Lock in safe, reliable operations by opening the door to third-party expertise

There’s still a big takeaway from a 2008 Florida blackout, and it’s not the size of the fine that followed. Although it was the largest penalty levied under the new reliability standards at that time, here’s the bigger elephant in the room: Florida Power and Light believed it was in compliance with the recently updated (2007) reliability standards at the time of the blackout.

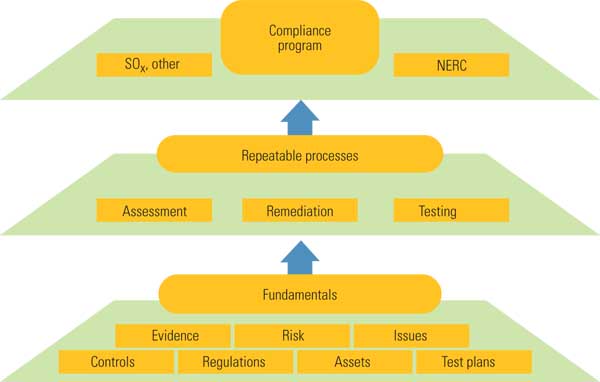

Whatever technical lesson we can learn from the circumstances that caused that blackout, the lesson for reliability is clear. Ensuring compliance to changing regulations–and comprehensively documenting that compliance in case of incident review–takes timely, deep and detailed attention. Since 2008, compliance issues have only become more complex, with regular updates and additions. Evolving technology and growing risk profiles put a lot on power generators to manage, and trends in the labor market for technical experts that energy businesses need are making it more difficult, and more costly.

Deloitte reports that energy companies have seen a sharp increase in full-time employees (FTEs) supporting North American Electric Reliability Corp. (NERC) compliance, with the percentage of those employing 11 or more FTEs growing from 19% in 2015 to 50% in their 2018 report. All in all, the costs of compliance are going up. In 2015, 3% of firms had NERC compliance budgets over $10 million, while 31% had under $500,000. In 2017, 14% had budgets over $10 million, while only 3% were still below $500,000.

Comparing the financial industry’s response to similar trends,Thomson Reuters’ Cost of Compliance Report 2018 notes that almost two-thirds of responding financial firms expect their total compliance budget to increase. But that report also hints at a solution: almost one-quarter of those firms now outsource some or all of their compliance needs.

Why Outsource Compliance and Reliability?

The fact is simply that on-site staff face ever-increasing reliability responsibilities, often with fewer resources than they had in previous years. NERC compliance is a highly visible trend but it’s not the whole reliability story. Many facilities have moved reliability needs into a protective devices program, often rolled up into their maintenance program, where teams with a defined operational scope just don’t have the training, tools, or time to completely and safely maintain and test all those devices. While not covered directly by NERC compliance activity, those devices directly impact reliability and safety.

There may be hundreds of devices at that level that can’t be tested until a scheduled outage, when there’s no time for on-site staff to test so many. A convergence of trends in power generation have led to a shortage of skilled workers ready to answer reliability and compliance requirements. Answering that deficit intelligently, however, can greatly benefit an energy business. Third-party electrical testers and maintenance experts specialize in both compliance and reliability, while bringing focused resources and equipment to bear that not only answer those needs but introduce efficiencies and risk mitigation that improve profitability.

Bridging the Talent Gap

While safety and reliability regulations grow, deregulation elsewhere has changed the landscape of power generation ownership. Institutional knowledge once secured by the continuity of owner-operators is less simple to track for investors and managers. But that sea change could be a blessing in disguise.

With experienced technicians retiring and the costs of replacing them increasing, keeping enough compliance and reliability expertise on hand has become expensive and time-consuming. On the other hand, supplementing those roles with third-party talent not only mitigates those costs, but answers a key weakness of institutional knowledge: a narrow focus.

Even the most talented in-house experts are dealing with one system. A third-party reliability expert has experience with multiple facilities and multiple systems. They can objectively compare an interpretation of a compliance edict or a safety protocol to interpretations and safety rules they’ve seen, worked with, and consulted about elsewhere.

Instead of waiting for in-house teams to amass new institutional knowledge needed to protect reliability, invite in a team that’s seen auditors respond to a program. A wealth of institutional knowledge built by an experienced testing partner puts your process ahead of the game.

