-

Commentary

The Shale Gas Revolution Continues

The electricity industry is being transformed by the so-called “shale gas revolution” in the United States. Production of natural gas from shale rock using hydraulic fracturing (“fracking”) has boosted supply and reduced prices, making gas-fired power competitive with coal-fired power on price. Historically, coal-fired electricity generation has dwarfed generation from gas-fired plants in the U.S. […]

-

Instrumentation & Controls

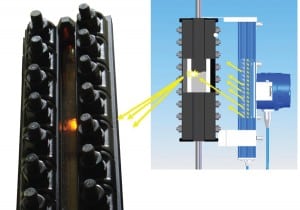

Drum Level Instrumentation Update

Accurate knowledge of the water level in any boiler drum application is an absolute necessity. While operating a boiler with low water level is one of the leading causes of boiler failure, operating with a high water level may produce less-than-optimal steam, as well as damage to the steam turbine by moisture carryover.

-

Legal & Regulatory

Is FERC Cracking Down on Market Manipulators?

Last October, the Federal Energy Regulatory Commission (FERC) announced that it was seeking a record $470 million penalty against Barclays Bank for manipulating California energy markets for several years in the late 2000s. The amount includes a $435 million fine as well as disgorgement of $35 million in profits Barclays gained from allegedly illegal trading. In addition, FERC levied hefty fines against several individual Barclays traders.

-

Nuclear

Too Dumb to Meter, Part 8

As the book title Too Dumb to Meter: Follies, Fiascoes, Dead Ends, and Duds on the U.S. Road to Atomic Energy implies, nuclear power has traveled a rough road. In this POWER exclusive, we present the 14th and 15th chapters, “A Man, a Plan, a Canal” and “The End of the Exploding Game,” the final two chapters of “Eddie Teller’s Exploding Ambitions” section.

-

O&M

Layup Practices for Fossil Plants

Improper layup practices are a major contributor to boiler tube failures and to steam turbine pitting and cracking in U.S. fossil plants. EPRI’s research into identifying damage mechanisms, utility best practices, and innovative new methods to protect plant equipment during outages will aid plant operators in achieving a successful layup.

-

Instrumentation & Controls

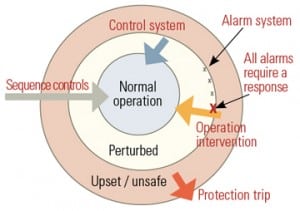

Plant Automation Advancements: The Australian Experience

Many recent utility greenfield and rehabilitation power projects have incorporated plant automation, with the goal of reducing the number of operators needed. The essential design principle is to specify control systems and field devices that will achieve the desired operational regime. Here’s how it’s done “Down Under.”

-

Instrumentation & Controls

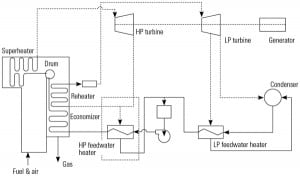

Coordinated Feedwater Heater Energy Control

The increased use of intermittent renewable energy sources and the shift to gas-fired combustion turbines places new burdens on the dispatch of many coal-fired units. Steam units must now operate at very low minimum load while maintaining the ability to ramp up and down quickly. High-pressure feedwater heater energy control can improve the system response of such coal-fired units.

-

Instrumentation & Controls

Thermocouple Response Time Study for Steam Temperature Control, Part II

Mismatched or poorly maintained temperature sensors and thermowells can cause an often-unrecognized error in steam temperature measurement. The problem is often recognized only when sluggish steam temperature response times are noticed. Recent tests suggest some simple ways to resolve the problem.

-

Environmental

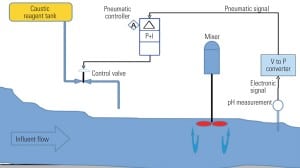

Sediment Pond Effluent pH Control

Many power plants have sediment retention ponds that require control of pH for the effluent. The following guidelines for fossil plant sediment pond pH control will help you design a robust system while staying within budget.

-

Business

Getting Distributed Energy Resources Right

Rick Tempchin, executive director, Retail Energy Services for the Edison Electric Institute, talks about the impact of distributed energy resources on utilities and their customers.

Search