Complying with reliability standards requires considerable resource planning. The tools and suggestions provided here may help engineers conform to new generator relay loadability requirements. But compliance isn’t the only reason to be an early adopter; doing so can also avoid unnecessary downtime and reduce maintenance costs.

If you are the owner or operator of a generation facility connected to the bulk electric system (BES), starting a new year may trigger some anxiety regarding regulatory requirements. In particular, the October 2019 deadline to demonstrate compliance with the North American Electric Reliability Corp.’s Generator Relay Loadability Standard (NERC PRC-025-1) just got a little closer. But not to worry, there are resources that can streamline the work required and make your job a little easier.

PRC-025-1 is just one of the reliability standards created following the 2003 electric power blackout that affected 50 million people in the U.S. and Canada. As the most widespread blackout in North American history, it is estimated to have cost between $7 billion and $14 billion. The event clearly exemplified the vulnerabilities of the BES and the need for regulation.

An analysis of this blackout and other major disturbances in the past 25 years revealed that generators tripped for conditions that did not pose a direct risk to those generators and associated equipment. In many cases, this tripping was found to have expanded the scope and/or duration of these disturbances.

PRC-025-1 was created to increase grid stability during system disturbances by reducing the number of nuisance trips due to incorrect settings. According to the State of Reliability 2015 report, 31% of all misoperations resulting in unplanned hours (UH) or forced outage hours (FOH) were due to incorrect settings, logic, or design errors.

Like many reliability standards, PRC-025-1 is currently enforceable by law. Achieving compliance is mandatory and can take a significant amount of time. Noncompliant facilities may need to budget for system modifications or incorporate changes during a planned system outage. The consequences of not demonstrating compliance by the deadline are significant. The Federal Energy Regulatory Commission can impose fines of up to $1 million per violation per day.

Realize the Benefits of Early Adoption of PRC-025-1

It is important to start planning your compliance efforts now. Early adoption of PRC-025-1 and other reliability standards helps generation sites remain competitive in the energy market and attractive to investors. By avoiding UH or FOH due to misoperations, and subsequently reducing the equivalent forced outage rate, facilities can achieve increased revenues, as well as lower operational, maintenance, and repair costs.

Another reason to start early is to have access to qualified engineering resources. The sheer nature of today’s deregulated BES has driven generator owners and generator operators to streamline workforces in order to reduce overall operational costs while increasing reliability and the availability to produce. This strategy often results in operating with limited engineering resources. Under typical conditions, this approach is economic and appropriate. However, with looming compliance deadlines, working with limited engineering resources can prove challenging.

Because regulatory requirements governing operations continue to change, single-site generators that have a lean workforce will likely need to rely heavily on external or outsourced engineering resources, such as contractors. Multi-site generation entities often already utilize an engineering team specializing in matters pertaining to NERC compliance. However, they may also need additional assistance if their engineering team is focused on disseminating new standards to the fleet and preparing for audits, rather than on the highly technical tasks needed to meet new regulatory requirements.

Determine the Extent of Needed Resources

As requirements for system stability and loadability are enacted, a surge in demand for engineering support of a much more technical nature becomes apparent. However, you may not know the precise scope of your efforts without first considering compliance options or performing a preliminary assessment.

