There are increasing schemes in Europe to use marginally profitable gas-fired power plants to also generate heat for cities, and for good reason. Lausward Power Plant’s Fortuna Unit—POWER’s 2016 Plant of the Year—achieves about 85% efficiency when operated in cogeneration mode while serving Düsseldorf’s district heating. The European Union is making a concerted effort to develop new CHP plants, but there are challenges as green-energy advocates clamor for cleaner alternatives.

An absolutely proven technology worldwide, cogeneration—or combined heat and power (CHP)—schemes are generally fossil fuel, biomass, or nuclear dependent. Plants take the heat that is a byproduct of either combustion or cooling, capture or store it, and then distribute it within a geographical area. Since byproduct heat is generally vented and therefore wasted, advocates of the technology argue CHP provides an elegant solution to an already dirty problem. Accounting for both heat and power generation, plant efficiencies are often 90% and above. However, regulators, investors, and voters continue to clamor for more green solutions.

CHP Snapshot

Throughout the European Union (EU), CHP provides more than 11% of all electricity and 15% of all heat for the 28 member nations. In total, this delivers 15% of the EU’s energy efficiency and 20% of the EU’s climate 2020 objectives, saving Europe about 200 million tonnes of CO2 per year. The contribution of CHP to the energy mix varies greatly among European countries, from less than 5% in Malta, Cyprus, and Greece, to more than 30% in Denmark, Finland, Latvia, Lithuania, and Slovakia. Overall at the European level, cogeneration has remained stable during the past few years.

COGEN Europe, an industry advocacy group, claims CHP installations could provide Europe with up to an additional 120 GW of “cleaner” energy. Yet, it says EU policies and public opinion remain unclear, slowing adoption of what could otherwise be a valuable tool to reduce overall emissions. The group suggests interactions between all energy carriers should be considered and improved, including the flexibility potential provided by heat networks, gas grids, and the transport sector. COGEN is also lobbying to protect existing CHP investments that may be at risk of decommissioning because their primary task—generating electricity—runs counter to CO2 emissions reduction schemes being implemented throughout the EU, and the only way they can reliably make money is by selling heat.

“The big elephant in the energy room is heat. Most political debates about decarbonizing our energy sector focus on decarbonizing our electricity system and electrifying transport,” said Hans Korteweg, managing director of COGEN. However, electricity and transport are just two parts of the system. Heat ultimately accounts for half of all energy consumption by some tallies. Unfortunately, “there is no clear vision, nor strategy on how to decarbonize on a large scale the heat demand in houses and businesses,” continued Korteweg. COGEN argues that CHP is the most-efficient way to produce heat and electricity, offering energy savings ranging between 15% and 40% compared to the separate supply of electricity and heat from conventional power stations and boilers.

Currently bolstered by various funding schemes and emissions credits, Germany, Belgium, Lithuania, and many other nations are moving forward with new CHP projects. Producers are adopting CHP schemes because under EU rules, the captured byproduct—heat—is considered both green and renewable, regardless of what actually generated the heat. These projects then are factored into renewable energy targets, and communities can claim them as green. However, with so much solar and wind—what purists claim are the only “real” renewable energies—now coming online, can CHP projects find a stable space to provide a cleaner baseload power while simultaneously reducing demand for electrically generated heat? And will municipalities accept CHP schemes as a way to reduce carbon emissions going forward?

EU Supports Cleaner, ‘Greener Heat’

There can be little doubt that physically, CHP plants, which combine both the electricity and heat generated, are very efficient in terms of capturing a much larger percentage of a fuel’s energy potential. Further, since the heat is generally used locally, there is less associated line loss from distribution over energy grids.

While far more popular historically for industrial users, many municipalities also rely on a plant’s coincidental heat that is then linked through piping systems around various districts. Thus, in addition to cost savings, cogeneration also yields environmental benefits though using fossil fuels more efficiently. This leads to fewer emissions than the separate generation of electricity and heat.

