Upcoming revisions to U.S. federal effluent guidelines are anticipated to include new discharge limits for mercury and selenium in flue gas desulfurization wastewater, in addition to other potential revisions. Collaborative R&D is helping inform the rulemaking and is evaluating the cost and performance of technology options that might be used to meet the new targets.

The U.S. Environmental Protection Agency (EPA) is revising effluent guidelines for the steam electric power industry that could change how many power plants manage and treat wastewater. The proposed EPA rule is scheduled for release for comment in November 2012; final rule approval is expected by April 2014. Once finalized, the EPA’s guidelines may impose new limits on wastewater discharges at power plants that would be incorporated into the plant permitting process. The specific details of the guidelines remain unknown at present, but they may include the first-ever nationwide limits on mercury and selenium discharges from flue gas desulfurization (FGD) systems and may also include new limits on fly and bottom ash transport water, landfill leachate, and metal cleaning wastes.

|

| 1. Selenium experiments. Selenium chemistry in wet FGD systems is highly complex and not completely understood. EPRI pilot-scale simulation tests are improving our understanding of the factors that affect selenium speciation and phase partitioning in wet FGD systems. Courtesy: EPRI |

Selenium experiments. Selenium chemistry in wet FGD systems is highly complex and not completely understood. EPRI pilot-scale simulation tests are improving our understanding of the factors that affect selenium speciation and phase partitioning in wet FGD systems. Courtesy: EPRIAmong the potential range of outcomes, new limits on mercury and selenium in FGD wastewater discharges could represent the most significant consequences for the power generation industry—for coal plants in particular.

To support its rulemaking, the EPA issued an Information Collection Request (ICR) in June 2010—an extensive industry questionnaire to obtain data on water management practices at power plants. The agency also conducted sampling and analytical studies at eight power plant FGD wastewater treatment systems. The EPA has been using the data to gauge the applicability and overall performance and costs of wastewater treatment options. Ultimately, the agency will identify the “best available technology” (BAT) and propose new standards based on this technology’s expected performance.

100112_Wtr%26Pwr_Fig_2.jpeg2. Trace metal removal tests. A pilot scale iron-based treatment technology is being used by EPRI to test methods of trace metal removal from FGD wastewater.

Courtesy: EPRIFor power plants, the costs to comply with potential new limits on mercury and selenium discharge could be significant and will depend upon the treatment approach as well as which pollutants are regulated and at what level. The Electric Power Research Institute (EPRI) estimated that capital costs could range from $25 million to $50 million for a physical/chemical FGD wastewater treatment system to more than $100 million for a thermal zero liquid discharge (ZLD) wastewater treatment system. Multiplying those costs by the number of potentially affected power plants pushes the potential price tag for this regulation well into the billions of dollars. In addition to the costs for removing mercury and selenium from FGD wastewater, there are numerous technical challenges. As a result, FGD wastewater treatment has been a high priority for research and development (R&D).

R&D for Informed Decisions

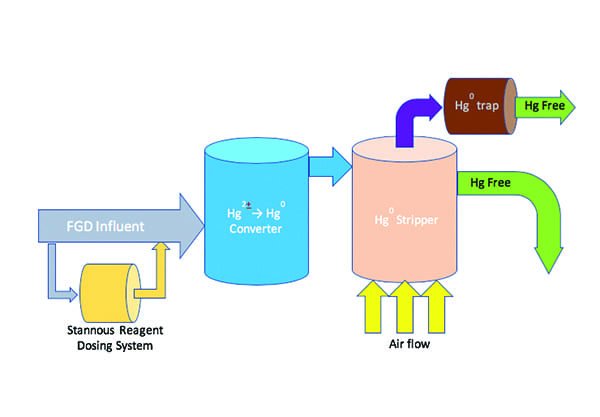

To inform the rulemaking process and support scientifically based decision-making, EPRI is conducting a parallel evaluation of the EPA’s ICR data. The evaluation is part of EPRI’s multiyear collaborative R&D program that also includes characterization of FGD wastewaters, evaluation of mercury and selenium chemistry in FGD wastewaters, and evaluation of an array of wastewater treatment technologies. EPRI’s technical analyses inform all stakeholders, including the EPA, industry, and the public, so regulatory decisions can draw upon a foundation of independent information.

