The VVER (water-water energetic reactor) technology was born during the time of the Soviet Union. In its main features (light water under pressure as coolant, low-enriched uranium fuel, two-circuit design), it coincided with the Western PWR) pressurized water reactor) technology, but it was not an exact copy. At best, VVER and PWR can be called cousins.

COMMENTARY

VVER reactors endured tough competition with other reactor technologies developed in the former USSR and Russia, and ultimately secured their niche as thermal neutron reactors in Russian state-owned nuclear group Rosatom’s strategy of developing a two-component nuclear power industry with both thermal and fast reactors and a closed nuclear fuel cycle.

VVER-1000: From Novovoronezh to China and India

The first member of the family of high-capacity VVER reactor units, providing 1000 MWe per unit, was the V-187 design, developed by OKB Gidropress designers in the 1970s.

Since then, this once small design bureau in Podolsk near Moscow has transformed into a world-famous design and production organization within Rosatom’s Mechanical Engineering Division. Today, OKB Gidropress develops all new VVER projects.

The V-187 design was implemented at Unit 5 of the Novovoronezh NPP (commissioned in 1980). The project proved successful—all design goals were achieved, and the unit continues to operate today.

Comparison of the key parameters and technical solutions of the V-187 showed that the Soviet newcomer was not inferior to advanced Western PWR designs, and even surpassed them in some respects. For example, the adopted hexagonal fuel assembly shape allowed better use of core space and reduced vessel diameter, while the thinner fuel rods (9.1 mm diameter with 12.75 mm pitch) ensured higher heat transfer surface and greater power density (up to 110 kW/l).

The V-187 lagged behind Western competitors in unit power, as Western designs considered 1300 MWe. However, Gidropress’ detailed analysis showed no fundamental obstacles to increasing VVER power above 1000 MWe. The only limitation was reactor vessel transportability by rail, restricting maximum vessel diameter to about 4.5 meters.

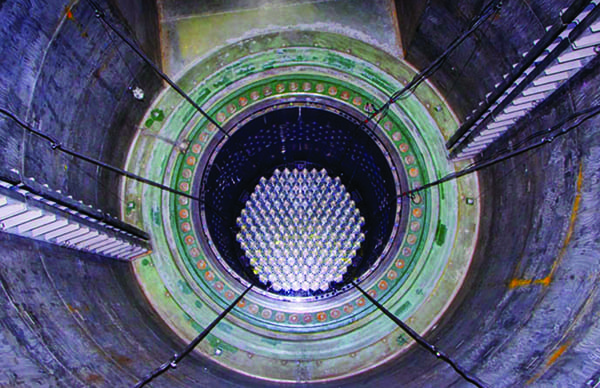

VVER reactors were brought to series production in the V-320 design, which significantly differed from the V-187 one with optimized layout (e.g., removal of main gate valves DN 850 in the primary circuit loop) and reactor design changes—vessel, upper block, and internal structures. Fuel design also changed, with the transition to canless fuel assemblies enabling a three-year lifetime. Measures were taken to improve operational reliability and safety. Units with V-320 design were built in Russia, Ukraine, and exported to Bulgaria and Czechoslovakia. In post-Soviet Russia, V-320 design was implemented at the four-unit Rostov NPP and several units of Kalinin (Figure 1) and Balakovo NPPs.

