At a time of surging demand for electric energy, the power industry has to ensure reliable and stable supply with the flexibility needed to handle intermittent wind and solar generation. Through production, transmission and distribution, a key factor in maintaining this balance is effective control and automation, supported by capable and reliable field equipment.

At a time of surging demand for electric energy, the power industry has to ensure reliable and stable supply with the flexibility needed to handle intermittent wind and solar generation. Through production, transmission and distribution, a key factor in maintaining this balance is effective control and automation, supported by capable and reliable field equipment.

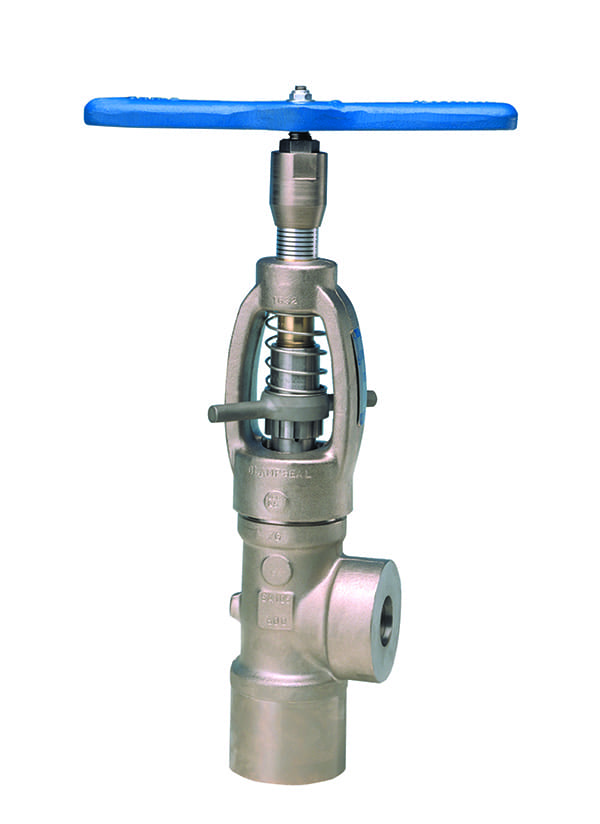

In a world of large power plants – whether thermal, hydro, wind or solar – it’s easy to overlook the role of components such as valves and actuators. Yet from cooling circuits to feedwater treatment, from gas turbine fuel supply valves to the penstocks of hydropower plants, our industry relies on valves and actuators.

