The landscape of power generation has been evolving for some time, but the rate at which this is occurring appears to be accelerating. Numerous factors contribute to this (concerns with impacts on climate, increasing power demands – artificial intelligence and data centers, intermittent energy sources and grid stability, new technologies, etc.) but at the end of the day, the objectives for power generators are similar to what they have always been, but are ever more crucial:

● Maximize Productivity

● Maximize Reliability

● Minimize Costs

● Minimize Unexpected Circumstances

Continually realizing these objectives within the evolving landscape is the question essentially everybody is asking. For instance,

● How do we improve our unit turndown?

● How can we ramp faster while maintaining or improving stability?

● What can we do to stay near the top of the dispatch order?

● Can we decrease our chemicals cost?

● How near failure is that pump or motor? Does it need maintenance?

● Is there a better way to operate so that we’re really optimized all the time?

● How could we better track and report on our day-to-day operations as well as special events?

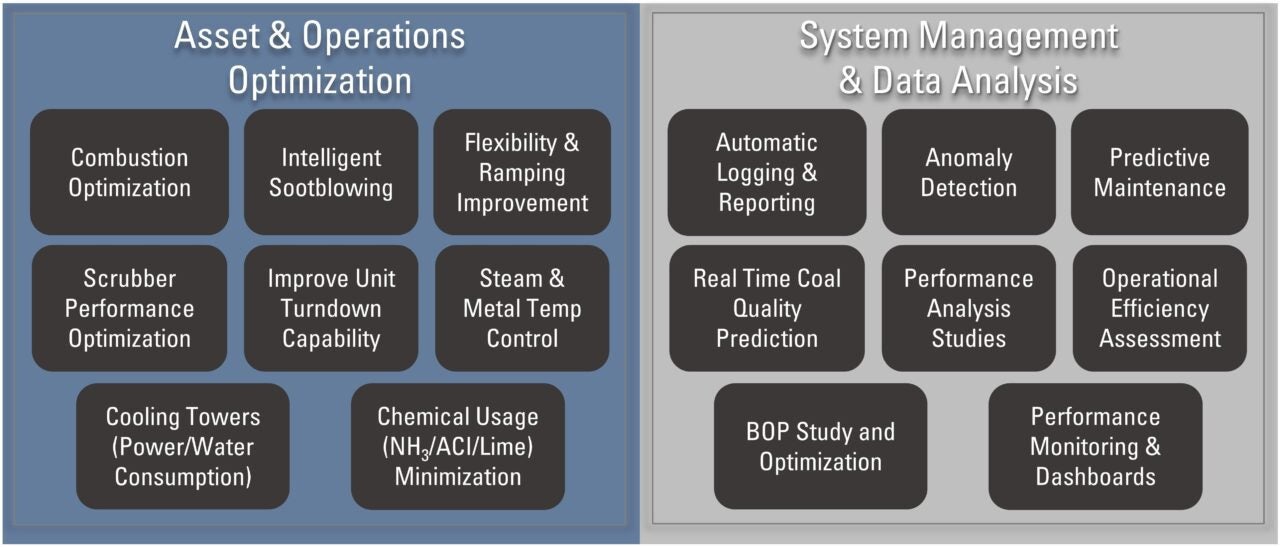

Getting the most out of a process and system with minimal input can be challenging, but this has never been more achievable with Taber International’s unparalleled partner approach to Customized and Adaptable Automation & Optimization. Taber develops entirely unique and customized systems to integrate with your existing process and system, focused fully on your specific objectives.

The challenge is achieving objectives, goals, and organization targets & KPIs that are often inherently contradictory. Taber’s approach is to be a partner on this journey; utilizing the breadth of automation, controls, artificial intelligence, data analytics, digital tools, and real-world engineering expertise to tease out synergies and optimal methods to achieve each site’s goals, accounting for their unique circumstances.

The result is two-fold:

- A system and framework that understands and responds to the intricacies of your process, is built directly to account for these conditions, and automates and optimizes individual aspects of the system in real-time to constantly and continually enhance all the elements of your process simultaneously.

- A partnership where the clients needs and goals are always paramount and the team has the technical knowledge and resources to make the most of all that’s available by any means available, continually expanding and advancing toward additional gains & improvements at minimal client cost.

Immediate & Ongoing Benefits Where YOU Need Them

Taber’s approach is fully client-centric, focused entirely on addressing your major process & business goals while also incorporating day-to-day problems within the optimization framework. From day one, Taber works with clients to identify process improvement opportunities and gets started constructing applications to make these improvements reality.

