Owner/operator: Rosenergoatom

Fast-neutron reactors are pivotal to Russia’s ambitious nuclear power plans. The successful construction, grid-connection, and testing of the country’s first BN-800 reactor at its Beloyarsk nuclear plant is a major achievement in the right direction.

Since the Soviet Union began its first experimental nuclear power projects in the 1940s, Russia has embraced nuclear’s potential, staking its energy future on the power source and blazing nuclear technology trails that have been followed by several countries around the world.

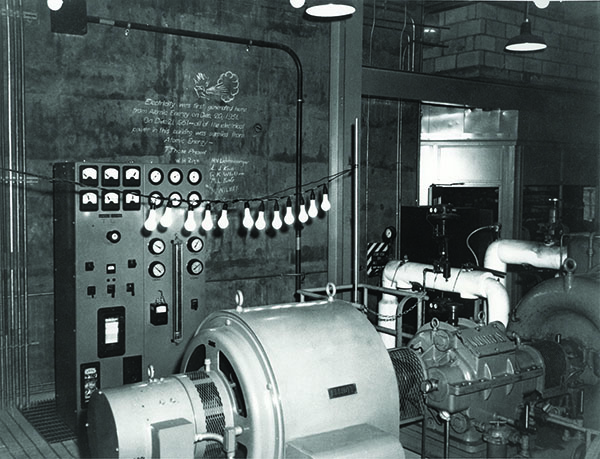

Though the first reactor to produce any amount of electricity was the experimental breeder reactor at the U.S. Argonne National Laboratory in December 1951, the Soviet Union developed the world’s first nuclear reactor to produce electricity at any significant scale at Obninsk, a 5-MWe channel-type uranium-graphite design. It produced electricity from 1954 to 1959. The success of this plant spurred more research and development of different types of nuclear reactors, including pressurized water reactors (PWRs), boiling water reactors (BWRs), channel-type BWRs, and organic-moderated and cooled reactors.

Although some reactor types were abandoned before they reached the prototype stage, efforts to develop thermal nuclear power reactor concepts paid off, resulting in PWR prototypes being built at Novo-voronezh, two channel-type reactors at the Beloyarsk plant in the Ural region, and the Dimitrovograd BWR. By the late 1960s, drawing on accumulated experience, the Soviet Union decided that it would focus future development on two thermal reactor types: the VVER PWR and the RBMK light water graphite reactor. Today, the country has 36 reactors of these types operating for a total 26 GWe: 19 VVER PWRs, 13 RBMK reactors, and four small graphite-moderated BWRs.

From the outset, the Soviet Union also paid special attention to the development of fast-breeder reactors (FBR), which generate more fissile material than they consume. According to the International Atomic Energy Agency, the Soviet Union’s fast-neutron reactor program began at the end of 1949, when physicist Alexander Leypunsky called the government’s attention to the technology’s potential to address a uranium shortage that was projected if the Soviet nuclear military industry expanded per its large-scale, long-term plans.

In 1955—just a year after Obninsk started up—the first Soviet experimental FBR, Bystry Reactor-1 (BR-1), using metallic plutonium fuel went into operation. The following year, BR-2 started operations, followed by BR-5, a liquid sodium–cooled reactor fueled with plutonium dioxide that operated until 2004. In 1969, a 12-MWe test prototype fast-neutron reactor with sodium coolant—BOR-60—started operations at the Institute of Atomic Reactors in Dimitrovograd. By 1972 the BN-350, a demonstration unit fueled with uranium enriched up to 20% to 25% uranium-235 and mixed oxide uranium-plutonium (MOX) test fuel assemblies had started operations.

Even though that reactor suffered a major sodium fire, the government pushed for a second, larger fast-neutron reactor drawing from BN-350’s technical achievements, and around 1981, the BN-600 started up as the third unit at Beloyarsk. As that unit was being built, the Soviet government vetted designs for two even larger FBRs: BN-800 and BN-1600. Citing the fairly smooth construction of the BN-350 and BN-600 reactors—owing largely to the manufacture of pumps, vessels, piping, reactor covers, and steam generators at Soviet plants—the government charged ahead with plans to build five BN-800s in the Urals region.

