Long Ridge Energy Terminal will transition a 485-MW combined cycle power plant that is under construction within its sprawling multimodal facility on the Ohio and West Virginia border with the capacity to run on a hydrogen blend when it begins operation in 2021, and eventually transition to 100% green hydrogen within a decade.

Long Ridge, which is developing the 1,660-acre facility in the heart of the Marcellus and Utica shale formations, is collaborating with global energy infrastructure firm New Fortress Energy and GE Power to put the Long Ridge Energy Generation plant online by November 2021, alongside other natural gas infrastructure, including two storage tanks and four gas pipelines.

The power plant will deploy a GE 7HA.02 combustion turbine, which, as GE Power noted, “can burn between 15% to 20% hydrogen by volume in the gas stream initially, with the capability to transition to 100% hydrogen over time.”

Because it has access to industrial byproduct hydrogen nearby, the power plant could begin burning a blend of hydrogen in a gas stream “as early as next year,” Long Ridge said. “For the production of green hydrogen with electrolysis, Long Ridge has access to water from the Ohio River. Over time, below ground salt formations can be used for large-scale hydrogen storage,” it said.

Along with Long Ridge’s proximity to large-scale storage, “the plant will be capable of supporting a balanced and diverse power generation portfolio in the future; from energy storage capable of accommodating seasonal fluctuations from renewable energy, to cost effective, dispatchable intermediate and baseload power,” the companies said in a joint statement.

A Big Hydrogen Deal for GE

The development is another definitive milestone for GE, which has marked a stream of notable steps to exploit the lucrative hydrogen power niche in an ever-more-competitive global gas turbine market. When online, Long Ridge will become “the first purpose-built hydrogen-burning power plant in the United States and the first worldwide to blend hydrogen in a GE H-class gas turbine,” GE said on Tuesday.

The Long Ridge project comes just months after GE Gas Power agreed to form a joint working group to explore, assess, and develop technology and service options for decarbonization of German generation giant Uniper’s 4-GW GE gas turbine fleet. Under that agreement, the two companies expect to work out a detailed roadmap that may entail hydrogen-friendly upgrades to all GE gas turbines and compressors at the German generation giant’s gas power plants and gas storage facilities across Europe.

Still, GE faces stiff competition from other gas turbine market contenders, including Siemens Energy, which is spearheading a four-year power-to-hydrogen-to-power project in France, and Mitsubishi Power, which this September rolled out standardized hydrogen storage and site integration packages.

But according to Scott Strazik, CEO of GE Gas Power, GE is already “one of the leaders in decarbonization in the gas turbine industry,” mainly because it is an original equipment manufacturer “with the most fleet experience in using alternative low heating value fuels,” including hydrogen. Strazik said on Tuesday that GE looks forward “to applying more than 80 years of experience to help Long Ridge achieve its goal of providing reliable, affordable, and lower-carbon power to its customers.”

What a Hydrogen Conversion May Entail

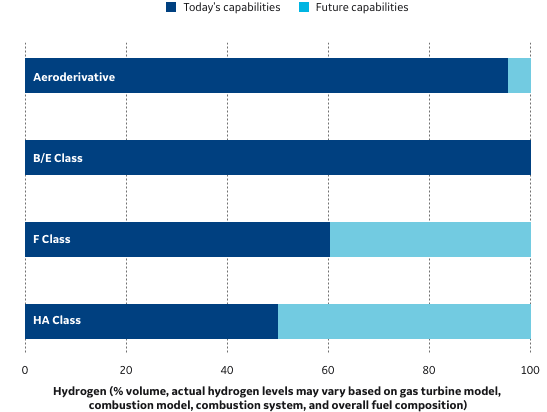

A GE spokesperson on Tuesday meanwhile pointed out that GE Power has already deployed a broad range of combustion technologies across its gas turbine portfolio that “enable a wide range of hydrogen concentrations—up to 100% (by volume)—on its aeroderivative and B/E class fleet.” To date, “Our advanced-class fleets (F, H-class) have configurations that allow operation on fuels up to 50%–60% (by volume) hydrogen concentration (depending on the specific gas turbine)—with technology paths to higher concentrations depending on customer needs,” the spokesperson said.

The HA gas turbine is capable of 50% hydrogen by volume “for units with the DLN 2.6e combustion system, which is found on the 7HA.03 (60Hz) and the 9HA.01 and 9HA.02 (50Hz),” the spokesperson explained. However, “the combustion system on the 7HA.02 [the model to be used at Long Ridge] is a DLN 2.6+, which will allow them to start out with up to 15-20% hydrogen by volume right away with an upgrade path to greater percentages of hydrogen over time,” he said.

