Dr. Michael Weinhold, chief technology officer of Siemens Energy, discusses the company’s 2011 business plans and the role of the smart grid in the future’s energy infrastructure.

Siemens Energy calls itself the “only supplier worldwide with comprehensive know-how encompassing the entire energy conversion chain.”

Peltier: What innovations in the company’s 2011 product line should we expect?

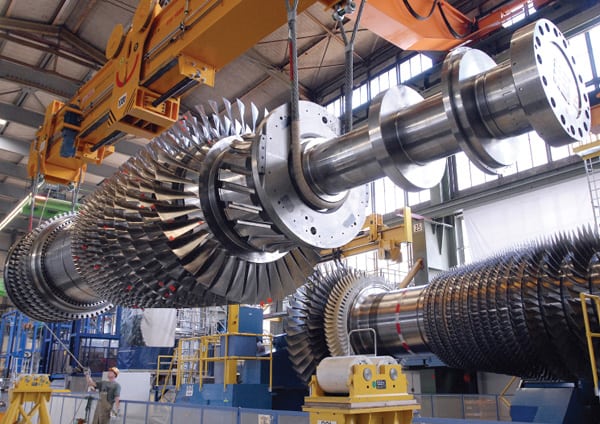

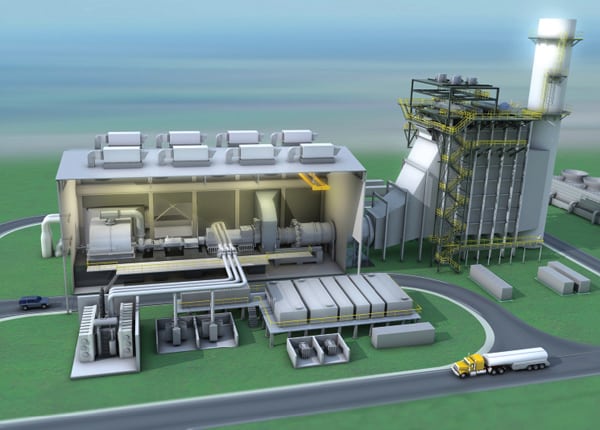

Weinhold: Expect to see a number of milestone products in 2011. For example, the Siemens Energy Sector (Siemens) will commission the Irsching 4 combined-cycle power plant, located near Ingolstadt, Germany, based on the world’s most powerful gas turbine, the 375-MW SGT5-8000H. The plant will have an industry-leading efficiency of more than 60% while producing 570 MW. Siemens has also entered the U.S. market with the new generation of energy-efficient H-class gas turbines. Starting in 2012, six of the turbines will be in operation for Florida Power & Light for the modernization of its Riviera Beach and Cape Canaveral Next Generation Clean Energy Centers. Each plant will feature three 274-MW SGT6-8000H gas turbines. Providing much-improved operating flexibility, this combustion turbine can go from standby to start-up in 5 minutes and reach full power operation in only 15 minutes.

We also received our first order for a “Flex-Plant” combined-cycle plant from Northern California Power Agency. The 280-MW power plant will be located in Lodi, California. The concept of a flexible design is unique because of its fast-start capability: The plant is designed to deliver approximately 200 MW to the grid within only 30 minutes, several times a day. These short start-up times also reduce plant emissions.

We also just launched a new combustion turbine—the SGT-750—in November 2010, a perfect addition to our combustion turbine portfolio. With an output of 37 MW, the SGT-750 will fulfill an increasing market demand for industrial applications.

Siemens will also supply gas turbine packages to a coal-fired integrated gasification combined-cycle plant that will be located in Liberty, Mississippi. Tenaska, one of the largest U.S. independent power producers, chose Siemens to provide the coal gasification technology for its Taylorville Energy Center. With a gross capacity of 730 MW, the advanced clean coal generating plant will be one of the first commercial-scale coal gasification plants with carbon capture and storage capability in the U.S.

Siemens’ wind business is on track to become one of the world’s top three suppliers of wind turbines by 2012, is already one of the top three in the U.S., and is already ranked number one in offshore wind. For example, Siemens has signed an agreement with Cape Wind for the supply of 130 3.6-MW offshore wind turbines for the first offshore wind farm in the U.S. Cape Wind will be located on Horseshoe Shoal in Nantucket Sound off Cape Cod in Massachusetts.

Siemens’ wind power portfolio includes a range of high-efficiency wind turbines suited for onshore and offshore applications. Two examples: The SWT-3.0-101 wind turbine with a 3-MW power capacity has a rotor diameter of 101 meters and offers an innovative direct drive concept using a permanent magnet generator. Compared to a standard wind turbine with gearboxes, Siemens was able to reduce the number of parts in the turbine by half. With fewer moving parts, the direct drive technology has the potential to significantly reduce maintenance time, increase turbine availability, and be positioned both on- and off-shore. The first three machines, sold to Oklahoma Gas & Electric as part of their 227-MW Crossroads wind power plant, are scheduled for delivery in April. On the second project, Siemens teamed with Statoil to develop a floating wind turbine—Hywind—designed for installation in water depths between 120 and 700 meters.

Siemens is deeply committed to developing the wind business in North America, as shown by our construction of a new production facility in Hutchinson, Kansas, that started producing nacelles in December 2010. We also recently expanded our blade manufacturing facilities in Fort Madison, Iowa, and announced last August that Siemens will construct a blade manufacturing facility in Canada.

