|

In Brazil’s industrial heartland, a pioneering energy project has earned a POWER Top Plant award for turning hydrogen-rich waste into clean, reliable power. The Vesta Cogeneration Plant not only boosts efficiency at Latin America’s largest petrochemical complex, it also sets a new benchmark for energy innovation in the chemical manufacturing sector.

In the heart of industrial São Paulo, where Brazil’s first petrochemical complex hums with near-ceaseless production, a seemingly paradoxical challenge emerged: How do you transition toward cleaner energy when your manufacturing process generates hydrogen-rich waste gas as a byproduct? For most companies, this excess gas would simply be flared off—a wasteful practice that releases emissions without capturing value. But Braskem, the largest thermoplastics producer in the Americas, saw an opportunity where others might not. Its vision and answer to the dilemma was the Vesta Cogeneration Plant, a modernization project that proves that the path to sustainable manufacturing doesn’t always require abandoning existing infrastructure. Instead, it sometimes means finding ingenious ways to harness the chemistry already happening within your processes.

The ABC Petrochemical Complex

The ABC Region in São Paulo, Brazil, refers to an industrial metropolitan area composed originally of three cities: Santo André (A), São Bernardo do Campo (B), and São Caetano do Sul (C). These three cities form a major industrial hub south of São Paulo city and are renowned for their significant automotive, petrochemical, and metallurgical industries.

Opened in 1972, the ABC region’s raw material plant was part of the first petrochemical complex to begin operations in Brazil. Installed in Santo André, the unit is responsible for transforming raw materials originating from petroleum, such as naphtha, into basic chemicals such as ethylene, propene, butadiene, and hydrocarbon resins, which are the basis for various materials, such as plastic, used in segments such as construction, the automotive industry, hospital hygiene items, the food sector, packaging, clothing, and footwear.

In February 2019, Braskem decided to partner with Siemens Energy to retrofit the ABC Petrochemical Complex. The project, intended to modernize the energy system, was expected to provide greater efficiency in production and improvements to Braskem’s sustainability indicators at the complex. The technological update would serve the cracker, the main industrial unit of the petrochemical complex, responsible for the production of raw materials for the chemical and plastic sectors. As such, it wasn’t just installing new equipment—it was pioneering a model for how energy-intensive industries could turn their waste streams into competitive advantages.

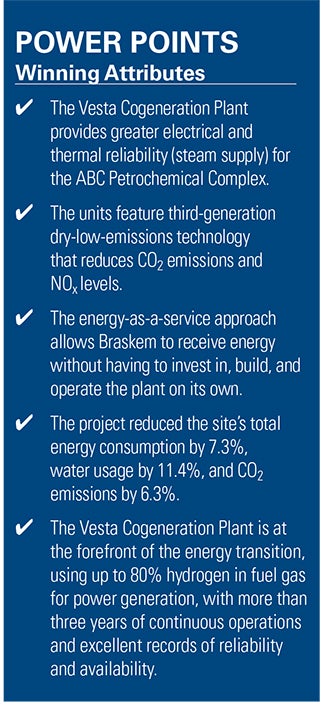

“This project is an example of the great efforts employed by Braskem in the search for greater operational excellence, in addition to reinforcing our commitment to sustainable development,” Luís Pazin, Chief Industrial Officer of the Braskem Chemicals unit in the Southeast region, said when the project was announced. “With the combined cogeneration of electricity and gas, we will consume less energy and emit even fewer greenhouse gases.” Notably, the company estimated it could reduce the unit’s water consumption by 11.4% and CO 2 emissions by 6.3% as a result of the project.

“The cogeneration was prioritized by Braskem at their industrial plant because it was completely aligned with its energy efficiency goals,” Andre Colen Carrasco, head of Operations and Maintenance (O&M) and Services for Siemens Energy in Brazil, told POWER. “The cogeneration made it possible to reduce the site’s total energy consumption by approximately 7.3%, while also increasing the reliability of the electricity supply. With that, Braskem became more competitive in production costs, and reduced production losses related to problems in external electricity supply, while improving environmental impacts.”

Do What You Do Best

Siemens Energy was responsible for implementation of the project, and for operating the electric and steam cogeneration plant for an initial term of 15 years. As part of the contract, Siemens agreed to implement a fully integrated and redundant equipment solution, including two SGT-600 gas turbines, an E-house (that is, a ready-made electrical building that houses all the necessary power distribution and control equipment), as well as an extension of the existing high-voltage substation, three reciprocating compressors, an advanced load-shedding system, and associated software for plant control. The plant’s state-of-the-art technology solutions combined high energy efficiency and extreme operational reliability with low emissions. These elements were part of an energy-as-a-service concept, meaning Braskem receives the energy without having to invest in, build, and operate the plant on its own.

“Braskem’s confidence in defining Siemens as a strategic partner for this challenging project is a result of our technological and operational capability, which coupled with the attractiveness of the innovative BOO (build, own, and operate) model, ensures that Braskem can focus its resources on the business, leaving Siemens with the responsibility for making the necessary investments in the engineering, implementation, operation, and maintenance of the cogeneration plant,” Yuri Sanches, general manager with Siemens Energy in Brazil, said when the project was rolled out.