Focus on FGD, Mercury, and Selenium

Many FGD systems have been or will be installed to reduce air emissions of sulfur dioxide, as well as mercury and selenium from coal-fired power plant stack gases; however, these systems may create new waste management challenges.

Constructed wetland. This pilot vertical flow wetland treatment system for selenium and mercury showed promising results. Courtesy: EPRI Also known as wet scrubbers, FGD systems use a slurry of water and limestone or other alkaline material to remove sulfur dioxide from power plant exhaust gases. Sulfur, mercury, and selenium occur naturally in coal and are released during combustion. Mercury and selenium exist primarily in vapor phase in flue gas. They may pass through the power plant’s particulate control device, such as the electrostatic precipitator (ESP), and thus are captured in the wet FGD system. The majority of the mercury and selenium becomes sequestered in the FGD solids. Small amounts, often in the parts per billion (ppb) range, end up in the FGD wastewater. The revised effluent guidelines will likely affect the way FGD wastewater (and other wastewater) is managed before it can be discharged.

Although the proposed federal effluent guidelines have yet to be released, many states already regulate mercury and selenium in FGD wastewater. Some northern Midwestern states, for example, have established mercury discharge limits at 1.3 to 12 parts per trillion (ppt) and selenium limits at 10 to 100 ppb. It is unclear whether existing treatment technology can consistently and reliably reduce concentrations to these levels for all FGD wastewaters on a continuous basis. The limited data available demonstrate significant variability in trace element removal (especially for mercury) among different power plants and FGD systems, as well as within operational parameters of a single FGD system. A number of factors may affect treatment performance, such as the coal properties, FGD design and operations, chemical additives, makeup water quality, and limestone properties.

Removing mercury and selenium from FGD wastewater is difficult for several reasons. First, these trace metals are present in very low concentrations in FGD wastewater—mercury in concentrations of about 1 ppb. To appreciate the challenge of treating wastewater trace metals at the part per trillion level, consider that the Louisiana Superdome could hold about one trillion ping-pong balls. If one thousand of these trillion ping-pong balls represent “mercury balls,” you would have a concentration of one part per billion. To reduce the concentration to one part per trillion, one would have to find and remove 999 out of 1,000 mercury balls from the trillion other ping-pong balls. And this must be accomplished continuously, every day, under all operating conditions to meet typical permit requirements.

|

| 3. Constructed wetland. This pilot vertical flow wetland treatment system for selenium and mercury showed promising results. Courtesy: EPRI |

To compound the challenge, scientific understanding of the chemical behavior of mercury and selenium in FGD wastewater is incomplete. In particular, current knowledge of mercury’s behavior is anecdotal and vague, and it cannot satisfactorily explain why mercury is so difficult to remove or why the effectiveness of mercury capture varies from plant to plant.

One possible explanation for the difficulty of mercury removal is that, upon entering FGD wastewater, mercury generally will react and bind with almost anything. These reactants may include chloride, bromide, and sulfur, as well as organic material. In some cases, it appears that mercury may form submicron-sized compounds that are too small to be filtered out of the wastewater and too tightly bound to further react with wastewater treatment compounds. Another potential source of variability is the limestone reagent, which contains small percentages of various other compounds (known as inerts) that may affect mercury (and selenium) chemistry and thus treatability.

Selenium presents complications of its own. Selenium in FGD wastewater is present in two primary forms, or valence states: selenite and selenate. Selenite is relatively easy to remove with traditional iron-based water treatment products, but selenate is far more difficult to remove. Selenium also exists in other forms, and each form may have its own treatment challenges.

EPRI is working to identify which species of selenium and other metals are present in FGD wastewater and how this speciation affects the removal rates and costs/benefits for each treatment technology (Figure 1).