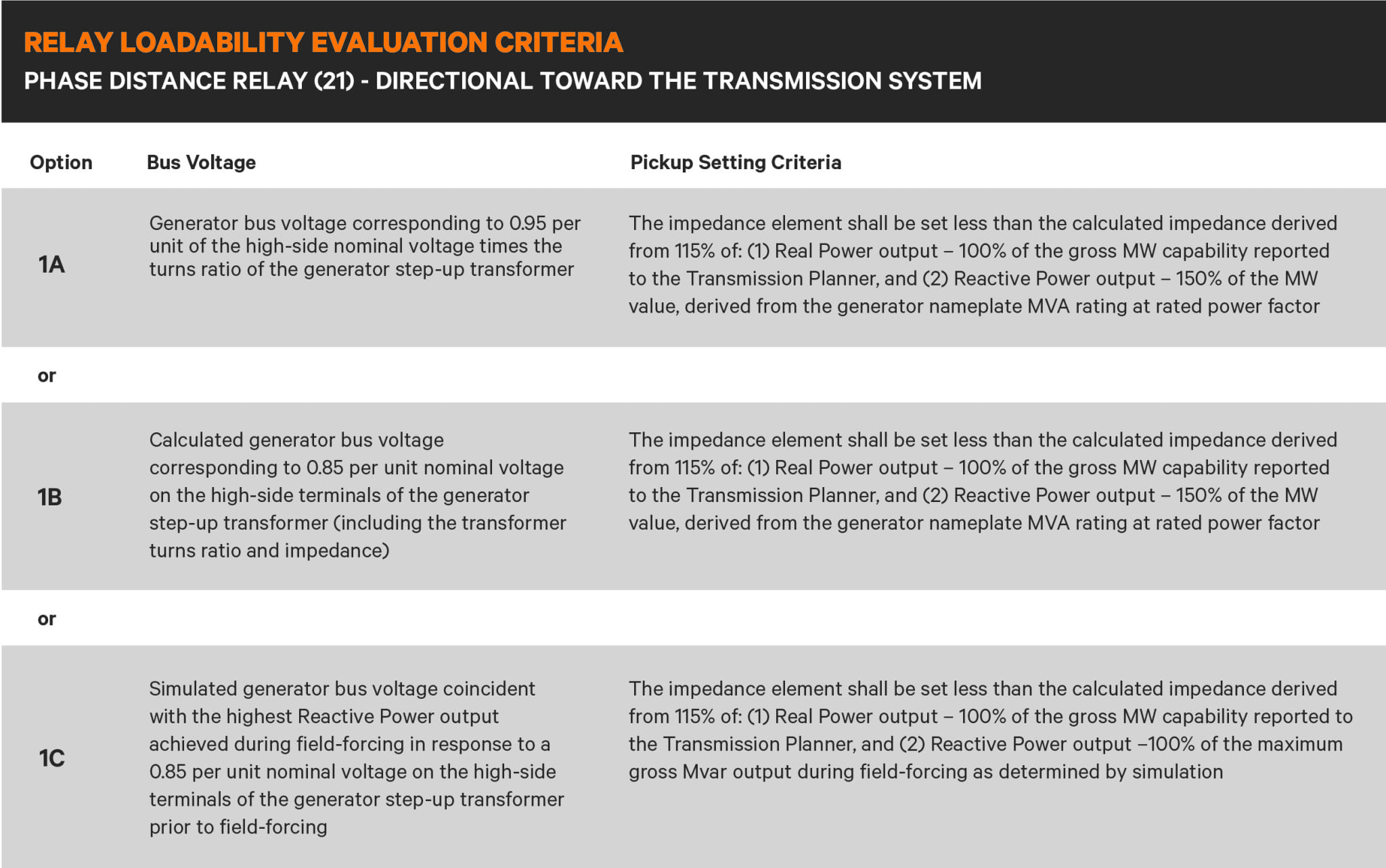

PRC-025-1 provides multiple options for setting load-responsive protective relays, as outlined in Attachment 1, Table 1 of the application guidelines. Each relay may have up to three options available—A, B, and C. Table 1 illustrates the requirements for the phase distance relay (21), including three compliance options.

