Boiler slagging and fouling, and the resulting frequent operation of sootblowers, are some of the major operations and maintenance factors that can negatively affect power plant reliability and efficiency.

Boiler slagging and fouling are among the most common causes of maintenance headaches at coal-fired power plants. Though you cannot totally eliminate the problem, following proper operation and maintenance practices can drastically reduce the time and trouble of addressing it.

Demystifying Slagging and Fouling

Let’s review what slagging is before getting into the causes and corrections of slagging and fouling.

Slag is molten ash and incombustible byproducts that remain following coal combustion. When the material cools to a certain temperature, it can stick to furnace components, such as waterwalls, which is called slagging.

A pulverized coal–fueled boiler is designed with a large furnace cavity that can tolerate liquid phase slag on the waterwalls. The furnace exit, however, should be at a low enough temperature that the slag will be cooled below its softening temperature.

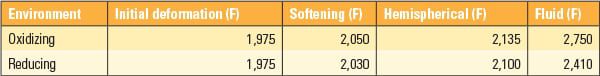

A typical bituminous fuel ash fusion temperature is determined using the American Society for Testing and Materials (ASTM) standard D1857. To conduct the test, a cone of ash is placed into a laboratory furnace and the furnace is slowly heated. The furnace temperature is noted at four points as the ash cone deforms.

The temperature of the first point—when the ash cone point becomes blunted—is called the “initial deformation temperature.” As the furnace is heated more, the temperature when the ash becomes soft and the height (H) of the cone equals the width (W), is recorded. This value is referred to as the “softening temperature.” Heating continues, resulting in the ash cone sagging further until H = 1/2 W. This temperature is called the “hemispherical temperature.” Finally, when the ash cone becomes a liquid, the temperature is noted and referred to as the ash “fluid temperature.”

Modern laboratories use more advanced furnaces than when the method was first developed, but the reporting of the ash fusion temperatures is still completed using the same four levels of ash fusion: initial deformation, softening, hemispherical, and fluid.

The purpose of the laboratory test is to determine the approximate condition of the ash when it is in various parts of a boiler furnace. For slagging and fouling, the most important issue is to have the furnace gases or “products of combustion” leaving the furnace at a temperature so that the ash is not too sticky. A good approximation is to have the furnace exit gases about 100F to 150F cooler than the ash softening temperature.

I have seen furnaces where the furnace exit gases are above the fluid temperature, and it is possible to operate a boiler with liquid-phase ash flowing through the superheater and reheater, but it is not advisable for reasons of coal ash corrosion and the need for near-continuous long retractable sootblowing to mitigate the ash deposits.

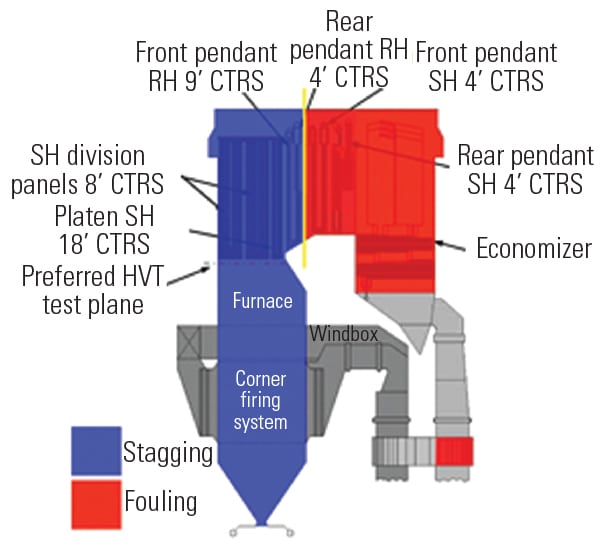

“Fouling” typically refers to deposits that occur in the convection pass after the gases exit the furnace. Fouling is generally attributed to ash cinders and accumulations that form on the leading edges of the superheater and reheater tubes (Figure 1), especially the outlet legs, which are above 1,000F metal surface temperature. The deposits are dislodged by sootblowing.

When the long retractable sootblowers are used to blow the ash deposits free, the ash particles entrain into the flue gas stream and create cinders, which can block selective catalytic reduction (SCR) catalyst flow paths, plug air heater baskets, and bridge across boiler tubing in the convection pass. Usually, the areas of the boiler that are designated as being susceptible to slagging are from the burner belt to the furnace exit.

