Getting proper sag between power line towers can be time-consuming. However, a new surveying tool allows workers to make adjustments in real-time. The method saves time and money, while also providing excellent 3-D documentation of the end result.

For surveyors, the unexpected in the field is not usually welcome. Surprises lead to challenges to resolve, time delays, and often increased costs.

But occasionally there are pleasant surprises. Like when Even Sellevoll, a survey engineer with Norwegian company Geomatikk Survey, set up his integrated total station and scanner instrument to survey a power line, and it revealed a capability he wasn’t aware it had. That unexpected discovery completely changed his approach to the survey assignment—in a good way.

The project required Geomatikk Survey to measure and adjust the sag of new, high-voltage power lines on a mountain in Sogn og Fjordane, a county in western Norway (Figure 1). The original strategy was for Sellevoll and his colleague, Svein Ivar Vestbø, to use the company’s newly acquired Trimble SX10 scanning total station to acquire the needed measurements and process the data to calculate how much adjusting the lines needed. However, “When we pointed the SX10 at the first power line, the sensor automatically locked on to the line itself, even though there was no prism,” explained Sellevoll. “That was very interesting because we didn’t know that it would do that. What that meant was we could not only more easily and accurately survey the lines, we could adjust their sag in real time, directly in the field.”

|

| 1. Simply accessing power lines in remote mountain areas can be difficult. Courtesy: Geomatikk Survey |

And just like that, a project originally scheduled for several days’ work was suddenly reduced to a single day. The new technology was not only a game-changer in the field, it is proving to be the business development tool it was acquired to be: an instrument to redefine real-time surveying and to reap the revenue benefits of new business opportunities.

Real-Time Measuring and Monitoring

Late last year, Sellevoll and Vestbø climbed into a helicopter and flew up 600 meters to the top of a mountain in Leikanger, a small town on the northern shore of Sognefjord, the longest and deepest fjord in Norway and the second-longest in the world. Hanging above the steep, angular surface of the mountainous terrain was a 450-meter-long section of four power lines that their customer, BKK Enotek, had just installed. After installing the cables, BKK had tried to determine and set the appropriate sag levels using a traditional sag scope. But the precipitous landscape and the span between the two towers made it too difficult to accurately calibrate the lines.

The Geomatikk Survey crew took on the task of measuring the sag and assisting BKK in correcting the sag elevation to meet the height and tension tolerances. To spatially ground the project data, Sellevoll and Vestbø used their Trimble R10 GNSS receiver and SX10 total station technology to establish control.

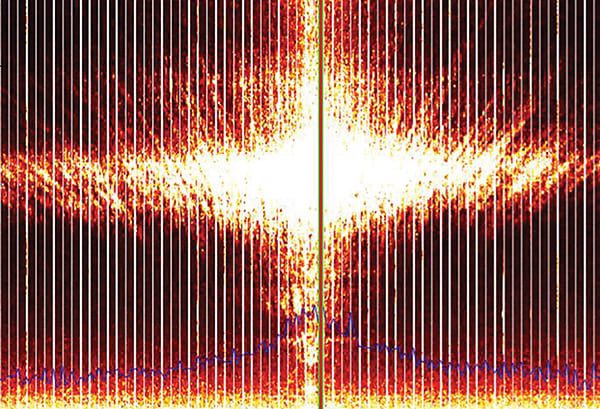

Standing beneath the utility tower at one end of the line, they aimed the SX10 directly overhead and collected a point where the cable connects to the tower, a process they repeated for each power line. They then set up underneath the other tower and acquired four more connection points (Figure 2). With the instrument’s controller, they determined a chord (straight line) between each power line’s end points and established a vertical offset from the chord down to the existing power line. Given the length of the cables, their above-ground height of 25 meters (m), and the current temperature, which was about 17C, BKK specified that each cable’s sag needed to be 6.26 m below the chord at the lowest point.

|

| 2. Using a Trimble SX10 scanning total station to acquire needed measurements and process data, workers were able to determine needed line adjustments in real-time. Courtesy: Geomatikk Survey |

“The ability to see and compare the chord line with the existing power line on the controller’s big screen enabled us to see in real time how much each line was outside of tolerance,” Sellevoll said. “So, when they adjusted and lifted the cable, we could monitor it on the controller and see that it needed 50 centimeters more or 10 centimeters more until it was in the correct position.”

