-

Coal

Global Monitor (October 2007)

Siemens ships first blade from U.S. plant; GE’s frames hit 1,000; Battery problems hit hybrid EV programs; Solar thermal rebounds in California;Peabody’s Illinois coal plant gets green light;EPA could sink 278-MW CFB unit; Longest-serving NRC commissioner dies at 58; POWER digest; Readers talk back; corrections

-

O&M

Focus on O&M (October 2007)

Why bypass desuperheaters fail; DSSP, CAD, and fast casting salvage nearly totaled pump; Seals of approval; Making gas turbine plants quieter

-

Commentary

What is resource adequacy?

Under its Resource Adequacy (RA) program, the California Public Utilities Commission (CPUC) requires load-serving entities—both independently owned utilities and electric service providers—to demonstrate in both monthly and annual filings that they have purchased capacity commitments of no less than 115% of their peak loads. These purchase requirements are intended to secure sufficient commitments from […]

-

Coal

IGCC demonstration plant at Nakoso Power Station, Iwaki City, Japan

Integrated gasification combined-cycle (IGCC) power plants are not yet standard designs. Although they use mature coal gasification processes and combustion turbines, disparate technologies and equipment still require custom, laborious interfacing at each site. Every major gas turbine vendor now can point to one or more power-producing IGCC projects based on its prime mover, but none yet offers a "reference" plant that has standardized the interfacing enough to justify confidence in two key metrics: $/kW and availability. With an air-blown demonstration plant based on one of its 130-MW turbines, Mitsubishi Heavy Industries is looking to change the rules of this game.

-

Coal

Pleasant Prairie Power Plant Air Quality Control Upgrade Project, Pleasant Prairie, Wisconsin

We Energies’ Pleasant Prairie Power Plant is a good example of how existing plants retrofitted with NOx and SO2 removal systems benefit from early planning and action. P4, as everyone calls it, recently completed a multiyear project to add a selective catalytic reduction system to one of its two units and a scrubber to both. The unique design and contracting aspects of the project make Pleasant Prairie one of POWER’s top coal-fired plants of 2007.

-

Coal

Polk Power Station Unit 1, Mulberry, Florida

Ten years ago, POWER selected Tampa Electric’s 250-MW Polk Power Station and its revolutionary integrated gasification combined-cycle demonstration project as the magazine’s 1997 Plant of the Year. Although no new commercial IGCC projects have been built since then, interest in deploying the coal-gasification technology is getting traction in some parts of the U.S. In 2007, POWER recognizes Polk Unit 1 as a Top Plant for developing trailblazing O&M practices and technical improvements that enable it to operate today as reliably as a modern pulverized coal plant, with lower pollutant emissions.

-

Coal

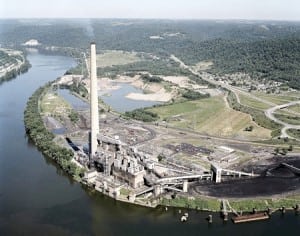

R.E. Burger Plant, Shadyside, Ohio

FirstEnergy’s R.E. Burger Plant has hosted a number of R&D projects over the years, but none as large as the demonstration of Powerspan’s 50-MW Electro-Catalytic Oxidation (ECO) multipollutant removal process a few years ago. Credit Powerspan for scaling up the demo unit and for adding CO2 as a target of a new pilot process called ECO2. And don’t forget the behind-the-scenes support of Burger’s plant staff and their willingness to incubate R&D projects while producing power. That’s what makes R.E. Burger a Top Plant in our book.

-

Coal

Managing air to improve combustion efficiency

The average pulverized coal–fired coal plant is more than 30 years old and has a heat rate in the neighborhood of 10,300 Btu/kWh operating with an "off-design" coal. Add a high load factor (or increased cycling service), squeezed maintenance budgets, reduced plant staff, and increased time between overhauls to meet the plant’s pro forma, and you’ve got major stress. Fortunately, there is a way to come in under your NOx budget and lower the stress. Breathe deeply and read carefully.

-

Coal

Harness detonation waves to clean boiler tubes

Air and steam sootblowers have been the power industry’s solution to the slagging and fouling of boiler convective passes caused by flyash and combustion products. Manual cleaning systems have been superseded by computers and neural nets, but the basic cleaning apparatus remained unchanged—until now. Say hello to detonation waves. They can knock those deposits loose while markedly improving boiler heat transfer efficiency.

Search