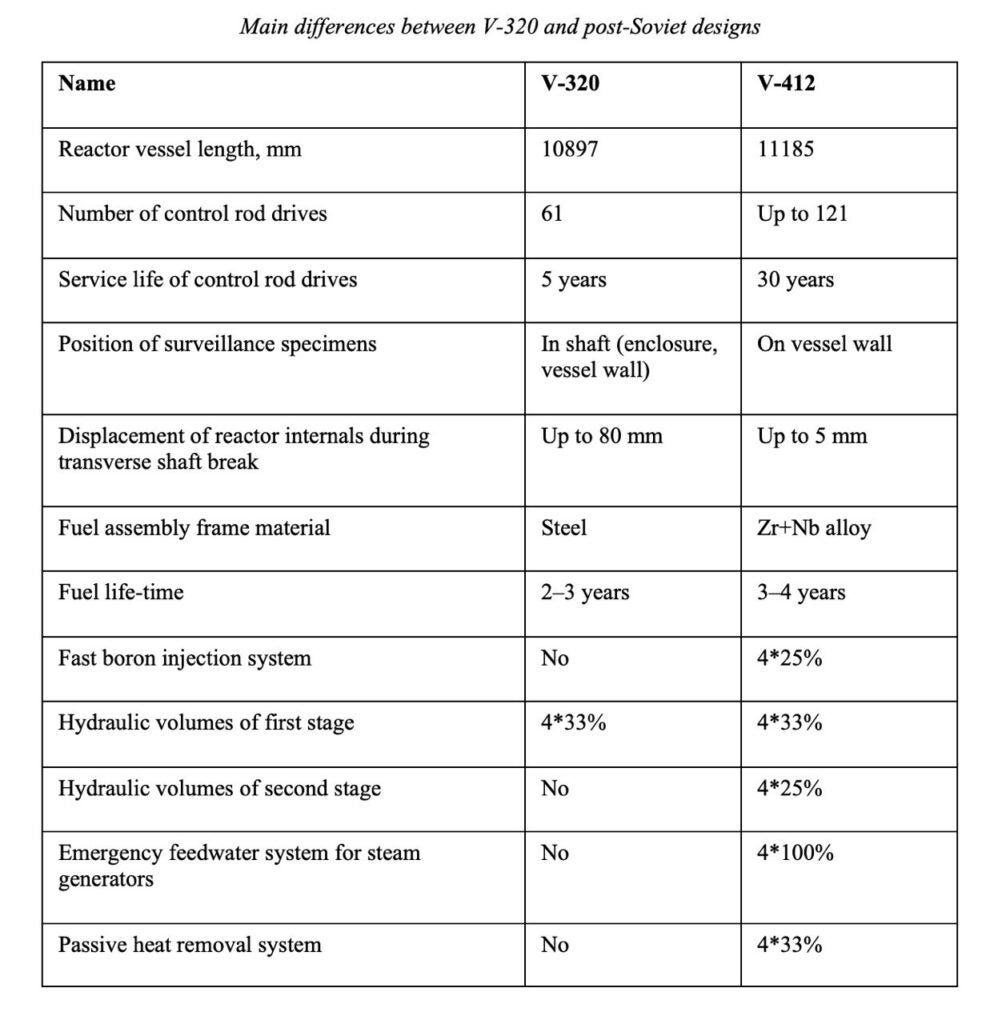

Further development of VVER-1000 technology followed two close directions: the V-428 design for Tianwan NPP in China, and the V-412 design for Kudankulam NPP in India. The Chinese V-428 preserved most V-320 solutions, but incorporated operational experience and International Atomic Energy Agency (IAEA) recommendations: a four-channel safety system, double containment, extended spent fuel pool storage (10 years), improved seismic resistance, and design life increased up to 60 years.

The Indian V-412 was similar but emphasized expansion of design and beyond-design-basis accidents covered by passive safety systems, and specific seismic requirements for Kudankulam.

New High-Capacity VVER Units

Consolidation of Russia’s nuclear industry under the Rosatom umbrella, the development of technological capabilities at machine-building plants, and the easing of logistical constraints enabled Russian nuclear engineers to tackle a problem that their Soviet predecessors, for objective reasons, were unable to solve—namely, increasing the power output of the VVER-1000 reactor.

As a result, the AES-2006 Generation III+ project with the VVER-1200 reactor unit was created. It was designated as the new serial design for construction both in Russia and abroad.