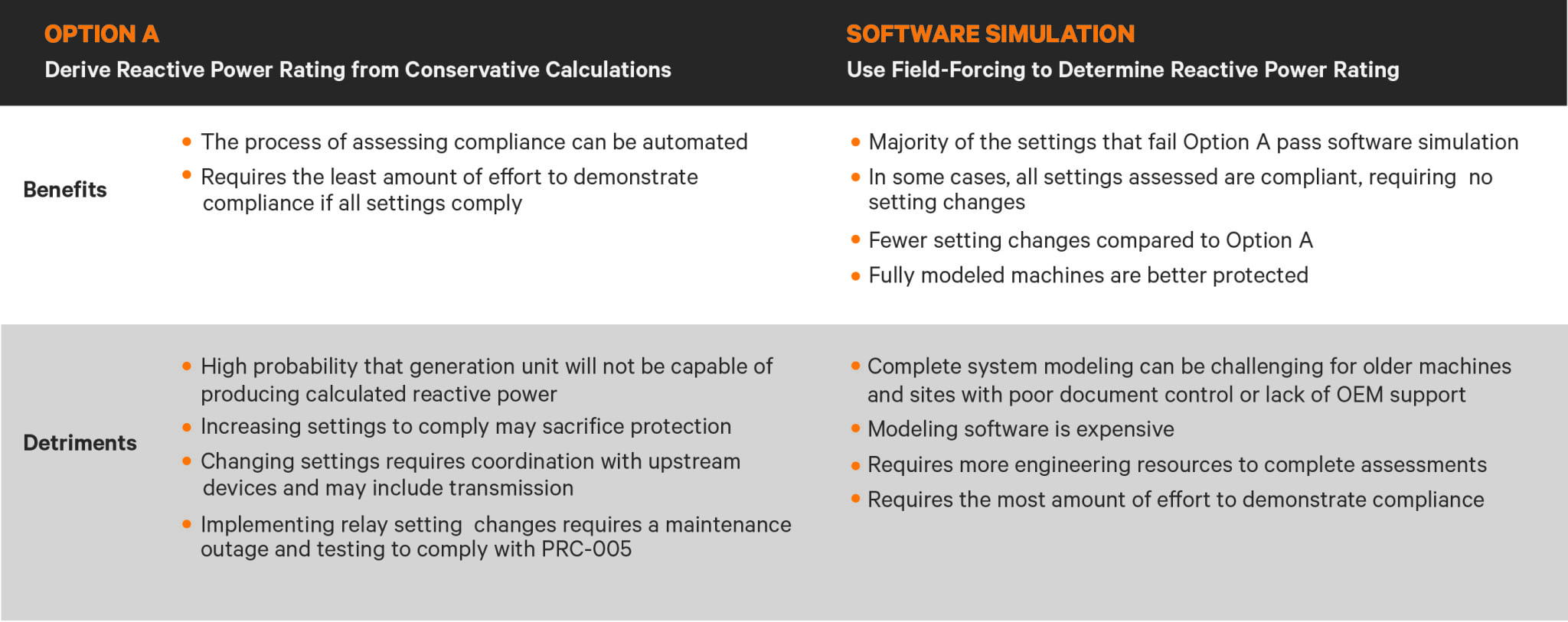

This article focuses on two options. The first is Option A, which is the simplest to apply, but it generally results in a less-accurate assessment. The second, referred to as “software simulation” (and either Option B or Option C in the application guidelines), is more accurate because it models the machine’s reactive power capability using field-forcing simulations. You should evaluate the benefits and drawbacks of each option, summarized in Table 2, when determining which approach is best for your generating facility.

Given the conservative nature of the criteria in Option A, which may not be achievable by all generating units, an alternative method—software simulation—was created to determine the reactive power capability. Option A requires less engineering effort, yet it may not provide the most accurate assessment of generator capability. Although this option does help to improve grid stability, it is less accurate than software simulation and may not provide optimal generator unit protection.

In these cases, the thresholds of the load-sensitive relays typically need to be increased, which requires coordination with the transmission system prior to implementation. This coordination effort may take as much or more time than what would be needed to simply perform software simulation from the start. Additionally, any changes made to protective relay settings must be fully tested at the time of implementation, which generally requires the generation site to take a maintenance outage.

For the average single-unit plant with limited engineering resources, the process of assessing how close a system is to compliance can be quite a challenging task without assistance. Even for the multi-site owner with a dedicated NERC team, the task of analyzing tens, or even hundreds of sites, is a significant effort without a systematic process and supportive tool for making initial assessments. Some owners might elect to centralize engineering resources, but this typically translates into less familiarity with each site and limited data-gathering capacity.

Streamline Efforts with a Systematic Process and Support Tool

PRC-025-1 application guidelines carefully detail the steps necessary to assess compliance using Option A. This process must be performed for each site and requires a significant amount of effort to manually perform each time. A quality assessment tool will automate tasks of the process that require little supervision and are repeatable from project to project.