Heat flows from hottest to coolest and, therefore, to produce 1,000F to 1,100F superheated steam and reheated steam outlets, the furnace exit gas temperature (FEGT) must be above about 1,500F at the reheater gas inlet to drive the heat flow into the reheater and superheater to create the desired steam temperatures. Consequently, the sweet spot for the FEGT of a pulverized coal–fueled boiler should be about 2,150F to 2,250F to achieve desired steam temperatures without slagging. Lower than 2,150F it becomes difficult to achieve design steam temperatures. Above 2,250F on a bulk gas basis, it becomes close to the melting temperature of the ash in some fuels.

Fuels with extremely high ash fusion temperatures are thought of as being “boiler friendly” and forgiving. Fuels with lower ash fusion temperatures require more precise combustion tuning and increased sootblowing to mitigate slag deposits.

Let’s take a look at the coal ash fusion D1857 analysis shown in Table 1 as an example. Given the ASTM D1857 temperatures of the ash fusion analysis, the ash condition can be estimated in the furnace and at the furnace exit, if the temperatures are known.

|

| Table 1. Ash fusion analysis example. Source: Storm Technologies Inc. |

In this example, the coal ash analysis shows a fluid temperature in a “reducing atmosphere” of 2,410F. So, if there are lanes of products of combustion that are fuel rich and still actively burning, then this is in fact a “reducing atmosphere” for the particular lane of fuel-rich products of combustion. In practice, this could result from one burner that is fuel heavy and air lean. The products of combustion from that one burner can, in fact, slag up the furnace exit.

Some fuels are more unforgiving than others. The coal ash iron content is a huge factor. Ash that has as much as 15% to 20% iron content will have an ash fluid temperature in a reducing atmosphere as much as 500F lower than the same ash in an oxidizing atmosphere. Current plant operations with a strong regulatory limit on NOx tend to drive operators to operate at low excess oxygen levels. This practice, combined with fuel and air imbalances, can result in conditions in which flue gas lanes can have zero free oxygen and, therefore, are technically operating in a reducing atmosphere.

So, how can a reducing atmosphere or secondary combustion be created at the furnace exit? Here are six of the most common causes of boiler slagging and fouling in our experience:

■ Low furnace excess oxygen

■ Extreme stratifications of the FEGT flue gas lanes

■ High primary airflows

■ Burner damage and deficient mechanical condition/tolerances

■ Poor coal pulverizer performance

■ Inconsistent fuel properties and chemistry

Low Furnace Excess Oxygen

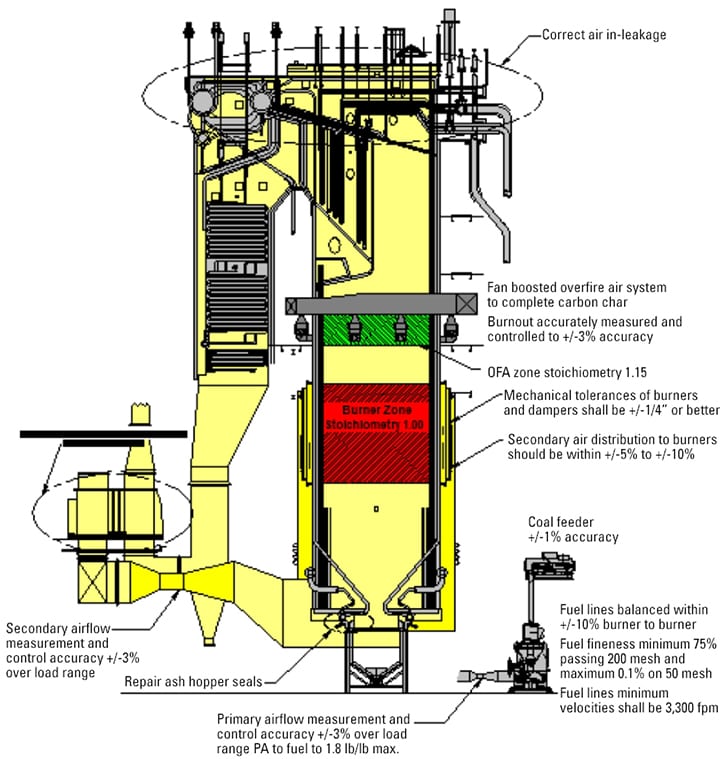

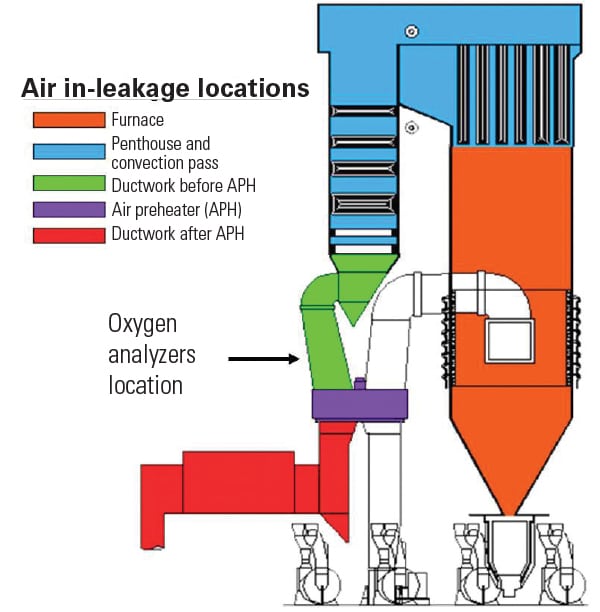

The No. 1 cause of furnace slagging is low furnace oxygen content. Most boilers are designed for 115% to 120% theoretical combustion air. This is generally expressed as 15% to 20% excess air. For coal furnaces, the oxygen levels would be 3% to 3.8%. Note the location of the oxygen analyzers at the economizer exit in Figure 2. This location is often subject to reading higher oxygen levels than the actual furnace oxygen content, due to air in-leakage between the furnace and the air heater flue gas inlet.

|

| 2. Location, location, location. Furnace oxygen content instrument readings can be inaccurate due to the location of the analyzers. Source: Storm Technologies Inc. |

It is extremely important to apply the attention necessary to optimize the furnace burner belt “inputs,” because combustion must be completed within the furnace cavity. Of absolute importance is providing sufficient combustion airflow to the fuel before the products of combustion exit the furnace. One of the most common causes of slagging and fouling is secondary combustion at the upper furnace. The most common cause of secondary combustion is insufficient excess oxygen within the burner belt.

Why is this so common? There are two reasons. First, most U.S. boilers have some age on them, and the boiler settings have allowed air in-leakage to increase over the years. Because the oxygen analyzers are usually located at the economizer outlet, the excess oxygen that is measured at the economizer exit includes any ambient air that has leaked into the boiler setting after combustion should have been completed. This lack of excess free oxygen at the furnace causes the active combustion to stretch out and actively continue into the superheater section. The flue gas temperature, due to such secondary combustion, can and has been measured to be well over 1,000F above optimum.

The second factor is that when the coal ash has an iron content of over about 10%, the melting temperature of the ash is lower in a reducing atmosphere. In other words, not only does the secondary combustion elevate the FEGT, but also, if the coal ash contains significant amounts of iron, the fusion temperature can be drastically lower as a result of the ash chemistry. That is, the ash will melt at a much lower temperature in a reducing atmosphere from what the fusion temperature would be in an oxidizing atmosphere. As noted previously, the ash fusion temperature can be reduced by as much as 500F.

These two factors combined are particularly serious for eastern U.S. plants that burn bituminous fuels. The iron content in the ash has not been a large factor with Powder River Basin fuels, but secondary combustion affects all boilers and all fuels.