It is important to note that the emergence of the VVER-1200 did not retire the VVER-1000. The China V-428 and India V-412 projects successfully demonstrated their technical and economic viability under market economy conditions, which is why the Indian project continues to be implemented at Kudankulam NPP. In one form or another, the VVER-1000 will remain in demand in the coming years in Russia’s Far East, and possibly in Uzbekistan.

As for the VVER-1200, four units are already in operation in Russia and two in Belarus (Figure 2), with the first being Unit 6 of the Novovoronezh NPP in central Russia, commissioned in 2016 with a reactor built to the V-392M design. Symbolically, it was constructed next to a unit of the V-187 design, which marked the beginning of the history of high-capacity VVER reactors.

In addition, VVER-1200 reactors will operate at nuclear power plants currently under construction in China, Turkey (Figure 3), Bangladesh, Egypt, Hungary, and Kazakhstan. It is worth remembering that engineering innovation never stops: today Rosatom engineers are actively working on a unified standardized design intended to incorporate the best elements of Russia’s high-capacity NPP designs.

The goals of the AES-2006 design included enhancing safety, optimizing project timelines and costs, improving the competitiveness of NPP units, and increasing maneuverability and maintainability.

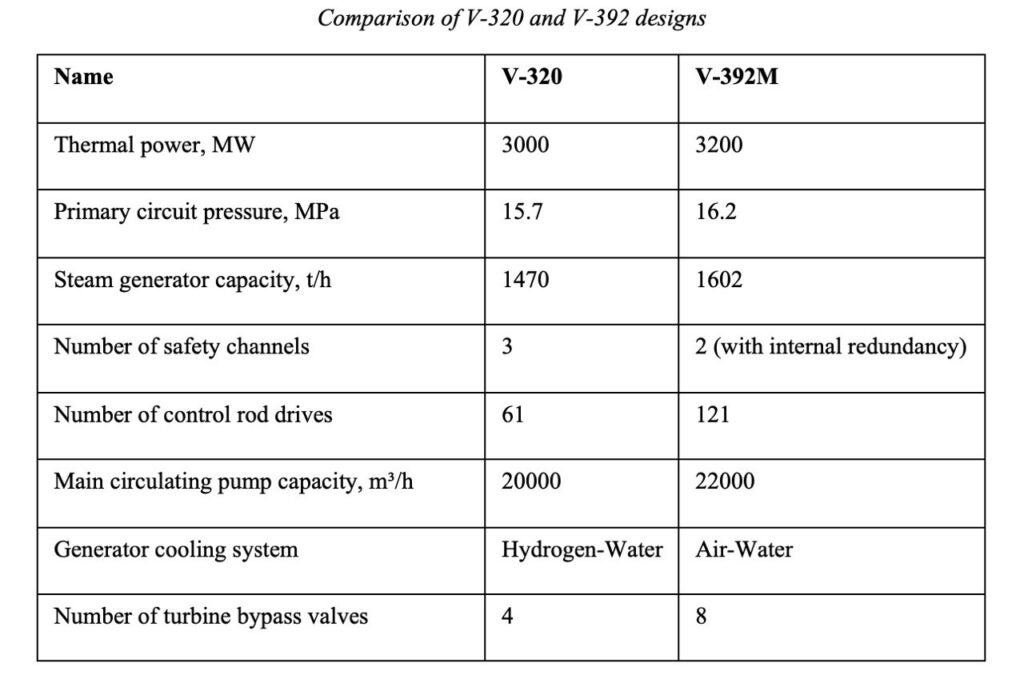

Among the main changes introduced in the V-392M design compared to the serial Soviet V-320 design were the following:

- Improved nuclear and physical properties of the reactor core.

- Negative reactivity coefficients ensured across a wider range of technological parameters.

- New automated systems for equipment monitoring and diagnostics.

- Improved neutron and radiation monitoring systems for the core.

- Extended service life of the main reactor equipment to 60 years.

- Increased maximum fuel burnup to 70 MW·days/kg.

- Reduced downtime and improved capacity factor (CF).

