Future propulsion and energy systems must be designed to meet the social challenges of climate change, increased energy requirements, and the mobility and energy demands of a growing world population. Fuel cells could be a vital piece of that puzzle.

The potential of fuel cell technology is convincing, as is hydrogen as a storage medium within an overall energy system. Strong arguments for using and promoting this technology are high reliability, scalability, and the ability to use renewable energy sources.

With their modular design, fuel cell systems are easily adaptable to match output with demand, and their low maintenance requirements and low running costs also make them attractive. Furthermore, fuel cell technology is ready to be brought to market and suitable for commercial use. The rapidly developing market offers good growth opportunities for zero-emissions fuel cell technology.

How Fuel Cells Work

Fuel cells work differently compared to combustion engines. They convert a fuel’s chemical energy directly into electricity, which can then be used to drive a growing number of electrified systems. This conversion is more efficient than with combustion engines, as the intermediate thermo-mechanical steps required with conventional energy converters (heat engines) are eliminated.

The greatest plus point arises when the fuel used is regeneratively produced hydrogen because it allows both pollutant and climate-damaging gas emissions to be reduced to zero. In this way, fuel cells have an enormous potential to become an essential technology component for decarbonizing propulsion and energy systems.

The low-temperature proton exchange membrane fuel cell, or PEM (sometimes called polymer electrolyte membrane fuel cell), currently represents the most suitable technology for developing and growing the Rolls-Royce Power Systems portfolio. This low-temperature fuel cell has a high power density enabling even small units to achieve sizeable outputs.

Low-temperature fuel cells have operating temperatures of up to about 100C, posing minimal hazards to both materials and people, while high-temperature fuel cells reach 250C to 1,000C. The PEM has good load-following characteristics as opposed to other types, allowing it to respond to changes of power requirement within seconds.

One advantage of the compact PEM fuel cell is its very high electrical efficiency, especially at part load. They typically run on a hydrogen fuel source; however, they can operate on a wide variety of hydrocarbon fuels (such as methanol, diesel, or natural gas). This is achieved by using well-known reforming techniques to convert the fuels into hydrogen. This gives PEM fuel cells a very wide-ranging field of applications.

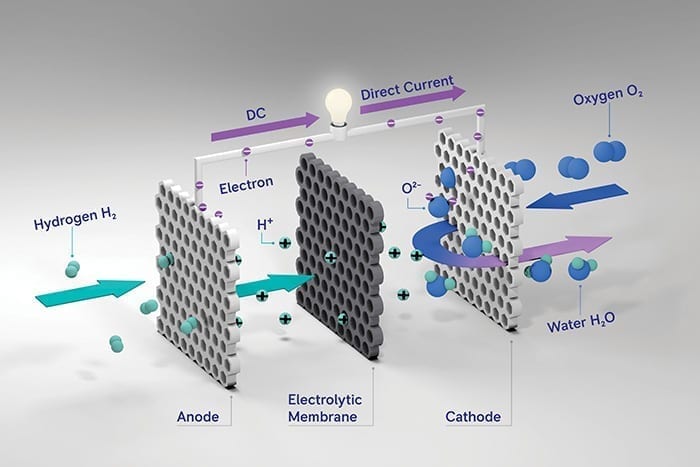

The PEM fuel cell is a galvanic cell that electrochemically reacts fuel and an oxidant (usually air) to produce electricity and exhaust products (Figure 1). It works quietly and without much in the way of vibration. Similar to batteries, fuel cells also generate direct-current voltage. However, unlike batteries, fuel cells require a constant inflow of fuel and oxidant.

|

|

1. Proton exchange membrane fuel cells include an anode, cathode, and electrolytic membrane. Courtesy: Rolls-Royce Power Systems |

With a PEM fuel cell, a chemical process takes place between the electrodes (anode and cathode) in which the positive ions (protons) migrate from the anode to the cathode, and the electrons are conducted externally from the anode to the cathode via an electrical conductor. The product of this process is electrical power that can be withdrawn and used. The electrodes are coated with a platinum or palladium catalyst and separated from each other by an electrolyte. Without the catalyst, hydrogen and oxygen would not react to produce heat and electricity. The electrolyte consists of an ion-conducting membrane, and it is important for this membrane to be permeable for protons and impermeable to electrons.

Improving Upon Well-Established Technology

The name “polymer electrolyte membrane fuel cell” indicates that the membrane is a key feature of this fuel cell. This is usually made of plastic and is similar to Teflon. The water-saturated polymer membrane, which serves as an electrolyte, allows only protons—the positively charged atomic nucleus of hydrogen—to pass from anode to cathode. The water content of the membrane required for this ion conduction is responsible for limiting the operating temperature to a maximum of 100C. The amount of precious metal (such as platinum) required for the catalyst has been steadily reduced in recent years. This has already led to a significant reduction in costs and remains the focus of development efforts.

