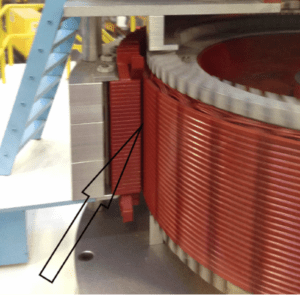

An air gap is the distance between the rotor and stator of a large-scale hydroelectric generator. This gap is a very small distance in relation to the size of the rotor. Its measurement to tight tolerances is critical to prevent damage to and maintain efficiency of the generator. Static measurement of the air gap (Figure 1) is required during initial installation, periodic maintenance checks, and again at reassembly of the generator following major maintenance operations.

There are many sensors available for dynamic monitoring of the air gap when the generator is rotating. However, typical tools for static measurement of the air gap prior to generator rotation called “parallels” take the measurement mechanically, which is a time-consuming process.

Kaman has developed a portable measurement device that helps reduce downtime by providing a fast, repeatable, and reliable means of measuring the static air gap in hydrogenerators. Kaman’s new static air gap tool (AGT) takes this static measurement electronically simply by sliding the spring end of the robust measurement paddle into the gap between the rotor and stator (Figure 2). Compression of the springs to match the gap is measured in real time by an eddy current sensor coil located between the springs. The compression springs are wide enough to account for variability in different rotor and stator windings. This permits the tool to be used with different winding sizes and patterns without adjustment.

Signal conditioning electronics at the handle end of the paddle accurately translate the inductance change in the sensor coil to distance —available in imperial or metric units—and wirelessly transmit to the operator’s handheld device. The AGT (Figure 3) is user-friendly and accurate. Like the parallels, the AGT can be used in any orientation, horizontally or vertically, depending on the design of the generator. The AGT is powered by a long-life rechargeable battery permitting up to eight hours of operation between charges.

A Complete, Connected Solution

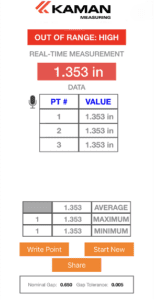

Measured distances are displayed and stored in a user-friendly app available for both iOS and Android devices. Instructions for download are included with purchase of the tool (mobile device not included).

During typical use, operator A positions the tool between the rotor and stator poles. Operator B then records data via the mobile app. This can be done either by voice command or touching the “Write Point” button on the mobile device display (Figure 4). The app then sequentially numbers the data points and stores them, leaving no need for an operator to record manually. Data can be viewed in the app and downloaded to a personal computer for storage and analysis. This download feature is a major time saver for operators and eliminates possible manual data entry errors.

When the mobile app is launched, it will automatically search for an AGT within Bluetooth range, which is typically 10 ft. to 15 ft. An AGT within range will display on the screen and connect upon operator command. The intuitive user interface is easily set up prior to taking measurements. Main features include:

- Entry of the installation or generator number.

- Entry of high and low display limits of acceptable gap measurements.

While the AGT is designed to wirelessly communicate with the app on the mobile device, some environments may have too much background interference for reliable communications. If a communication interruption occurs, recording of measurements resumes from the last data point when communication is restored.

For environments with higher interference or installations where wireless is not desired or permitted, the AGT and handheld device can be connected via a USB cable. In acoustically noisy environments, a headset connected to the handheld device is recommended when using voice commands. The handheld device should be maintained within six feet of the AGT for the most reliable operation.

The AGT is supplied with factory calibration to NIST traceable standards for measurement ranges from 0.4 inch to 1.3 inches. With factory calibration, measurement accuracy is 0.001 inch over the entire measurement range. If an operator has a calibration lab to set the compression springs to specific distances, then a calibration check or recalibration can be done within the app.

Simplifying Real-World Complexities

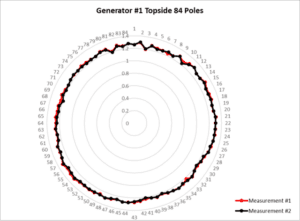

Recent testing at a large-scale U.S. hydroelectric generating facility reported reduced measurement time over previously used parallels. Measurements with the parallels required two hours to check every third pole, whereas measurements with the AGT required only 30 minutes to take measurements of every pole. Since data was required for both above and below the rotor, the AGT was able to realize a time savings of three hours.

At this same facility, the operator quickly downloaded data from the app into an Excel spreadsheet and generated a radar plot (Figure 5). The data is displayed with the actual pole number. Two sets of data were taken by two different operators to verify repeatability of the measurements. As can be readily seen, results are consistent. A quick review of the data can reveal inconsistencies or potential problem locations that should be verified.

While other tools can measure hydroelectric rotor and stator alignment to an acceptable level, none can compete with the speed and precision of the Kaman static AGT.

—POWER edited this content, which was contributed by Kaman Measuring.