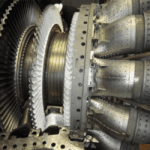

Mechanical Dynamics & Analysis (MD&A) repaired a Frame 5 gas turbine rotor. MD&A replaced 1st and 2nd stage buckets, repaired the seal area on the row 1 turbine wheel, performed compressor blade blending, and machined the thrust collar to accommodate the newer style thrust bearing at the No. 1 bearing.

During their planned major inspection, the utility decided to remove the rotor based on prior recommendations from past borescope findings.

Upon inspection, our gas turbine experts discovered that the Row 1 turbine wheel showed indications of heavy wear caused by rubbing to the rear face of the discourager seal. To repair this, the seal area was prepped and built up using a spray metallizing process.

Once the precise build-up was achieved, the seal area was ground to the correct dimensions and contours. In addition, wear damage to the Row 2 turbine disc sealing area was repaired to achieve an acceptable surface after a fluorescent penetrant inspection was completed.

Experts also performed compressor blade blending from wear damage/FOD to all compressor blade rows. One Row 16 blade was removed and replaced, and non-destructive testing was performed on the repaired rotor.

Progressive balance work was completed on two turbine bucket stages. MD&A experts replaced both stages of buckets.

Our experts also performed the modification to the gas turbine rotor which involved machining the thrust runner face that is located at the No. 1 bearing. This is a common recommendation for the Frame 5 fleet to improve the reliability and operation of the thrust bearing.

Skilled technicians from MD&A’s Bearings, Seals, and Hydraulics Division re-toothed the rotor’s oil deflectors and re-babbitted the bearings.

New replacement buckets were provided by MD&A Parts. The rotor was progressively low speed balanced as the 1st and 2nd stage buckets were installed, technicians secured balance weights and completed the six-point residual unbalance test. The rotor was then packaged & secured on the shipping skid. Finally, MD&A transported the rotor to site and successfully supervised the re-installation.

MD&A’s specialized services range from Combustion, Hot Gas Path, and Major Inspections to Compressor & Turbine Rotor Repairs and End of Life inspections. MD&A offers a complete suite of parts, repairs, and services solutions for the Frame 5 gas turbine fleet.

Call our MD&A Gas Turbine Services today at (518) 399-3616 or use our Contact form