For Rolls-Royce Power Systems applications, the PEM fuel cell is ideal thanks to the high power density, high scalability, modular design capability, and resultant flexibility. Fuel cells can, for example, be built directly into battery-powered or electrified energy systems. The cell achieves high electrical efficiency (about 50%) and high current density, and is also very safe to use. This makes it suitable not just as a source for stationary power—say in the form of an emergency generator or an uninterruptible power supply—but also ticks all the boxes for mobile use aboard ships.

In order to increase the power density even further, today’s fuel cell systems sometimes feature air compressors or even electric turbochargers. As with internal combustion engines, the compressors or turbochargers pump air into the air system at a pressure of 2 bar to 3 bar. Several individual fuel cells can be connected in series to form a stack, thus increasing the voltage. To achieve more performance, the stacks can also be connected in parallel. This increases the amount of current generated to multiples of that achieved by serial connection.

In developing and applying fuel cell technology, Rolls-Royce Power Systems draws on in-depth expertise and years of experience (Figure 2). Between 1999 and 2011, 26 high-temperature fuel cell systems—molten carbonate fuel cells (MCFCs)—were installed and successfully operated in various areas of application. The combination of electricity and pressurized steam is used in a wide range of processes in industry and in the health sector. The systems have run an average of about 22,000 operating hours, and all performance data and empirical values have been recorded and analyzed. While market conditions and the general framework at that time did not support full production, all lights are now green for introducing PEM fuel cells into mass-market settings as an alternative source of drive power.

|

|

2. A pilot fuel cell project is shown here. Fuel cell systems can be easily scaled up by adding more modules. Courtesy: Rolls-Royce Power Systems |

Fuel Cell Applications

Their characteristic features mean PEM fuel cells are suited to various applications currently powered by combustion engines. Among other things, fuel cells could play a key role in zero-carbon data center, demand response, and marine propulsion systems.

Data Centers. Data centers are part of safety-critical infrastructure worldwide, including in hospitals, airports, and telecommunications centers. Many data centers use diesel gensets for emergency power. The combustion of fossil fuel (diesel) inevitably results in exhaust gas emissions. If fuel cells were used for the backup power supply, the only things given off are heat and humid spent air. The fuel cell system has no moving parts, which minimizes mechanical maintenance. Fuel cells are also more efficient than engine-based backup systems. A further advantage is that fuel cell systems can be scaled with ease. More modules mean more power, and fuel cell systems can easily be added later and grow with the data center.

Demand Response. A high degree of flexibility is required for the increasing use of renewable energy sources. When surplus wind or solar power exists, rather than curtailing production, the electricity could be used to produce hydrogen through electrolysis, which could be stored. When needed, this energy could be made available again at short notice in the form of electricity with the aid of a fuel cell system. This load management or “demand response” activity using smart grids could be one of the key factors for converting energy systems to sustainable methods of production.

A demand response solution using PEM fuel cells in combination with batteries is ideal for stabilizing grids and cushioning power peaks. Consumers can use the system to cover their requirements even when generation output from renewables is low. The PEM fuel cell generator offers the ability to be connected to locally operating systems or to microgrids.

Marine Propulsion. Alternative propulsion systems are attractive and necessary not just for cars and trucks, but also for ships. Shipping accounts for 2% to 3% of global CO2 emissions, and this proportion is set to rise significantly by 2050 with the increase in global trade. Onboard fuel cell systems combine numerous benefits. In addition to their sustainability and environmental friendliness, fuel-cell-based marine propulsion systems are gaining favor due to their high level of passenger comfort and high modularity. They are quiet, they produce no smelly exhaust gases, and they are virtually vibration-free. This emission-free propulsion system enables vessels to be used in sea, lake, and river areas, where some other systems are frowned upon due to adverse environmental impacts.

A fuel cell marine propulsion system is made up of several parts. At the heart of the system is the fuel cell, which converts hydrogen into electricity. This power is fed via the onboard electrical distribution system to large consumers, such as the electric motors driving propellers and winches, and also to the smaller “domestic” consumers. The onboard distribution system also features a power storage device, typically a lithium-ion battery, to store power temporarily. This battery permits a time lag between generation and consumption of power, thus opening up the possibility of timing the operation of individual components for maximum efficiency. This calls for a smart power management system for controlling individual components.

Fuel Cell Outlook

Fuel cell technology is increasingly gaining traction in view of pollutant emissions and climate protection requirements. When it comes to making the best use of renewables for low-emission, zero-carbon production of electricity and heat, the fuel cell is the front-runner in terms of efficiency compared with other systems, making it an attractive proposition for a variety of applications. Even today, fuel cells can be used to ensure efficient energy supply within stationary standalone facilities, as well as their mobile use powering land vehicles and ships. The big advantage of hydrogen-powered fuel cells is that CO2 emissions, whether from vessels or stationary power plants, reduce to zero where green hydrogen is used.

—Michele Bozzolo, Georg Fink, and Benjamin Oszfolk are fuel cell system engineers, and Philippe Gorse, PhD is head of Fuel Cell Technologies, all with the Power Systems division of Rolls-Royce.