corrosion

-

O&M

Fighting Corrosion, Scale, and Salt Buildup in Critical Turbines

Turbines play an integral role in power production, turning steam into mechanical energy that generates electricity. Though large and powerful, these dynamic pieces of equipment are also vulnerable and must be

-

O&M

How to Prevent Oxygen Pitting in Boilers: A Safer Alternative to Hydrazine

Experienced boiler operators know that oxygen can cause localized, severe corrosion in steam boiler systems through a process called oxygen pitting. This occurs when dissolved oxygen in the water comes into

-

O&M

Fighting Scale and Corrosion on Balance of Geothermal Plant Equipment

There are three main types of geothermal power plants: dry steam plants that send geothermal steam directly from the ground into the turbine, flash steam power plants that convert hot groundwater to steam

-

Waste to Energy

Maximizing Corrosion Prevention in Waste-to-Energy Plants

Waste-to-energy (WtE) facilities have the potential to become one of the most sustainable and reliable forms of energy creation on the planet, but they have their challenges. The most eco-conscious way of adopting WtE is by repurposing fossil fuel plants and retrofitting them for burning and transforming biomass. Whether working with old or new mechanisms, […]

-

Power

Tips for Managing Steam and Water Analysis System Maintenance in Aging Plants

Proper steam and water analysis system (SWAS) maintenance is critical to the operation of any coal, nuclear, or combined cycle power plant, many of which are being forced to ask more of aging equipment. For

-

O&M

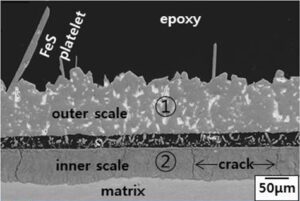

Corrosion Research Leads to Material Improvements and More Reliable Systems

Fossil-fueled power plants are billion-pound investments that businesses (as well as whole nations themselves) around the world can’t afford to simply discard. Yet, the combinations of old plant, new fuels, and new operating conditions lead to corrosion, faults, downtime, and inefficiencies for plant operators and manufacturers. But these kinds of bridging technologies—between the “black” and […]

-

O&M

The Added Value of Corrosion Protection for Pump and Valve Maintenance

Power plants depend on hundreds of valves and many different pumps to carry out operations 24/7. Good maintenance procedures—including routine tasks and predictive maintenance—are critical to keeping these

-

O&M

Developing Coatings for Use in Harsh Biomass Combustion Environments

Corrosion is a constant battle for infrastructure of all kinds—the natural response of materials like metals to their environment, causing damage to everything from turbines to oil pipelines and vehicles. The costs are vast. A National Association of Corrosion Engineers (NACE) IMPACT study published in 2013 claims that corrosion causes damage valued at $2.5 trillion […]

-

O&M

How to Defeat Dew Point Corrosion in Heat Recovery Steam Generators

The experience of South Humber Bank Power Station in the UK is just one example of overcoming corrosion challenges at power generation facilities. Facing issues during routine maintenance shutdown of heat recovery steam generators (HRSGs), South Humber began using VCI (Vapor Corrosion Inhibitor) technology to solve their dew point corrosion problem in 2009. Although it […]

-

Press Releases

Reduce Your Concrete Carbon Footprint while Enhancing Concrete Durability!

Concrete is the world ’s most widely used construction material—and also one of its greatest contributors to greenhouse gas. The root cause is cement production, which alone accounts for approximately 8% of global CO2 emissions. At this rate, successful strategies to lower concrete carbon output are especially significant. MCI® Technology is one of those simple […]

-

Fuel

Protecting Land-Based Diesel Assets from Risks Associated with Biofuels

Greenhouse gases (GHG) are a global issue. As the planet warms, we need to find any way we can to lower carbon footprints. For the future, there are many projects working to find zero-carbon solutions using new energies, but, while we wait for these developments and the necessary infrastructure to support this energy transition, we […]

-

O&M

Water, Heat, Metal: A Crucial and Difficult Dance

Proper water chemistry has always been important for dependable steam plant operation, but it may be even more critical today due to changes in operating routines and increased plant cycling. Failure not only

-

Press Releases

VpCI®-337 – An Easy Alternative to Nitrogen Purge for Void Space Layup!