In 1986, however, the Chernobyl disaster struck, and the Soviet Union quickly pared back its nuclear power ambitions. Then, in the 1990s, reeling from the Soviet Union’s collapse, Russia sank into a severe economic depression, unable to support substantial investments in new nuclear projects. In that period, FBRs suffered, unable to compete economically with Russia’s light-water and graphite-moderated thermal neutron reactors. Another problem: Supplies of high-grade uranium had increased sharply as a result of new uranium deposit discoveries in Kazakhstan during the 1960s and 1970s.

In 1998, Russia’s slumbering economy awoke and began growing at an unprecedented annual gross domestic product growth rate of 6% over the next decade. Soaring electricity consumption soon highlighted the country’s dilapidated power infrastructure. As the country embarked upon reforms (see “The Russian Power Revolution” in POWER’s January 2013 issue), in 2000, President Vladimir Putin unveiled a new program for the expansion of Russia’s nuclear capacity. The program focused mostly on light-water reactors, but it also called for the commercialization of FBRs, outlining the construction of a few BN-800 reactors and design of a commercial prototype of the BN-1600.

Construction Kicks Off

Today, Russia’s fast-neutron reactor program continues to be integral to the development of a closed uranium-plutonium fuel cycle whose MOX fuel will be reprocessed and recycled. As well as producing chain-reacting uranium-233 from neutron capture in thorium blankets as a potential fuel for thermal-neutron reactors, state-owned nuclear entity Rosatom’s “Proryv”—or “Breakthrough”—program seeks to significantly reduce volumes of highly radioactive waste that will need to be stored in a permanent geological repository. According to the World Nuclear Association, the country anticipates that 100 GWe of nuclear capacity will require only about 100 metric tons (mt) of input per year, from “enrichment tails, natural uranium and thorium, with minor actinides being burned. About 100 [mt per year] of fission product wastes go to a geological repository,” it says.

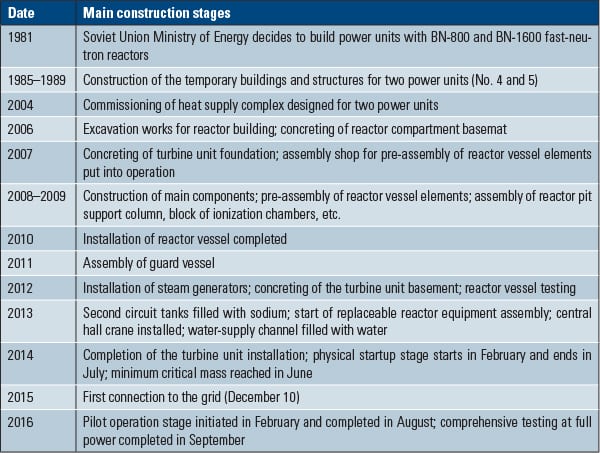

Pivotal to Russia’s plans was construction of a BN-800 fast reactor designed by Rosatom’s nuclear engineering arm OKBM Afrikantov, which finally kicked off as the fourth unit at Beloyarsk in 2006. Construction was spearheaded by general civil contractor Uralenergostroy. Though it encountered delays owing to funding issues, the unit’s construction schedule was mostly smooth, helped along by onsite assembly of key components (Table 1).

|

|

Table 1. Main construction stages. Source: Rosenergoatom |

Beloyarsk 4 achieved first criticality in June 2014 and was grid-connected in December 2015. On February 9, 2016, Rosatom reported that the unit had completed all tests under a “first” 72-hour test-period at 50% power. By August 18, 2016, the unit started operating at 100% power for the first time. During its ascent to full power, the reactor—which is 2,100 MWt, 864 MWe gross, and 789 MWe net—already had generated more than 1.3 TWh of power, and it is expected to produce 3.5 TWh by the end of 2016, said plant operator Rosenergoatom, Rosatom’s power station operations subsidiary.

This September, the unit underwent “comprehensive” testing at its rated power, a procedure that “is a major and final condition in preparation for the delivery of power in commercial operation,” Rosenergoatom explained. With the 15-day comprehensive test that was undertaken by more than 1,200 Russian specialists and witnessed by 20 observers from seven foreign countries, “the power block has been confirmed to be capable of dealing with the rated capacity within the designed parameters without any deviations,” it said.