Although engineering teams could create their own tool, the engineers of Vertiv’s Electrical Reliability Services (ERS) have already done the work to help generators simplify the assessment process and encourage early adoption. This downloadable tool reduces the compliance-checking steps to the most essential components and makes the assessment process scalable for all generation site configurations.

By working through the following six-step procedure, using the ERS tool, you’ll be better able to plan the effort, time, and cost needed to meet the NERC standard’s requirements.

Step 1: Gather Generation Unit Data.A minimum amount of information should be collected prior to performing assessments of the relay settings. This basic generation unit information is used throughout the assessment process. Required information can be found in the following documents: one-line drawings, three-line drawings, protective relay settings, relay test reports, and component nameplates. Each document will contain key information, such as the following:

■ Maximum rated megavolt amperes (MVA) for the generator

■ Rated power factor and voltage

■ Maximum MVA for generator step-up (GSU) and unit auxiliary transformer, and associated impedances

■ Rated primary and secondary voltages at the set tap position for the GSU

■ Utility voltage

■ Megawatts reported to the transmission planning coordinator

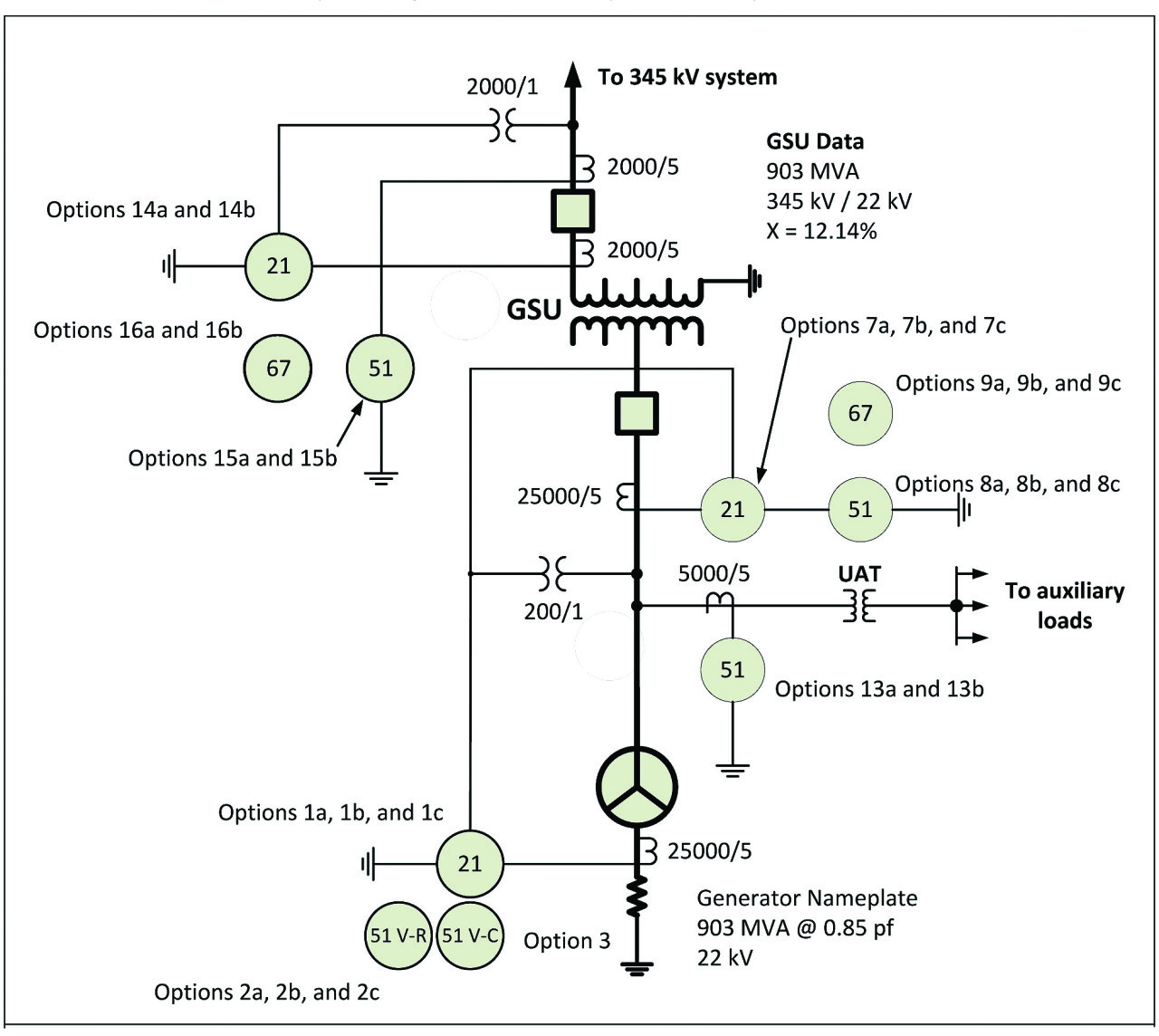

Step 2: Determine Which Load-Sensitive Protective Relays Within the Generation Unit Will Require Study for Generator Loadability.PRC-025-1 application guidelines illustrate an example protective relay scheme for a generation unit. This scheme is comprehensive in order to assist users in determining how the standard applies to a given plant. However, not all relays illustrated will necessarily exist in every system (Figure 1).

Once the generation system protective relays have been sorted into the appropriate options as seen in Figure 1, the remaining protective device information is gathered to assess each protective relay’s compliance. This information is also found within the documentation gathered in Step 1.

Step 3: Populate Each Tab of the Tool with Data. Using the basic unit information gathered in Step 1, enter data into the nameplate tab of the assessment tool. Continue this data entry on the corresponding tab for each protective relay identified in Step 2.

The tool delivers a “compliant” or “not-compliant” assessment for each synchronous generator relay by comparing the protective relay settings with Option A of the standard, which derives the reactive power rating from conservative calculations. Additionally, the minimum settings required to become compliant with Option A are also calculated and presented. This gives the user valuable information indicating how close each load-sensitive relay setting is to Option A compliance.

