Siemens Energy develops conventional islands for small modular reactors.

When Rolls-Royce SMR began developing its small modular reactor (SMR)—using a unique factory-built approach to proven pressurized water reactor (PWR) nuclear technology—Siemens Energy successfully conducted Rolls-Royce’s partnering assessment process for one of the plant’s most essential components: the steam turbine-generator set. Under an agreement, As a result, Siemens Energy will supply its SST-8000 steam turbine technology, engineered for high efficiency and tailored to the SMR’s modular design. This partnership combines Rolls-Royce SMR’s nuclear reactor technology with Siemens Energy’s conventional island expertise, creating a repeatable, standardized power conversion system ready for global deployment. It’s no surprise.

Nuclear Heritage

For one, there’s the renaissance of nuclear power, along with a focus on SMRs. The latest International Energy Agency (IEA) report on nuclear energy, The Path to a New Era for Nuclear Energy, predicts that under current policy settings, SMR capacity will reach 40 GW by 2050, helping to meet increasing electricity demand and support energy decarbonization. However, if regulations, policies, and industry align, the IEA even considers 120 GW possible, with more than a thousand SMRs in operation.

For another, and in particular, Siemens Energy’s involvement makes perfect sense. With more than 60 years of experience in the nuclear industry, the company stays committed to this sector. Its heritage includes its own Kraftwerk Union (KWU) roots and technological legacies from pioneers like Westinghouse and Parsons.

Powering an Additional 100,000 Homes

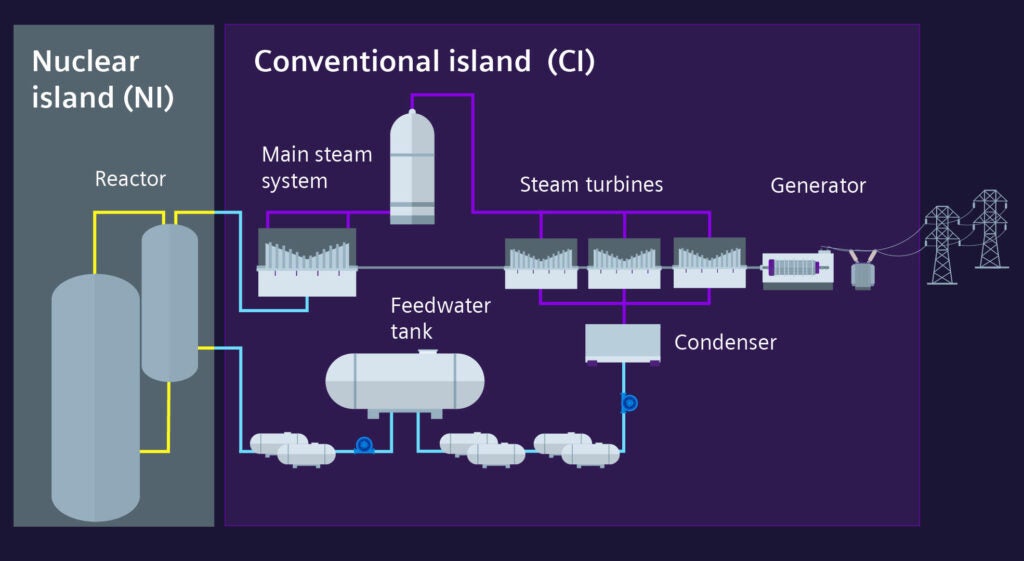

Although Siemens Energy is no longer active on the reactor side, its extensive history shapes its focus on the conventional island in nuclear power plants (NPPs, Figure 1). Even today, about 23% of the world’s nuclear reactors use Siemens Energy’s instrumentation and control (I&C) systems, many of which are combined with the company’s steam turbine-generator sets. And as a long-term service partner in the nuclear industry, Siemens Energy has consistently ensured the safe and reliable operation and, if required, upgrade and modernization of conventional island equipment to accommodate reactor upgrades throughout their lifecycles.

|

|

1. Pressurized water reactor (PWR) nuclear power plant schematic showing the nuclear island (reactor and primary systems) and conventional island (main steam system, steam turbine generator set, condenser, and feedwater tank). Courtesy: Siemens Energy |

For example, Siemens Energy will install 12 low-pressure steam turbines (Figure 2) at the Constellation Braidwood and Byron Clean Energy Centers in Illinois, which will increase output by about 135 MW for the entire power plant—enough to power an additional 100,000 homes. And in Michigan, the company contributes to the historic restart of Holtec’s Palisades Nuclear Plant by inspecting, refurbishing, and upgrading the conventional island. That plant is also planning to host two SMR-300 units in the early 2030s. That shows: Technological development doesn’t stop.