It helps too that under EU rules, the coincidental heat is also seen as green. “We run a cogeneration plant that also produces carbon-free district heat, which under the law is equivalent to renewable energy,” said Udo Brockmeier, chairman of utility Stadtwerke Düsseldorf in an interview published in Siemens’ in-house magazine. The recipient of POWER magazine’s 2016 Plant of the Year Award mainly because of the efficiency of the Siemens-built natural gas turbines, the Lausward plant’s Fortuna Unit has largely been economically viable because of the heat it has been able to sell to the city—and not just for its electricity.

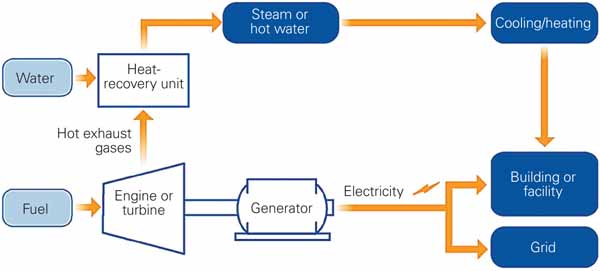

This kind of dual arrangement is nothing new (Figure 1). Coal and gas plants have long been used in CHP schemes. Nuclear plants have as well, particularly in eastern Europe. Increasingly, biomass CHP plants with capacities ranging from a few MW up to 350 MW are also coming online. Small- and medium-sized CHP plants are usually sourced with locally available biomass. Large CHP plants and coal/biomass co-firing power plants require biomass sourced from a wide region or imported wood and forestry residues. Often using pellets from the U.S., many regulators are now questioning the “greenness” of such schemes.

On the EU level, there is an agreed-upon framework for how member states should design support schemes on the national level through the 2012 Energy Efficiency Directive as well as the 2014 State Aid Guidelines for Environmental Protection. Germany is one of the countries that made a high-level political commitment to boosting CHP. Since 2002, the German Combined Heat and Power Act has been the main basis for the promotion of CHP plants.

The act provides a framework for funding based on the application of a surcharge. Pursuant to the CHP act, the operators of funded installations are entitled to the payment of a supplement for a limited period of time. A revision of the CHP act, which entered into force on January 1, 2016, means that government has doubled funding for CHP, raising it to €1.5 billion. The revision focuses on combating climate change by relying more on CHP technology.

Germany, Europe’s largest economy, has set a clear ambition for CHP with a dedicated law and target of 110 TWh of CHP-powered energy by 2020, and 120 TWh by 2025. In May 2017, the federal cabinet adopted a draft ordinance on the introduction of auctions for CHP plants and innovative CHP systems. Through 2021, a total capacity of 200 MW will be auctioned each year, of which initially, 150 MW are to come from conventional CHP plants and 50 MW from innovative CHP systems. In the years that follow, the share of innovative CHP systems will be gradually increased.

In an effort to sweeten the pot, in mid-February the European Commission (EC) ruled in favor of two new “Green Certificate” schemes to support, on a national level, a new CHP plant in Flanders, Belgium. Combined, it will help Belgium meet its 2020 target of producing 13% of its energy needs from renewable sources—a steep climb from the 9% of current capacity in the country.

“Green certificates are one example of national support schemes that correct for unfavorable energy markets or distortions, thus ensuring that cogeneration capacity is rewarded for the benefits it provides to the energy system,” continued COGEN’s Korteweg. “Most EU countries have their own specific support schemes for CHP, with different conditions in place. In some cases, support is insufficient to ensure a growth in CHP or even a stable CHP fleet, but most damaging of all is retroactively withdrawing support, which has happened in Spain for instance.” But policies vary significantly. Going forward, however, other nations will likely also use similar green certificates to access funding.

Barriers and Challenges Ahead

There are many barriers to further CHP adoption. “One is simply the lack of ambition from EU member states to implement existing EU legislation that promotes the use of cogeneration,” said Korteweg, though this could also be read as a lack of desire to invest more in fossil fuels in any way.