Is there an easy way to prevent corrosion inside void spaces of idle equipment or permanent structures? This is a major need, primarily in the oil and gas industry but also in any industry that deals with metal tanks, piping, boilers, heat exchangers, hollow metal structures, or even hard-to-reach areas between the layers of metal […]

-

O&M

Getting Ahead of Costly Heat Exchanger Failures in the Power Generation Industry

Heat exchangers are important in all thermal power plants and in many other applications. If not properly operated and maintained, a variety of failures can occur, resulting in downtime, reduced efficiency

-

News

Advantages of Dual Linear Array Probes for Corrosion Inspection

The power generation industry is among those whose aging infrastructure contributes to increased safety concerns, and can lead to costly unscheduled maintenance and shutdowns. Facilities must be vigilant about

-

News

HVTS Stops Alloy 625 Weld Overlay Corrosion in Waste-to-Energy Boiler

A boiler at the Renergia waste incineration plant in Perlen, Switzerland, was experiencing fireside corrosion. The shop-applied Alloy 625 weld overlay was showing signs of premature accelerated degradation

-

O&M

Changes in Boiler Operations Bring Innovations in Erosion and Corrosion Protection

Metal loss of the pressurized tubes inside the boiler is a big concern for boiler designers and operators. Changing fuel composition and other service parameters can lead to accelerated erosion and corrosion

-

News

Equipment Showcase: Coatings and Corrosion Control

A major part of maintaining a power plant at peak efficiency is dealing with or preventing damage from corrosion and corrosive objects that can enter air and water intake systems, including pipes and fluid

-

News

PVD Coatings Extend Life of Gas and Steam Turbine Components

Industrial gas turbine (IGT) manufacturers and maintenance, repair, and overhaul (MRO) personnel are continually seeking new ways to improve the performance and longevity of critical components. High-value

-

News

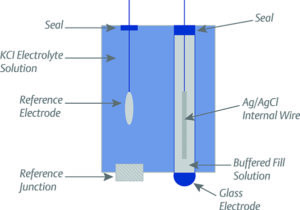

High-Purity Boiler Water pH Measurement

Water quality monitoring and control are two of the most critical operations that power plants employ to protect assets, such as boilers and steam turbines, from corrosion by assuring the correct addition of

-

Press Releases

Equipment Showcase: Instrumentation and Control

The equipment showcase section includes products from a variety of vendors that serve the power generation industry. POWER magazine will feature a different power-related equipment category in several issues

-

O&M

A Primer on Gas Turbine Failure Modes

When a gas turbine goes down, recovery can be an expensive, time-consuming process. Knowing what can go wrong and how to anticipate turbine failures can help you avoid a difficult unplanned outage. Gas-fired power is hot and getting hotter. The Energy Information Administration estimates that 2016 will be the first year ever that the U.S. […]

-

O&M

Load Cycling and Boiler Metals: How to Save Your Power Plant

As many coal-fired power plants designed for baseload service are asked to cycle, unforeseen stresses have been introduced to boiler pressure parts. Understanding the effects and implementing mitigation strategies could prevent premature component failure and keep facilities operating reliably. On August 3, 2015, the U.S. Environmental Protection Agency finalized the Clean Power Plan, which calls […]

-

O&M

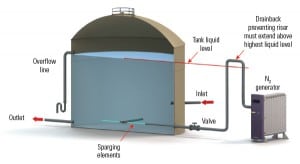

Prevent Contamination and Corrosion in Demineralized Water Storage Tanks Using Nitrogen Sparging and Blanketing

The electric power generation industry relies heavily on demineralized and deionized water during process operations. Managing the water supply is critical not only under normal operating conditions, but also during outages. When scheduled or unscheduled outages occur, many boiler and pre-boiler systems are drained. After the outage, they are refilled with water that has been […]