Further adding to the complexity of treating FGD wastewater, more FGD systems are being installed as sulfur regulations are tightened further. Different FGD designs, variations in limestone composition, different types of coal, coal blending and switching, and variations in water composition at different power plants all interact to influence mercury and selenium chemistry and affect the success of treatment. This complexity raises concern that some power plants may be unable to treat and discharge FGD wastewater to meet new limits on mercury and selenium, especially on a continuous basis and for all foreseeable operating conditions and coals.

EPRI has also seen data excursions (that is, wide swings of removal rates) on existing water treatment systems. Analyses of the operational parameters and chemical properties involved have not been able to explain the excursions to date. It will be important to quantify what conditions can lead to such excursions so that they can be avoided or mitigated, or so that data can provide the basis for a permit variance process to address the excursions.

Treatment Technologies and Discharge Limits

There are several FGD wastewater treatment technologies. Each type has its advantages, costs, and performance limitations in terms of consistently and reliably removing mercury and selenium to extremely low concentrations. EPRI research will help facilitate developing as many solutions as possible and will evaluate treatment options and costs to help power plant operators make informed decisions.

Physical/Chemical Technologies. Physical/chemical technologies remove trace metals through adsorption or precipitation. A typical approach involves adding sulfides that react with mercury to form insoluble cinnabar.

A problem with this method is mercury’s high reactivity: The cinnabar particles form almost instantly and are so tiny they are difficult to remove with filtration. Thus, the current practice is to use larger organosulfide compounds to promote the formation of larger particles that are easier to collect. Iron coprecipitation is the most common technology currently used to treat selenium and other metals. Iron coprecipitation is effective in reacting with selenite, but selenate remains in solution. EPRI is evaluating a more advanced zero valent iron technology that may be effective in removing selenate and selenite, as well as mercury (Figure 2).

Biological Treatment. Biological treatment systems employ anaerobic bacteria to reduce selenium, and they also change mercury to its elemental forms or to precipitates that fall out of solution.

One option for biological treatment is the bioreactor, which uses specially selected strains of bacteria, pumps, tanks, piping, and process control to optimize selenium and mercury removal. Commercial bioreactor treatment systems are available, and five are now in operation on FGD wastewater. In general, selenium removal is very good, usually to levels less than 10 ppb; however, mercury removal is more variable and more uncertain.

Another potential option for biological treatment is a constructed wetland. EPRI has collaborated with utilities to demonstrate constructed wetlands for wastewater treatment systems, including traditional wetlands, and is now studying a more novel vertical flow design (for anaerobic treatment of selenium). In the vertical flow wetland, wastewater flows down through a thick layer of bacteria-rich material, typically compost. Only one such application is currently in operation (Figure 3).

The underlying selenium chemistry of these biological treatments is similar, but it is important to note that the mercury chemistry is not well understood. EPRI is currently conducting laboratory studies to evaluate the mercury chemistry, and the limited data suggest that the mercury reactions are different from the selenium reactions. Mercury chemistry appears to be sensitive to variations in FGD wastewater composition. For example, when a power plant recently temporarily switched to a different type of coal, the performance of the biological treatment system declined significantly, for reasons that are still unclear.

Zero Liquid Discharge. Another type of treatment is thermal zero liquid discharge. This technology uses thermal energy to evaporate the wastewater and then recovers the water for reuse.

Thermal ZLD may be an option in cases where the discharge limits cannot be achieved by existing physical/chemical and biological treatment approaches, where water conservation is a high priority, and for future new plants that have stringent discharge requirements. There are only a handful of ZLD systems operating on wet FGD wastewater (primarily in Italy).

ZLD is a capital- and energy-intensive approach. In addition, ZLD systems have experienced issues with corrosion and scaling when operating on FGD wastewater.

Merrimack: A Preview?