Measuring to an accuracy of plus or minus 3 centimeters, the Geomatikk Survey team determined that each of the four power lines was hanging too low, between 1.5 m and 2 m below the acceptable sag limit. With a BKK crew positioned at the transformer station down in the valley, Sellevoll and his colleague instructed the tensioning team via telephone.

Starting with line one, he aimed the SX10 and once it had locked onto the cable, he told the crew how much adapting it needed. Then he followed the cable movements in real time, guiding the BKK crew until the line’s sag was in the correct position.

“I had never worked like this before, so it was quite cool to watch the lines being adjusted right before my eyes,” said Sellevoll. “And because the SX10 locks onto the line, we only had to aim it once and follow it on the controller. With a traditional total station, we would have had to manually aim the instrument and measure the cable’s position each time it moved. If it had been windy, it would have been much more difficult to do.”

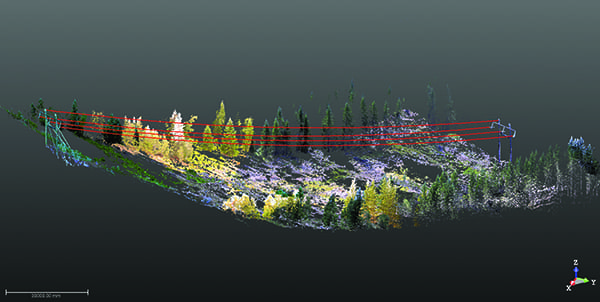

A View to New Business

Although BKK did not require a scan of the power lines, Sellevoll and Vestbø used the opportunity in the field both to test the scanning capabilities of the SX10 and to provide detailed 3-D-derived documentation to their client. Setting up near each utility pole, in a position where the cables were about 18 m directly overhead, they scanned the entire 450-m-long section in two scans, one from the top of the slope and one from the bottom. Collecting 26,600 points per second, each scan took about 10 minutes to complete, acquiring a 3-D scan of all four power lines and two towers in 20 minutes.

“The scanner is surprisingly quick and is quite precise,” said Sellevoll. “It can produce a 360-degree scan directly overhead. And it automatically registers the data so you don’t have to geo-reference the point cloud during post-processing, which is a huge time savings.”

Back in the office, the Geomatikk Survey team used Trimble Business Center software to integrate the point-cloud data and survey data. They then produced a vector-based report, coupled with supporting point-cloud screenshots, to verify that the power lines were adjusted to BKK specifications. That documentation was prepared in one day and delivered to BKK the day after.

“We were very pleased with how smoothly the measurement went and that we could do it in real-time,” said Jan Reime, a project manager with BKK. “An additional bonus for us and our client was the ability to deliver a written report with the actual measurements enclosed.”

“We could not have completed the field work or the project report as well and as quickly as we did with traditional total station technology,” said Sellevel. “The ability to switch between total station surveying and scanning with one instrument allows us to be so much more efficient, both in time and costs. As the scanning gives us the data and detail of an entire project, we can revisit the site virtually as many times as we need without having to leave the office. And with the auto-lock feature of the SX10, we now have the ability to take on projects that require real-time surveying, opening up a whole range of business development opportunities.”

Indeed, based on their debut success in Leikanger, BKK commissioned Geomatikk Survey to return to a different section of the same power line and perform the same sag-measuring work. Colleagues all across Norway have also gotten wind of that project, and they all seem to be curious about the real-time aspect of surveying.

This rising interest could lead to more helicopter rides in Sellevoll’s future. He knows there may be more of the unexpected, but he’s confident he has the right tools to resolve any issues encountered. ■

—Mary Jo Wagner is a Vancouver, British Columbia-based freelance writer with more than 20 years of experience covering geospatial technology.