|

|

2. Fully bladed low-pressure (LP) steam turbine rotor in final assembly for a nuclear half-speed modernization application. Damping elements couple the blades to reduce vibration and improve structural integrity of the last blade row. Courtesy: Siemens Energy |

Involved with Multiple SMR Companies

Siemens Energy continues to develop innovative solutions for nuclear power plants. And so, along with nuclear fusion—which Siemens Energy is also investing in—and its continued involvement with large nuclear power plants, it also focuses on the innovation for SMRs.

The partnership with Rolls-Royce SMR is Siemens Energy’s flagship collaboration in the nuclear business, however, the company is still working with other SMR developers to supply product and support to aid their development and deployment. For all these companies, Siemens Energy brings its decades of conventional island expertise to the table, providing turbines, generators, operational I&C systems, and its integration and plant know-how.

Using Far Less Space

But why does so much hope—and promise—ride on SMRs today? SMRs are compact nuclear power plants, often described as “mini-NPPs.” Their modules can be prefabricated in a factory and transported to their final site ready for installation. This modular approach is designed to reduce construction time, cost, and complexity compared to conventional gigawatt-scale nuclear plants.

Unsurprisingly, SMRs may also require far less space, some only about 0.01 square kilometers (km 2), versus 1–2 km 2 for large reactors, and their power output usually have capacities up to 300 MW, with some designs reaching 400–500 MW.

European Units Targeted for the Mid-2030s

The advantages of such a technology are obvious: they offer flexible, demand-based electricity generation with proven nuclear technology safely operating in hundreds of conventional nuclear reactors around the world. The compact, factory-built design also allows them to be deployed in off-grid or remote locations for industrial applications such as powering data centres, hydrogen production, district heating, or industrial heat.

Today, there are operational examples in Russia and China. Additional projects are under construction in countries such as Argentina, and the first commercial-scale European units are targeted for the mid-2030s. So, SMRs are beginning to demonstrate their potential as versatile tools for clean energy supply. These developments not only mark a growing interest in nuclear energy but also face daunting tasks of rising electricity demand and decarbonization goals. They are also based on continued innovation of nuclear technology, which makes SMRs appear feasible today.

Muscle and Brain for SMRs

On the SMR’s reactor side, technologies being developed range from scaled-down light-water reactors to innovative designs like high-temperature gas-cooled reactors, sodium/lead fast reactors, and molten salt reactors, each targeting different applications and fuel strategies. On the conventional island’s side, the push for modularization also drives innovation. It’s an approach Siemens Energy already applies successfully in combined cycle power plants through standardized, pre-assembled skids and plug-and-play auxiliaries (such as lubrication, sealing, cooling, and control) that shorten installation and commissioning.

This building-block philosophy benefits SMRs, since they also need factory-built, transportable components. Steam turbine and generator designs (Figure 3) for these units are compact and customized for SMR output ranges, while ensuring nuclear-grade reliability. Siemens Energy can develop single-lift concepts as needed—for example, the company recently executed a 120-MW “single lift turboset.”

|

|

3. Blades being inserted on an LP steam turbine rotor. Three-dimensional blading improves efficiency by up to 2% over conventional designs, while 3DV technology (three-dimensional blading with variable degrees of reaction) adds another 1% through automated computational optimization. Courtesy: Siemens Energy |

Finally, drawing on Siemens Energy’s extensive nuclear expertise, they include I&C applications that are easily adapted for SMRs. Specifically, the Omnivise digital ecosystem by Siemens Energy integrates plant monitoring, diagnostics, and performance optimization. It’s the “brain” of the power plant, while the turboset provides the “muscle.”

The Challenges Ahead

Yet, as promising as these developments are, it’s clear that SMRs still encounter familiar challenges faced by large nuclear plants: navigating complex regulations, controlling costs, and managing spent fuel. For the latter, part of the answer may be that SMRs generate less nuclear waste—and some of the latest reactor designs, often called advanced modular reactors (AMRs), aim to close the fuel cycle by using nuclear waste as fuel. But beyond these technical issues, the fundamental challenges remain: rising energy demands, the need to decarbonize, while at the same time ensuring energy security.

—Dagmar Thien is manager of conventional island nuclear power plant equipment with Siemens Energy.