Extreme Stratifications of the FEGT Flue Gas Lanes

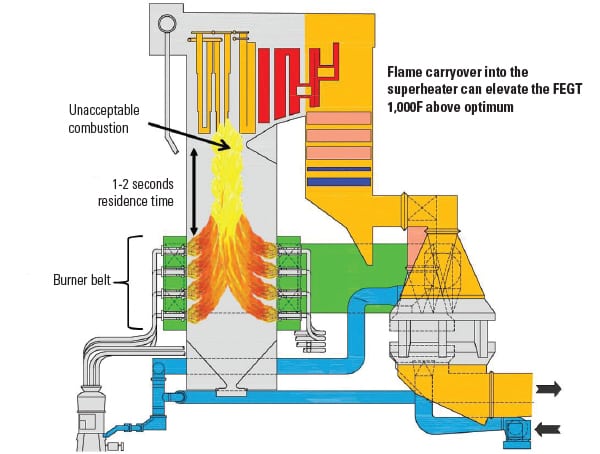

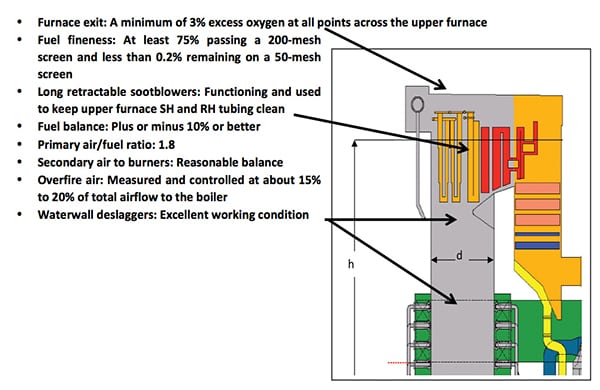

The limited residence time of large utility boilers demands that the furnace inputs of fuel and air be optimized (Figure 3). If not properly controlled, fuel/air inconsistencies can contribute to slagging and fouling issues due to secondary combustion and elevated FEGTs. Optimizing the fuel and air inputs to the furnace and making certain that the furnace exit is an oxidizing atmosphere are the first steps in reducing furnace slagging.

Fuel input optimization includes ensuring that:

■ Coal fineness meets the following guidelines: At least 75% passes a 200-mesh screen and less than 0.2% remains on a 50-mesh screen with representative and isokinetically removed coal fineness samples.

■ Coal distribution to each burner must be balanced plus or minus 10%.

Combustion air optimization includes ensuring that:

■ Primary airflow quantities are optimized and air/fuel ratios are repeatable.

■ Measured and controlled secondary airflow is uniformly distributed to the individual burners.

■ Measured and controlled overfire airflow is optimized.

FEGT and excess oxygen can be measured with a water-cooled high-velocity thermocouple (HVT) probe. The measurements by HVT probe should be a minimum of 3% excess oxygen with maximum temperatures about 100F to 150F below the ash fusion temperature. It is when the FEGT approaches the ash fusion temperature that slagging occurs.

Often, the most useful data obtained by using a water-cooled HVT probe is the furnace exit, excess oxygen levels, and profiles. All points at the upper furnace should be oxidizing and preferably above 3% excess oxygen.

The word “slagging” is usually used to describe slagging in the furnace, whereas fouling is generally used to describe cinders or ash that have carried over into the convection pass and created flow obstructions due to the deposition. As discussed previously, fouling of the convection pass, SCR, and air heater are the result of ash accumulations on the leading edges of superheater and reheater tubing that is removed by long retractable sootblower operation.

Minimizing slagging and fouling begins by optimizing the burner belt combustion performance. This is necessary because there is only about 1 or 2 seconds of residence time between the top of the burner belt and the superheater flue gas inlet. At the furnace exit, the superheater and reheater tube spacing becomes closer and closer, resulting in narrowing gas flow lanes.

The typical FEGT is about 2,150F to 2,250F, assuming that the prerequisites for optimum burner belt combustion are present for the inputs. In the superheater shown in Figure 4, the peak furnace flue gas temperatures were well above the melting temperature of Alloy 310 stainless steel (about 2,780F). The active secondary combustion peak temperatures were truly about 1,000F above the FEGT with optimized burner belt inputs. When optimized, the FEGT was a uniform 1,950F to 2,100F across the boiler width. Prior to optimization, temperatures of 2,850F to 3,100F were present. These extremes have been documented in numerous cases.

|

| 4. A bridge to nowhere. This superheater was slagged over because the furnace exit gas temperature was about 1,000F above optimum. Courtesy: Storm Technologies Inc. |

The cause of the high temperature in this case was threefold. First, primary air velocities were high, which drove the fuel deep into the furnace, away from the secondary air provided at the burners. Second, the burner belt suffered from combustion air starvation due to the overfire airflow being too high and exceeding 20% of total airflow, with only about 115% of total theoretical airflow to the boiler. In other words, the burner belt was deeply staged at sub-stoichiometric excess oxygen levels. Third, fuel fineness and distribution was not optimized. The flue gas temperatures were over 3,000F at the superheater gas side inlet. At this temperature, the ash condition was fluid, and it only took a couple of shifts to completely slag the furnace exit.

