Features

-

Coal

New coal plant technologies will demand more water

Population shifts, growing electricity demand, and greater competition for water resources have heightened interest in the link between energy and water. The U.S. Energy Information Administration projects a 22% increase in U.S. installed generating capacity by 2030. Of the 259 GW of new capacity expected to have come on-line by then, more than 192 GW will be thermoelectric and thus require some water for cooling. Our challenge will become balancing people’s needs for power and for water.

-

Nuclear

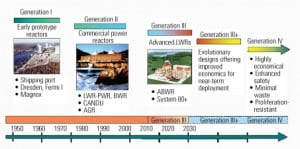

Developing the next generation of reactors

Dozens of intrinsically safe Generation III+ reactors are expected to be deployed in the U.S. in the coming years. Today, scientists already are looking over the horizon to Generation IV reactors that will be capable of producing hydrogen and process heat as well as electricity while generating much less radioactive waste.

-

Instrumentation & Controls

Turbine technology maturity: A shifting paradigm

Selecting the right turbine(s) for a specific power project is a complex process that poses two challenges. One is understanding which field experience cited by suppliers represents proven technology; the other is evaluating whether a turbine upgrade represents an evolutionary change or a revolutionary transformation that warrants further study before deploying it in the field. Here‘s how a leading EPC contractor makes technology-neutral equipment selection decisions on behalf of its customers.

-

Instrumentation & Controls

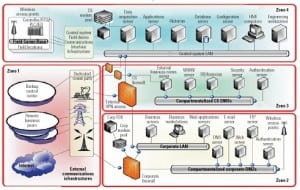

Time to get serious about security

Managing ongoing threats to power plants’ digital, telecommunications, monitoring, control, and automation systems is no longer just a good idea. It’s an essential element of superior plant operations and now a regulatory requirement as well, thanks to new critical infrastructure protection standards recently approved by FERC.

-

O&M

Extend EOH tracking to the entire plant

Predicting combined-cycle system longevity and determining optimal maintenance intervals at the same time is difficult: It requires balancing repair costs against the risk of trying to squeeze that last bit of life out of some component before it fails. One solution to the problem is to extend coverage of an equivalent operating hours (EOH) preventive management program for turbines to the entire plant.

-

Business

ELECTRIC POWER celebrates 10th anniversary in Baltimore

At this juncture our industry is faced with greater uncertainty and opportunity than ever before. That’s why you won’t want to miss all the information, ideas, and networking available at the power generation industry’s premier event in May.

-

O&M

Maintaining water sample panels improves plant availability

Even comedian Rodney Dangerfield got more respect than many plant water sample panels do. But power plants ignore sample panels at their peril. Those sample panels, and readings of the on-line analyzers they support, identify when multi-million-dollar systems have a problem that demands immediate attention.

-

Instrumentation & Controls

Wireless technologies connect two LCRA plants

Lower Colorado River Authority recently put two separate plants at its Lost Pines Power Park under one functional management system. The project has already deployed a layered wireless infrastructure that allows the two plants to communicate at a fraction of the cost of a wired solution while providing a platform for optimizing work processes and reducing operating costs. What’s not to like?

-

O&M

Desuperheating valves take the heat

Hot reheat steam bypass actuators are some of the most critical, yet least understood components in a typical combined-cycle plant. If you’re using pneumatic actuators to stroke your main steam or hot reheat bypass valves in a cascading bypass system, you’re behind the times. Here’s a way to get better control of the bypass process, shorten unit start-up and train blending times, and decrease your plant’s heat rate—all at the same time.

-

Water

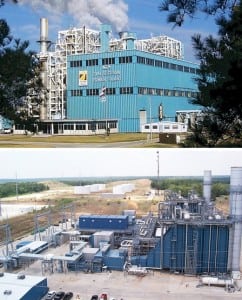

Benefits of evaporating FGD purge water

In the U.S. and the European Union, scrubbers are installed on all new coal-fired power plants because their technology is considered the best available for removing SO2. A zero-liquid-discharge system is the best technology for treating wet scrubber wastewater. With the future promising stricter limits on power plants’ water use, ZLD systems that concentrate scrubber purge streams are sure to become as common as ZLD cooling tower blowdown systems.