnel aware of best industry practices—and apply them on the job—has shortened the plant’s start-up time and elevated its availability, making it much more dispatchable and profitable.

-

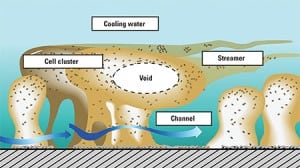

Water

Biofouling control options for cooling systems

The infrequent or improper introduction of biocides into a plant cooling system may make fouling within it worse, by creating thick biofilms that can foster corrosion, reduce heat transfer, and increase water pumps’ operating costs. At the other end of the spectrum, overuse of biocides can waste expensive chemicals. Optimizing the quantity, frequency, and type of dosage can improve both the health of a cooling system and its plant’s bottom line.

-

Instrumentation & Controls

Integrated software platform eludes many owner/operators

Ongoing research into experience with plant- and fleet-level software reveals that these applications work side by side but do not necessarily function as an integrated “knowledge management” system. On the supplier side, the industry continues to be fragmented, with individual programs governing a narrow part of the overall plant.

-

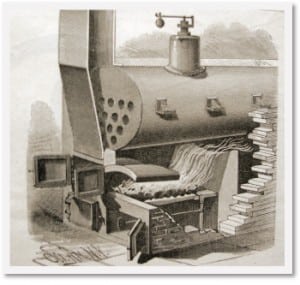

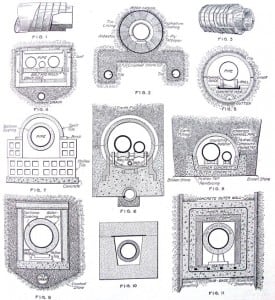

News

This month in POWER . . .

September 1886 Four years after this magazine was launched, the editors reviewed the latest improvements to industrial boilers, beginning with the Backus furnace (Figure 1). 1. The Backus furnace. “This furnace is provided with a brick arch placed just back of the fire-doors, that is intended to deflect the currents of air that are admitted […]

-

Commentary

It’s time to rebalance America’s electricity strategy

Not long ago, most utility investors considered California’s electricity policies too iconoclastic to support. Driven by far-left environmentalists and overzealous regulators, those policies have made it nearly impossible to build new power plants in the state, despite the urgent need for them. Now, however, with growing proof that global warming is real and with Americans […]

-

Coal

The Coal Pile: Steam Blast Rocks Big Apple

This July, an underground steam pipe near Manhattan’s Grand Central Terminal ruptured and spewed a scalding brown geyser of steam and debris higher than the nearby 77-story Chrysler Building. The blast, which injured 30 people, created a 40-foot crater at street level that swallowed a tow truck. A similar explosion in 1989 killed three people. […]

Search