Yet, the collaboration went beyond Braskem and Siemens Energy to other companies based in the region. “We established partnerships with several local suppliers and contractors to source materials and services. This not only supported the local economy but also ensured access to expertise familiar with the regional context,” Carrasco explained. “Additionally, we collaborated with local educational institutions to provide training and development opportunities for the workforce involved in the project. The EPC [engineering, procurement, and construction] company, which has extensive experience in power plants, executed the project and is based in São Paulo, the same state as Braskem Petrochemical.”

Getting the Job Done

Construction was initiated in 2020 and completed in mid-2022. Throughout the construction phase, Siemens Energy maintained a strong safety record, with no major incidents reported. At the peak of construction, it had approximately 350 workers onsite, all adhering to strict safety protocols to ensure a safe working environment. No personnel accidents have been reported since the start of commercial operation on Aug. 1, 2022, either, thus continuing the stellar safety performance at the site.

Renato Mendes, plant manager of the cogeneration plant, said one of the primary challenges for the project was ensuring compatibility between the SGT-600 turbines and the existing petrochemical facility infrastructure. “This involved addressing the variations in the gas composition and ensuring that the turbines could operate efficiently with the residual process gas containing high hydrogen content,” he explained. “There are several streams of process gases, with different compositions and natural variations. Consequently, the turbines need to be able to cope with the predicted range in which they are likely to operate. Additionally, we had to manage the integration of advanced control systems to optimize performance while minimizing disruptions to ongoing operations.”

Construction took place while the petrochemical plant was in operation. The area granted on loan for the cogeneration plant is inside Braskem’s site and adjacent to the petrochemical operations. The connections between the units and the Braskem plant were completed during a general maintenance shutdown, under strictly limited deadlines. This required a meticulously planned schedule for system interconnections.

Other important challenges involved electrical integration and maintaining operational stability at all times. The petrochemical complex was operating its existing electrical and steam systems during some commissioning activities, which complicated the process. One decision that was made during the design phase, which turned out to be crucial for success, was placing the cogeneration operational control stations inside Braskem’s main operational control center. This allowed Siemens Energy and Braskem operating teams to communicate in real time and stay aligned.

Hydrogen: Impetus for the Project

As previously mentioned, many industrial processes, such as those in petrochemical complexes or refineries, can produce hydrogen as a byproduct. Using this hydrogen as an alternative fuel to natural gas can be economically attractive. Many sites with similar setups use process gas to generate heat and steam. However, an even more efficient option for the process plant would be to extend the use of hydrogen-rich residual gas to produce electricity as well. “As industries are decarbonizing, using residual process gases with hydrogen content can play a key role in chemical and petrochemical industries and refineries in various regions of the world,” Carrasco noted.

As previously mentioned, many industrial processes, such as those in petrochemical complexes or refineries, can produce hydrogen as a byproduct. Using this hydrogen as an alternative fuel to natural gas can be economically attractive. Many sites with similar setups use process gas to generate heat and steam. However, an even more efficient option for the process plant would be to extend the use of hydrogen-rich residual gas to produce electricity as well. “As industries are decarbonizing, using residual process gases with hydrogen content can play a key role in chemical and petrochemical industries and refineries in various regions of the world,” Carrasco noted.

The maximum power output of an SGT-600 turbine is 24 MW. For this application, each turbine provides 19 MW of power continuously and 80 tons per hour of steam to the petrochemical complex through its heat recovery steam unit (HRSU). In addition, the gas turbines feature third-generation dry-low-emissions (DLE) technology. The DLE technology reduces CO 2 emissions, and NO x levels from the turbines are low at just 25 parts per million (ppm). A load-shedding system ensures safe operation of the plant by managing all loads depending on the available power supply.

“The third-generation DLE combustion technology has been developed and validated ahead of the release in the Vesta project for hydrogen levels up to 80%,” Mendes reported. “Only minor adjustments in the control system were needed to handle the sometimes fast and high variations in the hydrogen content during disturbances in the fuel gas supply.”

The Vesta Cogeneration Plant gives clear proof to other industries in Brazil and around the world that this business model works. Besides the long-term sustainability of the plant and its high efficiency, the project also demonstrates the advantages of the “energy-as-a-service” approach that covers the entire value chain. “Siemens Energy built, owns, and operates the cogeneration plant for 15 years. This addresses customer needs in reliable and secure operations while at the same time resulting in capital expenditure savings,” touted Carrasco. “This has come without a price increase and while significantly reducing the petrochemical giant’s exposure to grid failures.”

The project is also aligned with Braskem’s goals of reducing Scope 1 and 2 greenhouse gas emissions by 15% by 2030 and achieving carbon neutrality by 2050. Clearly, the Vesta Cogeneration Plant is a winner, not only for the complex, but also for a POWER Top Plant award.

—Aaron Larson is POWER’s executive editor.