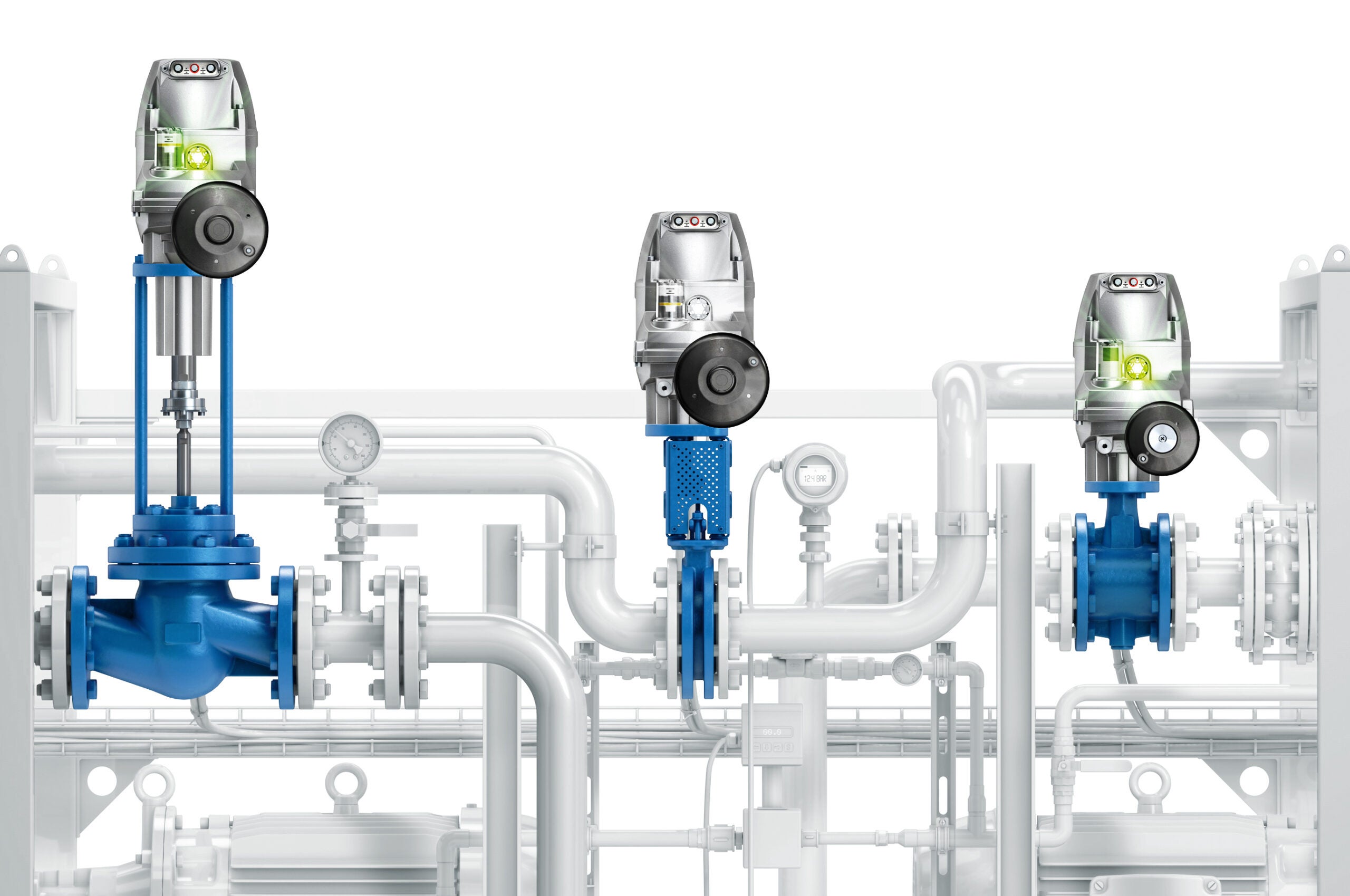

Modern, smart electric actuators such as the PROFOX series combine quick, precise positioning and control with high reliability, powerful digital functions, flexible installation and operation, physical compactness, and low energy consumption. Wherever the flow of liquids or gases needs to be controlled, electric actuators keep the power industry on track.

Versatile shape-shifters

The PROFOX series from AUMA is a modern, intelligent actuator platform that supports efficient, sustainable energy generation through a combination of compact design and smart features. The versatile PROFOX series includes multi-turn, part-turn, and linear actuators, offering automation solutions for all valve types in the lower torque and thrust ranges. An explosion-proof version, PROFOX X, has ATEX and IECEx certifications for the highest gas group IIC T4, which includes hydrogen. Operating costs are low, thanks to high mechanical efficiency and low standby consumption. The range covers:

- part-turn actuators (32– 600 Nm)

- multi-turn actuators (10–100 Nm)

- linear actuators (0.8–18 kN)

PROFOX actuators show their strengths in a wide range of flow control applications in all types of power plants, including for example cogeneration, district heating and cooling and hydropower plants.

High-precision flow control

Wherever reliable and precise valve control is required, PROFOX actuators are in their element thanks to their high positioning accuracy. Their variable-speed DC motors ensure fast and precise valve positioning, enabling sophisticated closed-loop control applications. Thanks to configurable speed profiles, motor speed can be optimised for best control response over a wide range of process dynamics. Control parameters can easily be adjusted locally or remotely, ensuring that processes run optimally at all times.

Easy integration and operation

Small size, a wide range of mounting options, easy installation and commissioning in just a few steps make PROFOX actuators easy to integrate in both existing and new plants.

For on-site staff dealing with many different field devices every day, their easy and intuitive operation is a game-changer. PROFOX actuators can be configured and operated via a smartphone app or a dedicated remote control. This saves time and cost in the everyday life of any power plant, and is especially advantageous when actuators are installed in positions that are hard to access, for example in pits or at height.

Data analysis for plant reliability

PROFOX actuators make it easy to leverage the potentials of digitalisation, as they include intelligent sensors, extensive data logging capabilities and flexible communication interfaces. Data logging covers a huge range of operational data such as number of motor starts, motor run time, temperatures, and events such as warnings. AUMA provides advanced digital tools to analyse actuator log data and identify maintenance requirements as well as potential to optimise process parameter settings. Taking preventative and corrective measures in time helps avoid unplanned downtime.

Interfaces for every requirement

AUMA’s PROFOX actuators come with future-proof communications interfaces for every requirement, from simple I/O to fieldbus and Industrial Ethernet. This ensures perfect integration into power plant control processes and accommodates future control system upgrades. For example, PROFOX actuators offer direct Profinet integration, including redundancy options.

When sustainability counts

Electric actuators support the need for sustainability and lower plant operating costs. Unlike pneumatic actuators, which need a constant supply of compressed air, electric actuators only consume significant energy when they are actually moving. AUMA’s PROFOX actuators go a step further, being specifically designed for low energy consumption, including during standby. With dozens or hundreds of actuators on a site, power savings are significant.

No fear of downtime

Thanks to their high-quality, “made in Germany” design and construction, wide operating temperature range and advanced corrosion protection, PROFOX actuators have long service lives. Needing only minimum maintenance throughout their long product lifecycle, they conserve resources and cut the total cost of ownership.

An HVDC converter platform on an offshore wind farm, for instance, typically employs up to 800 PROFOX actuators, mainly in the cooling system. In such a demanding environment, where the cost of access for maintenance can be very high, the extreme reliability of PROFOX actuators is a key advantage. The ability to monitor and control the actuators remotely, and their powerful data collection functions, also bring significant operational benefits in remote locations.

In conclusion

Smart electric actuators play a key role in securing reliable and sustainable energy generation, transmission and distribution. AUMA’s versatile and reliable PROFOX actuators meet the challenging requirements of modern power plant automation through:

- modulating duty with high positioning accuracy

- easy and flexible integration

- powerful digital functions

- ergonomic daily operation

- reliability and long service life

- excellent price/performance ratio

Learn More at profox.auma.com