With that test complete, Rosenergoatom will be required to obtain permission from Russian nuclear regulator Rostechnadzor to operate the reactor commercially. “Afterwards, the Rosatom Corporation will draft a resolution approving the power block’s commissioning. All of those procedures are planned to be completed in September 2016,” Rosenergoatom said.

On the Edge of Technical Development

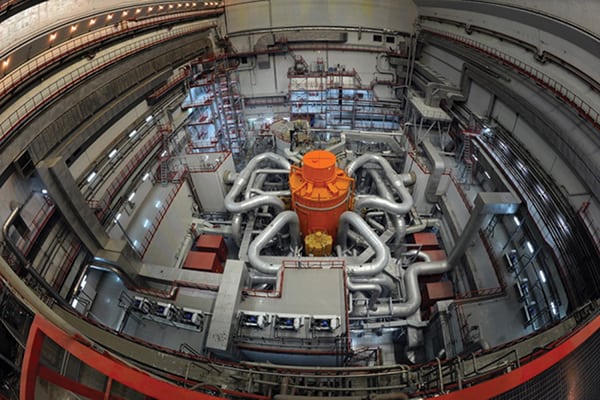

Putting Russia’s BN-800 unit online has been a source of pride for the country (Figure 1). “The Beloyarsk [nuclear power plant] is on the edge of technical development. No other country boasts such [a] track record in fast reactors,” noted Andrey Dementiev, deputy CEO and director of Rosenergoatom Concern’s nuclear power plant production and operation department.

The unit is essentially a fast reactor with a sodium coolant and a turbine unit. But as the BN-800 unit’s general contractor, Russian engineering firm SPbAEP, specifically highlighted, it is unique because it enables a number of uses. The BN-800 power unit is designed for the production of heat and power, and as part of the grid, it operates at constant rated load. However, it can also be used for plutonium consumption and, if necessary, production; the processing of long-lived supertransuranics accumulated in the radwastes of reactors of any type; as well as the production of isotopes. “No other reactor type combines so wide a range of functions,” it said.

While the BN-800 design retains all key legacy solutions offered by the now 30-year-old BN-600 reactor design, it employs new, noteworthy concepts. Rosenergoatom explained that the BN-800 has a rated 2,100 MWt compared to the BN-600’s 1,470 MWt, which was achieved without substantial changes in the reactor pressure vessel design. It also uses steam reheating and improvements in auxiliary systems to considerably decrease the metal intensity of the project—which in turn enhances its competitiveness. Compared to the BN-600, the reactor has an additional passive safety system consisting of three absorber rods that are hydraulically suspended in sodium flux, which would drop into the core if sodium flow decreases to 50% of rated level. And it has a passive system of residual heat removal through air-heat exchangers that are connected to every loop of the secondary coolant circuit, as well as a corium catcher that prevents fuel from dropping onto the bottom of the reactor pressure vessel and prevents its release outside the primary coolant circuit in case of a beyond-design-basis accident.

The Beloyarsk BN-800, like its sister BN-600 unit, has become pivotal for the transformation of weapons-grade plutonium into standard spent fuel. The site is located in the vicinity of a nuclear recycling facility at Mayak, which “could assist to settle economical and, primarily, environmental issues associated with the storage of plutonium,” Rosatom said.

Rosenergoatom is now mulling further expansion of the Beloyarsk plant with the construction of a fifth unit, possibly a 1,200-MW fast reactor. Many infrastructure facilities built on the BN-800 unit site are designed for two power units, the company noted. “And the team of builders, which accumulated experience in the course of BN-800 construction, will apply its skills at the next power unit construction,” it added. For now, the company will continue monitoring operations at the BN-800 unit and bask in the achievement of commercializing a cutting-edge technology that has been decades in the making. ■

—Sonal Patel is a POWER associate editor.

Editor’s note: Rosenergoatom commissioned the BN-800 unit at the Beloyarsk nuclear power plant on November 1, 2016.