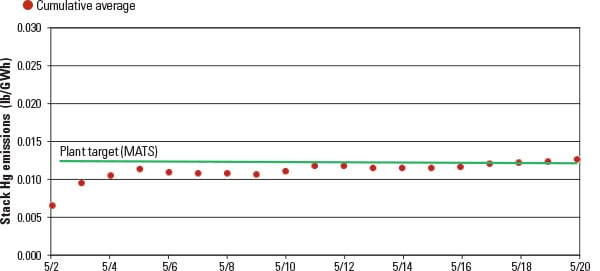

The level of treatment performance that will be required under the new effluent guidelines will not be known until the EPA issues its proposed rules. However, the EPA’s draft permit for wastewater discharge at Public Service of New Hampshire’s Merrimack Station (see p. 34) may provide insight into the direction of the national regulations.

In the draft permit, the EPA identified physical/chemical plus biological treatment as BAT for selenium, and physical/chemical treatment as BAT for mercury. Based on this determination, the agency proposed a daily maximum mercury limit of 14 ppt. The proposed selenium limits are a daily maximum of 19 ppb and a monthly average of 10 ppb. In determining BAT, the EPA also provided a summary of its cost/benefit assessment of the treatment systems selected.

EPRI reviewed the draft Merrimack permit and a number of the supporting documents. The analysis found that the EPA’s estimated capital and operating costs for the physical/chemical and biological FGD wastewater treatment were low compared to EPRI’s estimates. The EPA did not provide detailed itemization of its cost estimates, so EPRI was not able to identify where the estimates differed. One possible explanation is that the EPA’s estimates incorporate primarily the direct equipment and installation costs but may not incorporate all the indirect costs, including engineering, construction, contingency, startup and commissioning costs, which are significant and can represent approximately twoâ€thirds of the total capital costs in such projects.

In addition, the EPA’s estimated benefits (removal calculations) for biological treatment were high relative to EPRI’s estimates. EPRI estimated benefits using the dataset from the EPA’s sampling and analytical studies at two power plants employing physical/chemical plus biological treatment systems. EPRI’s benefit estimates were consistently two orders of magnitude less than the EPA’s estimates for the efficacy of biological treatment. As with the cost estimates, there was not enough breakdown in the EPA’s benefits estimates to understand the differences with EPRI’s estimates.

Closing Knowledge and Technology Gaps

The differences in the cost and performance estimates for FGD wastewater treatment at Merrimack underscore the need to better understand the available data and the limitations in extrapolating from that data to the broader industry in order to determine limits on mercury and selenium that can be achieved in a consistent and cost-effective manner.

Ongoing collaborative R&D efforts aim to improve knowledge about the many variables affecting the cost and performance of FGD wastewater treatment technologies. These include the type of FGD system, type of coal and limestone used, wastewater composition, type of treatment technology, mercury and selenium chemistry, microbiological removal chemistry, and the impact of multiple environmental regulations on power plant operations and economics. Better knowledge informs the rulemaking and supports informed decision-making as well as performance improvements and cost reductions in treatment technologies.

In addition, more accurate treatment costs and performance information is essential for power plants to evaluate compliance options. As the Merrimack estimates show, it is important that technology cost/benefit assessments consider all costs, including indirect costs that may be considerable. EPRI has developed and is applying advanced models to estimate treatment costs more accurately and to understand the factors that influence costs.

An ongoing physical/chemical water treatment optimization study aims to identify improvements that can be made to existing FGD wastewater physical/chemical treatment systems and to characterize the levels of contaminants that these improvements can achieve for a range of trace metals.

EPRI and utilities also continue to evaluate promising advanced treatment technologies. These include vertical flow wetlands and bioreactors in pilot and full-scale installations as well as physical systems such as zero valent iron, novel adsorbent materials, and ZLD systems.

As rulemaking on steam electric effluent guidelines proceeds, the results of collaborative R&D will continue to support the stakeholder community with the best information available on the cost, performance, and reliability of technologies that may be called upon to meet future limits.

—Paul Chu (pchu@epri.com) is senior project manager, Water and Ecosystems for the Electric Power Research Institute.