Step 4: Decide Whether to Demonstrate Compliance to the Standard Using Option A or Using Software Simulation. If choosing Option A, you will need to make necessary adjustments to protective relay settings and create the reporting necessary to demonstrate compliance. If you want to ensure more accurate relay settings that improve generating unit protection, you should investigate further through field-forcing. This will allow you to model the machine’s reactive power capability during a transient sufficient enough to lower utility voltage to 85% of steady-state values.

Once an approach has been selected, the original equipment manufacturer and the protection engineers responsible for upstream coordination should carefully review any changes to the existing settings prior to implementation.

Step 5: Perform Corrective Actions as Needed. Whether determining the reactive power rating through conservative calculation or through software simulation, corrective actions will likely need to be taken. Actions will include scheduling an outage for implementation, testing, and documenting protective relay setting changes.

Step 6: Compile All Information to Complete the Demonstration Report. A thorough report for generator loadability will contain all information that was gathered during the assessment phase; supportive calculations from PRC-025-1 application guidelines; results from the software simulations (if performed); and documentation of any corrective actions and testing.

Assimilating reporting characteristics that make the auditing process efficient will contribute to a successful audit with the Electric Reliability Organization. Reporting methods that support a searchable document such as an electronic format employing optical character recognition conversions, a linked table of contents, bookmarking, and embedded links to supportive documentation should be an integral part of the demonstration report. These attributes allow an auditor to quickly navigate through the report to find critical information.

When reviewing reports, an auditor will be more likely to recognize formulas similar to those published in PRC-025-1 application guidelines, so all calculations should follow the guidelines as closely as practical. A high-level summary of all load-sensitive protective relays should be listed in a format that clearly shows the reader which relays were considered as part of the generator loadability study and which were not applicable.

Whatever your approach to achieving PRC-025-1 compliance, there are a few actions that will clearly benefit your business. By choosing to adopt the standard early, working with qualified engineering resources, and leveraging available assessment tools, you can simplify the compliance process. And you can feel good about doing your part to better protect the grid while effectively protecting your own operations. ■

—Steve Nollette is supervising engineer for Vertiv Services (NERCcompliance@VertivCo.com).