It is common to find between 0.5% and 1% oxygen rise from the furnace to the air heater inlet flue gas. Why? Well, for one reason, the average 500-MW pulverized coal–fueled boiler is more than 30 years old. Therefore, the potential for air infiltration is increased due to age alone, even when diligent and thorough maintenance repairs are practiced. The only excess oxygen that matters from a slagging and fouling viewpoint is the excess oxygen present at the furnace exit. Keep in mind that the available residence time from the top to the burner belt may be less than 1.5 seconds.

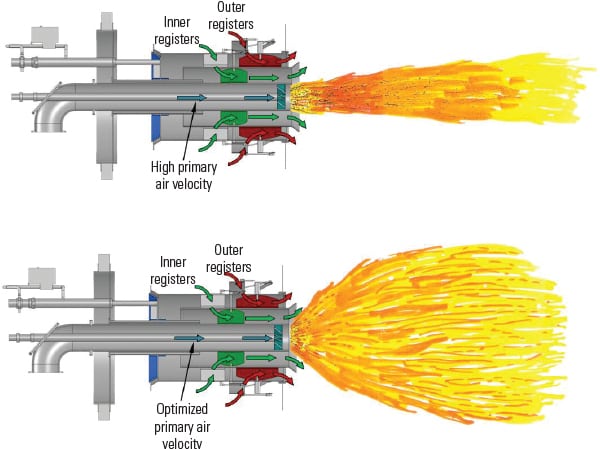

High Primary Airflows

High primary airflow, especially on wall-fired boilers, contributes to poor fuel balance, poor fuel fineness, and longer flame lengths. Primary air is basically transport air and provides 15% to 25% of the total air for combustion. Therefore, when the primary airflow is very high, the fuel particles “outrun” the secondary air and result in longer-than-optimum flames (Figure 5).

|

| 5. Don’t out-kick your coverage. When primary airflow is too high, fuel gets driven deep into the furnace. Source: Storm Technologies Inc. |

High primary airflow on nearly any modern low-NOx burner will drive the fuel deep into the furnace, thus outrunning the secondary airflow. As a consequence, fuel-rich zones can form in the upper furnace, resulting in secondary combustion, elevated temperatures, and zones of localized reducing atmosphere—all of which contribute to slagging and fouling.

Burner Damage and Deficient Mechanical Condition/Tolerances

One of the 13 essentials of optimum combustion is burner tolerance at plus or minus one-quarter inch. The photographs shown in Figure 6 offer some examples of typical as-found burners.

|

| 6. Out-of-spec. Damaged burners must be repaired in order to optimize combustion. Courtesy: Storm Technologies Inc. |

Most of the damage to burners results from overheating of idle burners due to radiant furnace heat. One way to monitor for burner overheating is to attach thermocouples to the burner nozzles and provide cooling air through the burner nozzles to keep below 800F when out of service. (Burner cooling is a topic for another day.)

Poor Coal Pulverizer Performance

The most frequent cause of extreme fuel imbalances at the furnace exit is coal pulverizer performance. Poor fuel fineness nearly always contributes to poor fuel balance. At best, pulverized fuel balance will be in the range of plus or minus 5% to 15% deviation.

When classifiers are not set for best fineness (usually to substitute more coal pulverizer throughput for reduced fineness), the fineness may deteriorate to less than 70% passing 200 mesh. Along with the reduced fineness, there will be less-uniform fuel balance. Poor fuel fineness nearly always results in poor fuel distribution. It is not unusual to find fuel deviations of plus or minus 25% when the pulverizers are not optimized.

The coal pulverizers are the heart of a pulverized coal–fueled boiler. About 75% of the opportunities for improvements in tuning are with the coal mills, primary airflow, and fuel line balancing. Figure 7 shows the important points for achieving optimum combustion with minimum slagging and fouling.

|

| 7. Optimization overview. Getting these parameters in sync is a good start to optimizing combustion and minimizing slagging and fouling. Courtesy: Storm Technologies Inc. |

For additional articles on related topics—from fuel analysis to pulverizer control—search powermag.com. ■

—Richard F. (Dick) Storm, PE is senior consultant for Storm Technologies Inc. and a long-time POWER contributor. The staff of Storm Technologies contributed to this article.