Indeed, one of the key criticisms of CHP from renewable advocates is that it simply props up fossil-fueled plants and helps them remain viable as more renewables come online. Without question, CHP has helped Düsseldorf’s city-owned CHP plant remain profitable. This is in direct contrast to several gas plants that had no CHP potential, such as the Uniper-controlled Hartmann plant in Irsching, Germany. Now, after remaining idle for some time, Uniper has petitioned regulators to decommission it despite the plant recently holding world records for efficiency.

While historically the competitive benefits of cogeneration have been widely recognized by a large share of industry, which has invested in CHP to meet energy needs in a reliable and cost-effective way, this was viewed outside the prism of climate change and more as a way to reduce costs.

Revisiting the Plant of the Year

In an interview with Siemens’ The Magazine, Brockmeier defended the city’s adoption of gas-fired CHP, stating that initially planners were “thinking mainly in terms of a product-led rather than a generation-led strategy. In other words, we were asking ourselves what product was relevant for the Düsseldorf market. The answer was heat and power, generated in an environmentally and climate-friendly manner (Figure 2). In retrospect, we still believe it was the right decision, especially when we look at the difficult situation other plants generating only electricity find themselves in,” he said. However, there was also an economic dimension to Düsseldorf’s decision: “the fact that the German government is promoting CHP plants alongside its subsidies for renewables.”

|

| 2. Controlling the operation. The control room of the Lausward heat plant is state-of-the-art, filled with monitors. Courtesy: Stadtwerke Düsseldorf AG |

In the first year of operation, the new gas-fired power plant in combination with the district heating was estimated to have saved 600,000 tonnes of carbon emissions. By 2025, this figure will increase to a million tonnes. Even in 2050, it is expected that about 60% of electricity will come from the CHP plant while 20% will come from wind and solar generation, with the rest from other sources, Brockmeier said.

Nonetheless, he unequivocally acknowledged that despite the turbine’s technological abilities, it’s not electricity that stabilizes the plant, but rather its heat byproduct. “Given the competition from other producers, it’s not always possible to feed electricity into the grid profitably. This is what makes the flexibility of our plant so incredibly important. A gas turbine can be fired up and down very quickly.” However, despite the potential of CHP, Brockmeier highlighted one major point that underscores continuing uncertainty around adoption: “CHP plants only achieve high efficiency if you produce combined heat and power,” he said.

Stadtwerke Düsseldorf is currently building a heat accumulator next to the power plant. “It’ll be 30 meters in diameter and 50 meters high. This will be able to store surplus heat at times when there’s demand for power but not for heat. This substantially increases the time we can cogenerate heat and power. We can release the heat again when the situation reverses,” Brockmeier said in the Siemens interview.

CHP Projects Abound in Europe

Throughout Europe, there are several high-profile CHP projects that have recently come online, are under construction, or have been green-lighted. One of the largest is the new municipal cogeneration project underway in the port city of Kiel, about 90 kilometers north of Hamburg, Germany.

Unveiled in August 2015, Stadtwerke Kiel is constructing a new natural gas-fired CHP facility (Figure 3) to replace an existing coal-fired community power plant. By cogenerating in such a manner, Kiel is “truly killing two flies with one swatter,” as they say in German. By replacing coal with natural gas, the city will immediately achieve a CO2 reduction, combined with capturing and distributing the heat byproduct, and the city will achieve even greater greenhouse gas savings.

According to COGEN, the new CHP plant comprised of 20 gas engines is expected to reduce CO2 emissions from 1.8 million tons to approximately 540,000 tons. The total efficiency of the GE J920 gas engines are greater than 90% (electrical efficiency is 45%). Serving 70,000 Kiel households, the new GHKW cogeneration facility represents a total investment of about €290 million and is the largest investment in the history of Stadtwerke Kiel. Utilizing a heat storage accumulator, this CHP facility is also unusual because it relies on the aforementioned fleet of engines to ramp up and down quickly and thus maintain a high efficiency.

