-

News

CWP Grounding Clamps

ERICO has developed a range of CWP grounding clamps that are ideal for use in applications including lightning protection, fault current ground, signal reference grid, and static ground. The clamps help minimize the possibility of damage from a lightening strike or other transient voltage by reducing the electrical potential between metallic objects and building systems. […]

-

Legal & Regulatory

Feds Must Deliver on Climate Change Legislation

For several years there has been widespread doubt about Washington’s ability to move forward with a national program to address climate change and reduce greenhouse gas (GHG) emissions. At various times during the Bush administration, it appeared that legislation might be possible, but it always collapsed under the weight of partisan politics and competing special […]

-

Coal

Top Plants: Bull Run Fossil Plant, Clinton, Tennessee

When TVA’s Bull Run Fossil Plant was erected in the mid-1960s, it could boast of having the largest boiler in the U.S., and the plant has enjoyed a long, enviable efficiency track record. Today the public judges coal plants by their emissions. Now that it’s been outfitted with the most advanced air quality control systems, including the latest flue gas desulfurization system design, Bull Run scores a perfect "10" in both categories.

-

Coal

Top Plants: Hirakud Power, Sambalpur, Orissa, India

Hirakud Power uses environmentally friendly circulating fluidized bed (CFB) combustion technology to produce electricity for one of the world’s oldest aluminum-smelting operations. This "captive power plant" has engineered a number of technical fixes to its original boiler designs to improve plant reliability and reduce outages and boiler repair costs. It also has made strategic investments in upgraded machinery to reduce auxiliary power consumption. In addition to an excellent environmental track record, as evidenced by being Asia’s first ISO 14001 (BS 7750) – certified power plant, Hirakud Power has solidified its position as an industry leader in CFB boiler operating experience and efficient power production.

-

Coal

Top Plants: Hutsonville Power Station, Crawford County, Illinois

This plant’s staff proves that a can-do attitude and high productivity can be compatible with a safer workplace. The proactive approaches they used at the 162-MW Hutsonville plant ranged from improving boiler efficiency to better managing risks to workers.

-

Coal

Top Plants: Nebraska City Station Unit 2, Nebraska City, Nebraska

Omaha Public Power District commissioned Unit 2 at its Nebraska City Station in May of this year. The new 682-MW unit joins Unit 1, which went commercial 30 years ago in the same month. The project is outfitted with all the requisite air quality control systems and sports a very good thermal efficiency. More importantly, the plant will provide reasonably priced power for customers of eight municipal utilities that share ownership of the plant’s electrical output. Those utilities paid for their portion of the construction cost and now receive a like portion of the electrical output from Unit 2 under a unique participation power agreement.

-

Coal

Top Plants: Rockport Power Plant, Rockport, Indiana

Hard work was required at the 2,600-MW Rockport Plant to make improvements to equipment, materials, and processes. But that hard work has paid off: The plant’s units operate much better, employee safety has improved, the facility is setting generation records with both of its 1,300-MW units, and it earned the PRB Coal Users’ Group Large Plant of the Year honors.

-

Environmental

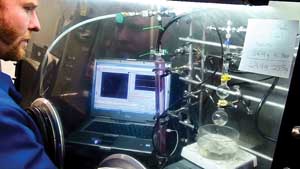

PNNL Pioneers New Sulfur and Carbon Dioxide Scrubbing Liquid

A reusable organic liquid developed by the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) to remove carbon dioxide (CO2) or sulfur dioxide (SO2) from power plant emissions could one day replace current scrubbing methods and allow power plants to capture the gases in a cost-efficient way that uses no water and less energy.

-

Coal

Top Plants: Seminole Generating Station, Palatka, Florida

Complying with a corporate environmental policy requires much more than just writing a check for equipment upgrades. It takes a dedicated and knowledgeable staff that’s willing to invest years of work to permanently reduce a plant’s environmental footprint. The staff of Seminole Generating Station have completed multiple, incremental plant improvements over the past decade that have significantly reduced air emissions and minimized solid waste disposal.

-

Nuclear

Using the Sterling Engine for Solar and Lunar Power

Since Robert Stirling invented the Stirling engine in 1816, it has been used in an array of specialized applications. That trend continues today. Its compatibility with clean energy sources is becoming apparent: It is an external combustion engine that can utilize almost any heat source, it encloses a fixed amount of a gaseous working fluid, and it doesn’t require any water — unlike a steam engine.

Search