Monticello Plant Sets Safety Record. Employees at Luminant’s Monticello Steam Electric Station in Titus County, Texas, completed a 16-year safety streak in December 2008, working nine million worker-hours — nearly 6,000 consecutive days — without a single lost-time injury. The achievement is a record for Luminant and its affiliates.

The plant’s safety run began in July 1992. "Since then, Monticello has implemented its Behavioral Base Safety Process as a means to motivate and engage employees in safe operations," Luminant said. "Four times a year, the plant’s behavioral safety team attends workshops designed to enhance safety programs and shares best practices with other industry leaders."

Monticello is an 1,880-MW, three-unit, lignite-fired power plant. Unit 1 began operation in 1974, Unit 2 became operational in 1975, and the last unit, Unit 3, became operational in 1978. Monticello had previously set a national record with three million operational hours without a lost-time accident in 1983. Later that year, the plant also became the first coal generation station to reach four million hours without a lost-time injury.

The National Safety Council, the only known organization to compile national safety records, no longer tracks safe work hours. The last safe work-hour record was logged in 2000, when Carolina Power & Light Co. — now Progress Energy — worked 13,509,233 hours without a lost-time injury.

Monticello’s streak wasn’t the only safe-work industry achievement celebrated last year. In June 2008, workers at Detroit Edison’s 1,100-MW Fermi 2 nuclear power plant in Newport, Mich., completed 10 million hours worked without a lost-time injury. That safe-work period stretched back to June 17, 2002. The 72-month period was the best performance at Fermi 2, surpassing a 52-month stretch of 8.34 million hours from 1992 to 1996.

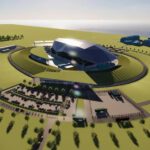

AREVA Submits Eagle Rock COL Application to NRC. AREVA announced in December that its AREVA Enrichment Services subsidiary submitted a license application to the U.S. Nuclear Regulatory Commission (NRC) for authorization to construct and operate its Eagle Rock Enrichment Facility near Idaho Falls, Idaho.

The submission is a major milestone in the development of AREVA’s multi-billion dollar enrichment facility. Eagle Rock will enrich uranium for nuclear power plants using a centrifuge process proven safe and effective over the past three decades. This process also uses a fraction of the energy consumed by older technologies.

The company will continue to complete detailed design work for the Eagle Rock facility and work with the NRC as it reviews the license application. If approved by the authority, construction could begin in 2011 at the Eagle Rock site 18 miles west of Idaho Falls.

TransCanada to Aid Development of Major Canadian CCS plant. TransCanada Pipelines Ltd. has joined power generator TransAlta Corp. in the development of Project Pioneer, Canada’s first fully integrated carbon capture and storage (CCS) plant, the companies announced in December.

When completed, Project Pioneer could be one of the largest CCS facilities in the world, and the first to have an integrated underground storage system. The project will pilot Alstom Canada’s proprietary chilled ammonia process and will be designed to capture 1 megatonne (Mt) of carbon dioxide (CO 2) from an existing TransAlta coal plant in the Wabamun area west of Edmonton, Alberta. The CO 2 will be used for enhanced oil recovery (EOR) and will be injected into a permanent geological storage site.

TransCanada will supply expertise in the design and construction of pipeline infrastructure to Project Pioneer. In addition to TransCanada, TransAlta said it is seeking industry partners from the oil, natural gas, and oil sands sectors who can provide expertise and knowledge across the full spectrum of process plant operations and reservoir knowledge for underground storage and EOR.

TransAlta is submitting detailed funding proposals to both the Alberta government’s CCS initiative and the federal government’s eco-Energy Technology Initiative. It hopes to receive funding commitments during 2009. The company said that if it receives funding from both entities, Project Pioneer will begin in early 2010, with operations commencing in 2012. Preliminary front-end engineering and design work for the project is under way.

"New carbon capture technologies like chilled ammonia show tremendous promise but are not commercially viable at this time. Government and industry partnerships are a critical catalyst required to accelerate their implementation, and provide a sustainable competitive edge for Canada and Canadian companies," said Steve Snyder, TransAlta’s CEO.

Nearly 100 projects worldwide — more than 80 of them in the U.S. — are assessing various aspects of CCS, according to a database compiled by the American Coalition for Clean Coal Electricity (ACCCE). But this figure could be larger: The database (www.americaspower.org/Media/Files/ACCCE-CCS-Database) released last December identifies only projects engaged in government cost-sharing programs; it does not include proprietary projects and technologies that would not otherwise be announced until they are ready for public demonstration. According to ACCCE, some of the projects are actual commercial-scale carbon dioxide storage projects. A few demonstrate commercial use of available carbon capture technologies. The majority represent ongoing research into CCS techniques that are required for broad commercial deployment in conjunctions with coal-based power generation.

Vattenfall Joins the Oxycoal UK Collaboration. Swedish state company Vattenfall announced participation in the Oxycoal UK collaboration, a project to develop a competitive oxyfuel technology for the capture of carbon dioxide that is suitable for full-scale plant application. The project involves burning coal in a mixture of high-purity oxygen and recycled gas to produce a gas rich in carbon dioxide that can be purified and compressed for transportation and storage.

The Oxycoal UK project is lead by technology supplier Doosan Babcock and run by a group of industrial sponsors and university partners. Besides extensive knowledge and experience of CCS-technology, Vattenfall’s contribution to the project will be about £330,000. The project will be running until November 2009, with a possible extension of two years.

In 2008, Vattenfall’s opened its Oxyfuel pilot plant in Schwarze Pumpe and presented plans for new CCS demonstration plants in Denmark and Germany. The company said its primary goal is for CCS technology to be commercially viable in 2020.