In mid-January, the EC adopted two funding decisions to support the construction of a CHP plant in Vilnius, Lithuania, designed to produce electricity and heat from biomass and municipal waste. More than €139 million from the EC Cohesion Fund was invested in the plant, in addition to a €190 million European Investment Bank loan backed by the European Fund for Strategic Investments, the heart of the Investment Plan for Europe.

The state-owned utility Lietuvos Energija has already begun work on the €350 million project, which is expected to supply 87.6 MWe and 227 MWth. About 18 MWe and 53 MWth are planned to come from waste-to-energy systems. Commissioning is planned for late 2019. The project is reportedly Lithuania’s largest energy project to date. Simultaneously, Lietuvos Energija and Finland’s Fortum are also building a 24 MWe/70 MWth CHP plant in the city of Kaunas, at an estimated cost of approximately €150 million.

State-owned Fortum, looking to acquire even more stable CHP facilities, just closed a multi-billion Euro deal in February to acquire the mostly-fossil-fueled assets of Germany’s Uniper. Formerly owned by E.ON, one of the largest investor-owned utilities in the world, the parent company had bundled most of its older fossil-fueled assets into Uniper to concentrate on renewables. Fortum publicly announced it was seeking to acquire CHP plants and found Uniper’s plants attractive because a large number of those old coal-fired power plants, many of which are located within the Ruhr Valley—Germany’s historic industrial heart—are tied into district heating systems.

Vattenfall’s CEO Magnus Hall also recently requested that the new German government provide a clear date to shift away from coal while continuing to provide incentives to maintain and expand CHP. Vattenfall, completely owned by the Swedish state, recently sold off its lignite mines in Germany along with the associated power plants but retained several more-advanced hard coal-fired plants in both Berlin and Hamburg. Owner of several of the newest coal-fired plants in Europe, including the 1,650-MW Moorburg CHP-capable plant in Hamburg, Vattenfall’s reduced fleet in Germany consists of only CHP or CHP-capable plants.

But in a 2013 referendum, Hamburg’s voters decided to remunicipalize the city’s power, gas, and heating systems and supplies that are currently majority-owned by Vattenfall. Following the vote, Hamburg and Vattenfall signed a contract that allowed the city to buy out the company’s nearly 75% share by 2019, but as of mid-February both parties remain deadlocked over the price (between €950 million and €1.3 billion).

One aspect of the dispute is the suspension of the nearby Wedel CHP project. In 2016, Vattenfall announced plans to invest €83.5 million to refurbish the 260-MWe/433-MWth hard coal-fired CHP plant in order to “secure Hamburg’s district heating supply for the next couple of years” in the face of more stringent environmental standards. At the time, Reuters reported that the company was also “developing a concept to achieve climate neutrality in Hamburg heat operations by 2050,” which could potentially include “heat storage, power-to-heat, industrial heat, decentralized solutions and possibly gas-CHP that will replace the existing plant.”

However, in 2017, a local environmental consultancy group won the backing of many citizens when it proposed an underground facility designed to store excess heat from industry and power generation, supplying about a quarter of the city’s heat demand and thereby rendering Vattenfall’s scheme unnecessary. The final decision is in the hands of an independent arbitrator, who will make an announcement in April. It suffices to say Hamburg’s voters are looking intensely at getting away from coal as soon as possible.

With that in mind, there were muted celebrations in early February when, with GE’s help, the city commissioned a new 8.4-MWe CHP plant that will supply power for up to 20,000 households as well as heating and hot water for 500 businesses and residential buildings. Operated by HanseWerk Natur, it utilizes GE Jenbacher engines (Figure 4) and replaces heat generation from a landfill plant. Owned by the newer version of E.ON, the CHP plant can achieve a total efficiency greater than 95% when taking into consideration both heat and power generation. Emissions are also expected to be 40% lower than conventional coal-fired plants, satisfying the concerns of local green energy advocates. ■

—Lee Buchsbaum (www.lmbphotography.com), a former editor and contributor to Coal Age, Mining, and EnergyBiz, has covered coal and other industrial subjects for nearly 20 years and is a seasoned industrial photographer.

Opening image courtesy: Stadtwerke Düsseldorf AG