How Many Hats Is Too Many?

One result of talent attrition in power generation is that compliance tasks often get rolled up together, like a stack of hats landing on one–or a few–unlucky heads. Except that electrical system reliability is highly technical, and that new hat doesn’t come packaged with a degree in electrical engineering. Since NERC compliance takes a highly specialized background, and reliability across all electrical systems, high-voltage or not, involves countless interdependent assets that a compliance leader–or team–is relying on someone else to provide that expertise.

With turnover and downsizing, compliance teams may not have that level of expertise on their operational teams to fall back on. Solving that problem, however, could be an opportunity to introduce more efficiency. With so many hats for the compliance team to wear, the potential for each compliance area to grow generates a geometrically expanding set of responsibilities. Keeping such a monumental and technically difficult task as NERC compliance off their plate is a huge boon, cutting the time and expense of re-inventing the wheel out of your total compliance budget.

A third party can step in and supply the breadth and depth of knowledge needed to create technical procedures. In some cases, the amount of detail needed to fully satisfy reliability requirements amounts to commissioning the system as if it was new. Given the amount of safety assets and electrical equipment needing testing or verified maintenance, that may seem like a tall order. Experienced testing partners will have the scope to execute the level of detailed work needed, with sufficiently trained teams and safety gear.

Equipment On Hand

Human resources aren’t the only resources lost by compliance teams in recent years. Due to many organizational changes, energy generating facilities may no longer own or have access to testing equipment they need. In previous business configurations, the facility may have been able to rely on testing teams or testing equipment that are no longer part of their current organization.

That’s also a problem that turns out to be an opportunity. In this case, power generators can upgrade to a third party’s equipment without incurring those costs. As technology updates, and the scope of data collection requirements grow, newer measurement and testing technology has grown to meet those needs. Purchasing that equipment and training on-site staff to operate it for the facility can be cost-prohibitive. A third party can bring the equipment, let their experts collect and analyze the data, and then remove the equipment from your facility. That’s fewer assets to care for.

Keeping Compliant Means Keeping the Records

Today’s due diligence means data. Regulators and auditors want to see every detail about every device. Previously, trip checks might have been enough. Critical circuit tests might have resulted in yellow-lining prints, where a circuit was initialed and dated, but nowadays, that would only lead to the question: “I see it’s yellow-lined, but what did you actually do?”

Replacing those initials and dates with all the relevant data creates a mountain of information to track. How the test was performed, exactly what was done, equipment used, every measurement–all that data must be captured and made available for intelligent review.

To create modeling data for dynamic ratings, special software and equipment is needed to monitor the data while the plant is running. As the grid evolves, the energy ecosystem changes, and each facility needs new testing to be done to replace modeling data and dynamic ratings.

Both of those needs depend not just on the best testing equipment and the knowledge needed to use it effectively and safely, but the operational capacity to collect, analyze, and process that data properly on your behalf so that you have clear, organized due diligence ready for auditors to digest.

The ever-deepening requirements for data may look like an ever-expanding liability, but it’s actually an opportunity to mitigate risk. Justifying the return on investment for maintenance and testing dollars in terms of asset life can become an exasperatingly technical dive into the details of proactive maintenance for a wide range of equipment. But the reliability and risk mitigation case is clear when you rely on due diligence done and signed off on by an accredited, expert third party. That’s the risk of million dollars per day per violation, as backed by federal authority, answered with sure, safe results.

Invite an Accredited Reliability Partner

The talent gap facing the power industry, and the subsequent pressures on labor costs, may be less of a drag on profitability, and more of an opportunity to make a clear and compelling business case for outsourcing compliance. That could deliver not only huge operational savings for your compliance teams but also provide substantially superior risk mitigation than an in-house team could cost-effectively provide.

To ensure those improvements to compliance and reliability, seek out an electrical testing and maintenance partner with the experience needed to advise your teams and the business scope to supply the manpower, equipment, and reporting power you need. A qualified partner should have certified, trained technicians and an accreditation from a respected standards organization, such as NETA (the InterNational Electrical Testing Association).

—Christopher Smith is a general manager at ABM Electrical Power Solutions. Smith has served in management positions at ABM for more than six years. Prior to joining ABM, he was a maintenance engineer for Duquesne Light Co.