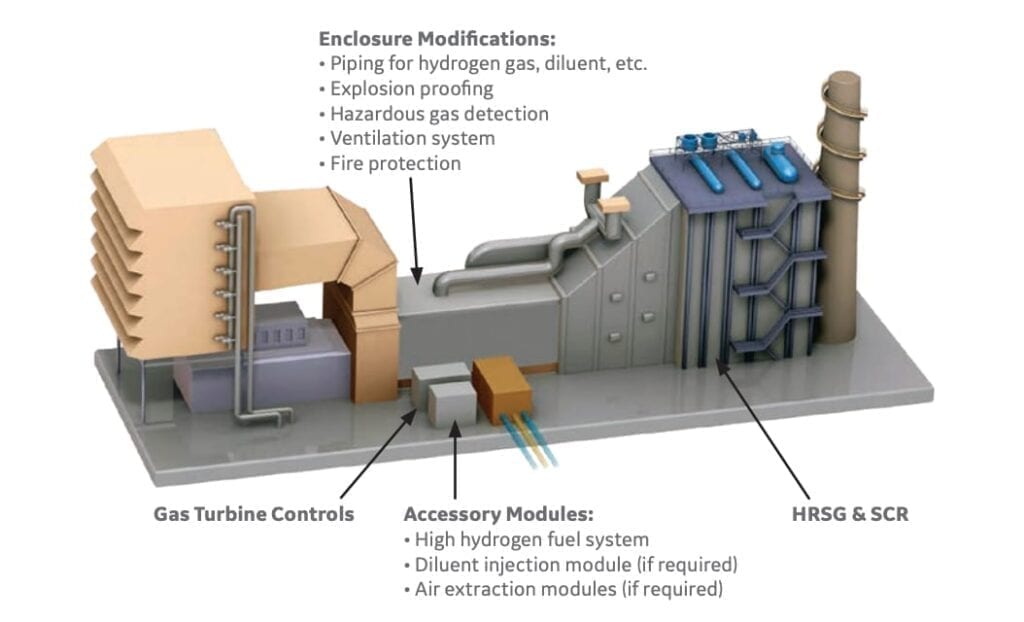

Asked what modifications and upgrades the 7HA.02 could require to reach a 100% capability, the spokesperson said “there are number of things we will want to work on with any customer utilizing hydrogen to ensure plant reliability and safety.” As described in a recent white paper authored by Dr. Jefferey Goldmeer, GE Gas Power’s Emergent Technologies director for Decarbonization, the scope of work also varies depending on the amount of hydrogen in the fuel.

“If the new fuel will be a blend of hydrogen in natural gas, the required changes might be limited controls updates along with new combustor fuel nozzles,” Goldmeer writes. But if the conversion is to a high-hydrogen fuel, a fuel conversion “may require switching to a new combustion system, which would require new fuel accessory piping and valves. It may also require new fuel skids, as well as enclosure and ventilation system modifications,” he said.

“Other changes necessitated by the safety concerns … include upgrading to flame detectors capable of detecting [hydrogen] flames and upgrading gas sensors to models configured to detect gases with reduced levels of hydrocarbons.” Beyond physical changes, switching to a high hydrogen fuel may require changes “to the gas turbine controls, which might impact gas turbine performance, both output and heat rate,” as well as the larger balance of plant scope, he said.

Power to Gas: Hydrogen for Power Generation (GE, 2019)

A New Frontier for NFE

The Long Ridge prooject, however, is also a major development for NFE, which recently launched a new division, “Zero,” to deploy emerging hydrogen production technologies. NFE’s website says the division could transform the company “into one of the world’s leading zero-carbon power providers.”

Wes Edens, NFE CEO and chairman, said on Tuesday, “Long Ridge has many advantages in the pursuit of green hydrogen and zero-carbon power and this partnership allows us to get firsthand knowledge and experience blending hydrogen and natural gas in GE turbines.” Edens also noted that NFE’s focus has been to “identify and support clean technologies that can eventually produce hydrogen at commercially attractive prices.” Progress at Long Ridge, which Edens described as an “advance proof of concept” project, will “bring tremendous value,” he said.

Long Ridge said it has also engaged Black & Veatch to help develop plans for the plant’s integration of hydrogen blending and “to ensure safe and reliable industrial practices.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Updated (Oct. 13): Adds details about GE’s gas turbine fleet’s hydrogen capabilities, and what a hydrogen conversion could entail.