Focus on O&M

-

O&M

Automated Tools Improve Hydroblasting Productivity and Safety

Just a decade ago, a hydroblasting contractor was considered cutting-edge if he owned a spinning nozzle for his shotgun and a 2-D tank cleaning tool. Now, the next evolution in hydroblasting technologies is

Tagged in: -

O&M

Electric Co-op Shines a Light on Rack Selection

Clay Electric Cooperative was determined to dramatically improve its logistics, reliability, and productivity, even before the Florida member-owned utility set out to build a new warehouse to consolidate

Tagged in: -

O&M

Special Flooring Considerations for Mission-Critical Facilities

Every element in the construction and operation of power generation plants must be considered to keep such mission-critical facilities running around the clock. The proper flooring can contribute not only to

-

O&M

Taking Visual Inspection Technology to a New Level

When many of us pick up our smartphones and take a panoramic photo, we probably think that’s a neat feature. But for inspection personnel at a nuclear energy facility, the technique behind those panoramic

-

O&M

Software Helps with Proactive Maintenance

Utilities and power plant equipment providers know that maximizing the value of their assets includes keeping them maintained and online. Minimizing downtime is critical, certainly when it comes to keeping the

Tagged in: -

O&M

How the Internet of Things May Help Power the Future

Utility poles are the literal backbone of the electric utility industry. With an estimated 180 million or more in the nation’s power grid, it’s not hard to imagine the monumental task associated with

-

O&M

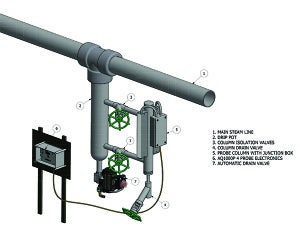

Replacement Instruments Improve Turbine Water Induction Protection

Turbine water induction protection systems are designed to keep water out of the turbine and prevent damage. Steam turbine damage from water induction is a costly economic, safety, and reliability concern. Any

Tagged in: -

Connected Plant

Seven Software Tools for Energy Managers

There are many tools available to assist companies as they gain a better grasp on how their energy is being used, and what that means for the goal of efficient energy management. Not all solutions are created

-

O&M

Collaboration and Innovation Drive Retrofit Success at Plant Barry

The James M. Barry Electric Generating Plant, both a coal-fired and natural gas-fired facility in Bucks, Alabama, sits on the west bank of the Mobile River. The facility’s coal is delivered via the river

-

O&M

Parts Exchange Program Saves Money, Keeps Xcel’s Turbine Fleet Spinning

Keeping combustion turbines spinning at power plants across Xcel Energy’s service territory is critical to maintaining reliability and minimizing costs. One of the challenges to meeting that goal is