Siemens has also heavily invested in the two solar technologies: photovoltaics and solar thermal power plants. Siemens is the clear market leader for steam turbines for parabolic trough power plants—a key component for solar thermal power plants. The demands on the steam turbine are unique, as it must be able to start up quickly when the sun rises in the morning and flexibly adapt to the variable thermal input during the day. Siemens has decisively strengthened its portfolio in the field of concentrated solar power plants with the acquisition of Solel Solar. Today, Siemens is the only company capable of supplying two-thirds of a solar thermal power plant from a single source.

Siemens is optimizing efficiency along the whole energy chain, including power plants with an outstanding efficiency factor; long-distance, low-loss, high-voltage direct current transmission systems; more-efficient methods of electric power distribution in cities; and highly sophisticated energy management systems for buildings. Siemens has also promised to invest up to around €100 million through the end of 2012 to make its factories greener and is working with over one thousand of its suppliers to improve their environmental and energy-efficiency records.

Peltier: The global economic and financial crisis that reduced power demand and tightened credit caused markets for large power generation equipment to hit rock bottom. How did your company fare?

Weinhold: Despite the economic crisis, the Siemens Energy Sector achieved record results in the past fiscal year. In fiscal 2010 (ended September 30), the Energy Sector had revenues of approximately €25.8 billion and received new orders totaling more than €30.1 billion and posted a profit of more than €3.5 billion. On September 30, 2010, the Energy Sector had a workforce of more than 88,000.

Peltier: What is your company’s perspective on the China and India markets?

Weinhold: Emerging markets, with a focus on BRIC (Brazil, Russia, India, and China) countries and the Middle East, are key growth areas for Siemens. For instance, BRIC/ME will produce up to one-half of the worldwide gross domestic product growth during the period of 2008–2014.

We expect strong growth in these emerging markets with SMART products and solutions that are simple, maintenance-friendly, affordable, reliable, and timely-to-market. That is why Siemens increases the local value added and responsibility for developing and producing SMART products in these emerging markets. SMART helps to maintain and to further increase our market share in these markets and helps defend our competitiveness against low-cost competitors.

Peltier: What are some major barriers of doing business with governments or private entities in developing countries, and how do you deal with them?

Weinhold: Our approach is to think global and act local. In this respect we engage with private entities in developing countries, for example, via the development of joint ventures to increase our market share. In China, Siemens recently increased its ownership share in Shanghai Electric Power Generation Equipment Co., Ltd. from 33.7% to 40%. The joint venture provides power generation products and solutions for coal-fired and gas-fired power plants as well as for the conventional part of nuclear power plants. Siemens and Shanghai Electric also intend to set up a new service joint venture for the rapidly growing Chinese steam and gas turbine power plant market. Siemens Energy maintains 24 operating companies in China; eight are operated as a joint venture with Shanghai Electric.

Siemens is also committed to energy efficiency and is committed to applying its extensive power technologies to help Chinese customers improve their energy performance while lowering their environmental impact.

Peltier: What is your involvement in smart grid technology development?

Weinhold: Siemens has been working for decades to meet the complex challenges posed by smart grids as part of an efficient and sustainable energy supply. Our interests include virtual power plants, island grids, intelligent buildings, energy storage devices, and electro mobility with electric vehicles, along with the associated energy infrastructure such as smart meters, metering management solutions, and automated switches for interruptible load. As the global market leader in power automation, Siemens is involved in a multitude of research and development projects and works with customers to create customized smart grid solutions.

Recently, Siemens and Coulomb Technologies Inc. signed a joint marketing agreement for an integrated electric vehicle (EV) in the fast-moving EV market, including EV charging infrastructure. This agreement will allow Siemens to offer companies—including utilities, electricity retailers, municipalities, and EV suppliers—the ability to monitor, bill, and clear financial transactions for EV infrastructure market participants. In London, Siemens will support the city by becoming a key player in electromobility. The company was nominated as the IT and service partner for the planned installation of 1,300 public charging points.

Siemens will soon turnkey two high-voltage direct current (HVDC) back-to-back links to connect the Georgian power supply network with the grid system in Turkey. As part of the Black Sea Transmission Network Project, one of the most significant infrastructure projects in Georgia, the two HVDC back-to-back links will each be capable of transmitting 350 MW of electric power generated by various hydropower plants in Georgia to Turkey. By using HVDC transmission lines, it is possible to transfer power with losses of no more than 3% per 1,000 km.

Siemens delivered the world’s largest and most powerful 800-kV converter transformer in mid-January 2010. The world-record transformer is destined for the Xiangjiaba-Shanghai link, a HVDC transmission project that spans over 2,000 km with a capacity of 6,400 MW. The HVDC link is currently the longest and most powerful in the world.

Peltier: What are your three key predictions for the power industry in 2011?

Weinhold: The energy system of the future—from power generation to transmission to end user—will be characterized by significantly greater complexity, principally due to the growing demand for electricity and decentralized generation. Only end-to-end intelligence using smart grid technologies will fully enable this integrated energy system and thus our entry into the New Electricity Age. The most important prerequisites are optimized power plants and fleet management that use end-to-end network solutions through integrated communication and new grid intelligence to manage the entire energy network.

A sustainable energy system must include a balance between environmental friendliness, economy, and security of the supply. Many of the technologies for a sustainable energy system already exist—it is just a question of applying them everywhere and worldwide. In order to set up the integrated energy system, three steps have to be completed:

- Optimal selection and allocation of the energy mix.

- Efficiency increase along all steps of the energy conversion chain.

- Holistic optimization across infrastructures and regions using smart grid technologies.

— Dr. Robert Peltier, PE, POWER’s editor-in-chief, conducted and edited this interview.