Mechanical Dynamics and Analysis (MD&A) was contracted after a forced outage to perform a major overhaul on a cogeneration unit’s MS5001PA gas turbine, and to remove, test and inspect the generator field. Because the unit dispatches as baseload and the turbine is a critical asset, MD&A was asked to complete the repair work as quickly as possible. MD&A met the customer’s expedited schedule, enabling the unit to quickly return to service.

Because the nature of the forced outage was not fully known when the job was awarded, the scope of work initially was incomplete. Despite the uncertainties, MD&A’s experienced technical team quickly evaluated the damage and designed a comprehensive scope of work.

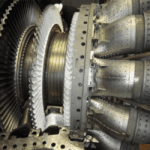

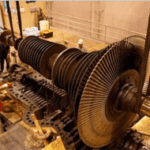

As part of its work, MD&A’s gas turbine maintenance team both opened and closed the gas turbine. In addition, the team removed the original rotor and shipped it off-site for refurbishment and high-speed balance.

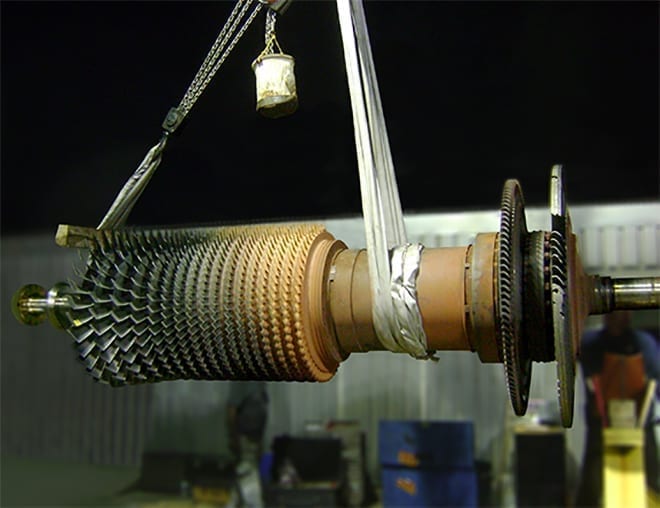

As well, MD&A removed the generator field and sent it to our St. Louis facility for a complete test and inspection, and high-speed balance before being returned to site.

The scope of work included:

Site Work Services

- GT Major Inspection & Rotor Removal

- Generator Major Inspection and test & inspection – the insulation was repaired, flux probes installed and completely re-painted inside

- Stage 9 Stator Hook Fit Mod- removal of Upper & Lower Compressor Casings

- Installed New Electronic Gas Valves – removal of old Hydraulic Gas Valves

- Remove Existing Liquid Fuel System, and associated support systems, such as Atomizing Air and Water Injection – A Controls Software Upgrade to eliminate these control sections

- Accessory and Load Gear Refurbishments

- Exhaust Frame Repairs

Shop Work Repairs

- Gas Turbine Rotor Inspection

- Remove and Inspect 1st stage buckets – Apply coating for excessive rock and repair Aft Angel Wings

- Replace out 2nd stage buckets

- Compressor Blending

- Refurbish HGP Components, Combustion Hardware

- Generator Field Rings Off Inspection, test & inspect, and high-speed balance

- Gas Turbine rotor high-speed balance

New Parts

- 2nd Stage Buckets

- 2nd Stage Shroud Blocks

- Consumables & Hardware

- Auxiliaries

- Exhaust Plenum

MD&A also performed major repairs on the turbines accessory system, such as refurbishment of Accessory & Load Gears, replacement of turbine compartment vent fans, rebuilding of Exhaust Ducting, replacement of Exhaust Expansion Joints, as well as removal of hydraulic overspeed bolt and replacement with redundant electronic overspeed protection.

MD&A’s specialized services range from Combustion, Hot Gas Path and Major Inspections, as well as, Compressor & Turbine Rotor Repairs to Plant Performance Testing and Analysis. We also provide turbine internal alignment to your gas turbine, along with vibration analysis and balance (low-speed & high-speed.)

Call our Gas Turbine Services at (518) 399-3616 or use our Contact form.