The V-392M design also adopted the most effective solutions from the China and India VVER-1000 designs: a double containment, a core melt retention device (core catcher), a passive heat removal system from steam generators, a passive core flooding system with second-stage hydro-accumulators, and several others.

Furthermore, the V-392M and subsequent VVER-1200 designs incorporated lessons learned from the Fukushima-1 accident in Japan. Measures included enhanced provisions for mobile equipment (mobile pumping units and diesel generators), improved heat removal from the spent fuel pool, and more.

The entire concept of monitoring unit parameters and associated protections underwent major changes. For example, while the V-320 design (Rostov NPP Unit 3) included 3,686 protections and interlocks and 6,238 measurement channels, the V-392 design features 11,140 protections and interlocks and 12,081 measurement channels.

Overall, the VVER-1200 design can be described as an evolutionary development of high-capacity VVER technology. By preserving time-tested fundamental design and engineering solutions while introducing carefully validated innovations, the design was able to transition directly from the first-of-a-kind unit to serial construction, ensuring that Rosatom had a Generation III+ high-capacity pressurized water reactor design in its portfolio.

Toward Two-Component Nuclear Power

Rosatom’s nuclear power development strategy requires VVER designers not only to continue evolutionary improvements of high-capacity reactors, but also to develop systems that can truly be considered innovative. One such design, approved for deployment, is the VVER-S-600.

The first task of this new design is fairly straightforward—it will be a medium-power unit intended to meet a range of energy needs in Russia. It may also attract foreign customers with relatively modest demand or underdeveloped electrical grids.

The second task, hidden behind the “S,” is more interesting. The new reactor will employ the principle of spectral shift control, which has never before been implemented commercially worldwide.

Two-component nuclear power envisions a system where both thermal and fast reactors operate together in a closed fuel cycle. Since thermal reactors, by their physical nature, cannot produce more nuclear fuel (plutonium) than they consume (i.e., their breeding ratio is below one), the overall system requires fast reactors with a breeding ratio above one to ensure sustainable fuel supply.

For current thermal reactor designs such as the VVER, the breeding ratio can be roughly estimated at 0.5. This is a very rough approximation, but it highlights the problem: to achieve an overall system breeding ratio of at least one (so that the system efficiently uses all mined uranium without requiring external uranium-235 feed), engineers must either significantly increase the breeding ratio of fast reactors, which is technologically challenging, or raise the share of fast reactors in the system.

The issue can be mitigated by developing a VVER design with a higher breeding ratio. Neutron physics provides the answer: uranium-238 has a giant resonance capture cross-section at neutron energies of about 6.5 eV. By slightly under-moderating neutrons in a VVER, they are more likely to hit this resonance, increasing neutron captures by uranium-238 nuclei and producing plutonium-239 … in other words, raising the breeding ratio.

Simply reducing the water content in the VVER core to achieve under-moderation is not an option, as this would adversely affect the negative void reactivity coefficient, reducing it or even making it positive. A promising solution is the use of displacers—special rods embedded into fuel assemblies that can regulate the uranium-to-water ratio by displacing water from the core, thereby affecting neutron moderation and the resulting spectrum in the reactor. Rosatom designers propose to implement this method of spectral shift control in the VVER-S-600 design.

It is still too early to say exactly what improvement in breeding ratio the VVER-S-600 will achieve compared to the VVER-1000/VVER-1200. The first VVER-S-600 unit is expected to be built and commissioned at the Kola NPP in the mid-2030s.

The appearance of the VVER-S-600 as a medium-power reactor will complete Rosatom’s lineup of light-water reactors available for domestic and international customers. The lineup already includes the proven VVER-1000 and VVER-1200 for high-capacity applications; the VVER-S-600 for medium-power; and, at the small end, the VVER’s distant relative—the RITM icebreaker reactor. This means, among other things, that the VVER technology will retain its fundamental significance for Rosatom and continue serving society well into its second century.

—Alexander Uvarov is director of AtomInfo, an independent Moscow-based think tank.