Mechanical Dynamics & Analysis (MD&A) has completed back-to-back major inspections of two 180-MW GE® 7FA.04 gas turbines and 7FH2 generators, returning both to fully dispatchable service on schedule. The complexity of the planning & implementation of these outages for the owner/operator exemplifies the time-proven expertise and capabilities that exists throughout MD&A.

MD&A provided all project management, inspection and analysis, supervision, labor and tooling for the owner’s dual-unit work scope.

During disassembly of the first unit, MD&A Gas Turbine Services personnel first removed roof sections, recorded thrust and lift checks, removed all relevant casings, and labeled/removed relevant piping/hoses. Half shell readings were taken on the turbine and compressor by recording all rotor and stator tip clearances.

The service run 7FA.04 hot gas path components were inspected and analyzed onsite by specialists from MD&A’s San Antonio Service Center to determine the potential for future component repairs. Our team has extensive knowledge on a range of gas turbine component repairs, including weld repair, blending, dimensional restoration, and machining. They can extend the service life of gas turbine components whose OEM service limit has passed or whose configuration is no longer suitable to operate. These experts provided feedback on the component repairability.

For these outages, the turbines’ first, second, and third stage buckets were removed and replaced with Customer provided components.

Additionally, nozzles and shrouds were removed and exchanged. For the compressor, stage 14 through EGV’s stator vanes were removed; new vanes were drilled and pinned upon installation.

MD&A inspected T1 and T2 bearings and determined replacements were required, in addition to new thrust bearings.

All combustion components were removed and inspected. Transition pieces, liners, flow sleeves, outer bellows, inner crossfire tubes and fuel nozzles were exchanged during reassembly.

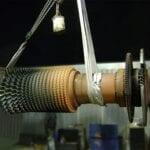

The GE® 7FH2 generator was disassembled, including coolers, oil deflectors, gas shields and bearings. Hydrogen casings and seals were removed and sent to MD&A’s Bearings, Seals and Hydraulics Division in Euclid, Ohio for refurbishment.

The generator field was then removed and transported to our Turbine-Generator Repair Facility in St. Louis, MO for a complete field rewind utilizing the existing copper. The rewind process was expedited to allow for the rewound field to be installed in the sister unit. A spare generator field from the Customer’s inventory was installed on the first unit, to support the expedited outage schedule.

MD&A experts inspected the generator stator and found areas of greasing indicated a loose wedge structure and necessitating a full stator rewedge. Core and bellyband tightening was also required.

Stator electrical testing was completed, and electromagnetic core imperfection detections (ELCID) tests were conducted before and after wedge replacement.

MD&A’s Generator Experts replaced the wedges, then completed bellyband and core tightening. With the stator repairs complete, the generator field from owner/operator’s inventory was able to be installed.

During component reassembly, new hydrogen seals and springs provided by MD&A’s Bearings, Seals and Hydraulics facility were utilized.

Following reassembly of the gas turbines and generators, coupling alignments were performed by MD&A technical experts in full collaboration with the Owner/Operator.

MD&A’s Turbine and Generator Controls Division performed a complete inspection of the exciter and inverter equipment, ensuring no issues on return to service. Startup was completed with no operational concerns and full compliance with emissions standards.

Following execution of the first outage, MD&A personnel shifted focus to the sister unit, to complete a nearly identical work scope.

For this unit, turbine first, second, and third stage buckets were replaced as were nozzles and shrouds.

A spare Customer provided Gas Turbine rotor was installed after conducting green rotor inspections and repairs. At startup the green rotor run-in was completed in compliance with industry standards.

As with other unit, all Technical Information Letters were listed as completed, as were all Extra Work Authorizations.

For this unit, the service run generator field was removed for transport to our Turbine-Generator Repair Facility for a complete field rewind utilizing the existing copper. This field would be rewound and returned to Customer after the outage to be held as inventory.

Conclusion

Throughout these major overhauls on two 7F.04 Gas Turbines and 7FH2 Generators, detailed daily written and visual (photographic) job reports and updates documented all current and planned activities, alerts, needs, schedules, recommendations, and resolutions.

For every repair job, large or small, the speed and effectiveness of our response team is matched only by the depth and breadth of our engineering expertise.

Successful completion of these back-to-back projects clearly exemplifies the multi-divisional breadth, versatility, and corporate commitment of MD&A as a premier non-OEM service provider to the global gas and steam turbine-generator market. Call us at (518) 399-3616 today or use our contact form.