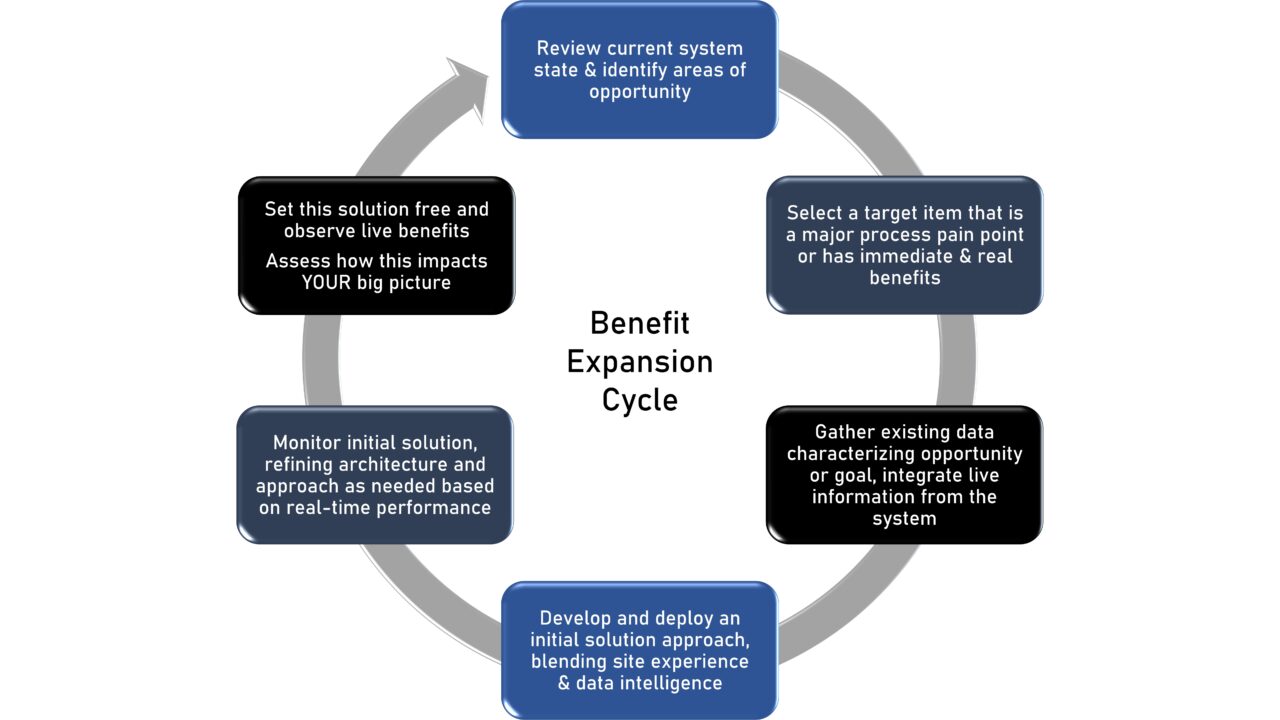

The process is really quite simple, but when executed between professionals and experts, substantial gains are readily achieved. When operating as partners focused on the client’s overall goals, these gains are repeated again and again at multiple levels and stages of the process, compounding benefits. Further, Taber trains the client’s personnel in the techniques and systems Taber uses, so that they can provide their own upkeep and expansion. This eliminates the “black box” system and makes this a truly powerful tool for the client. In many circumstances, a complete revolution of this cycle takes less than one month, enabling benefits to be achieved at numerous points across the system, continually extending improvements.

Real-World Tested and Proven

Taber has been successfully utilizing this partner approach for nearly two decades and is proud to state that 100% of clients have continued as partners, working together to identify new areas for improvement & optimization and deploying advanced systems & tools. The experiences of most clients are similar, but one case in particular demonstrates the full potential of the Benefit Expansion Cycle.

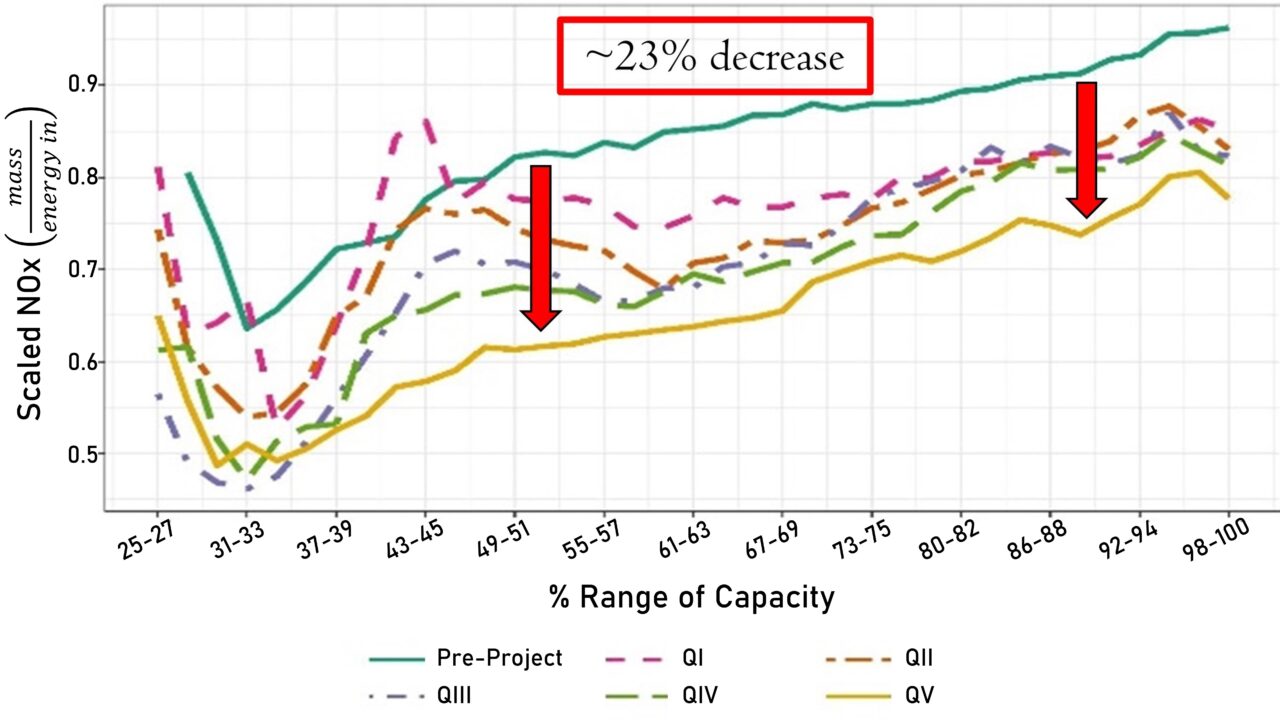

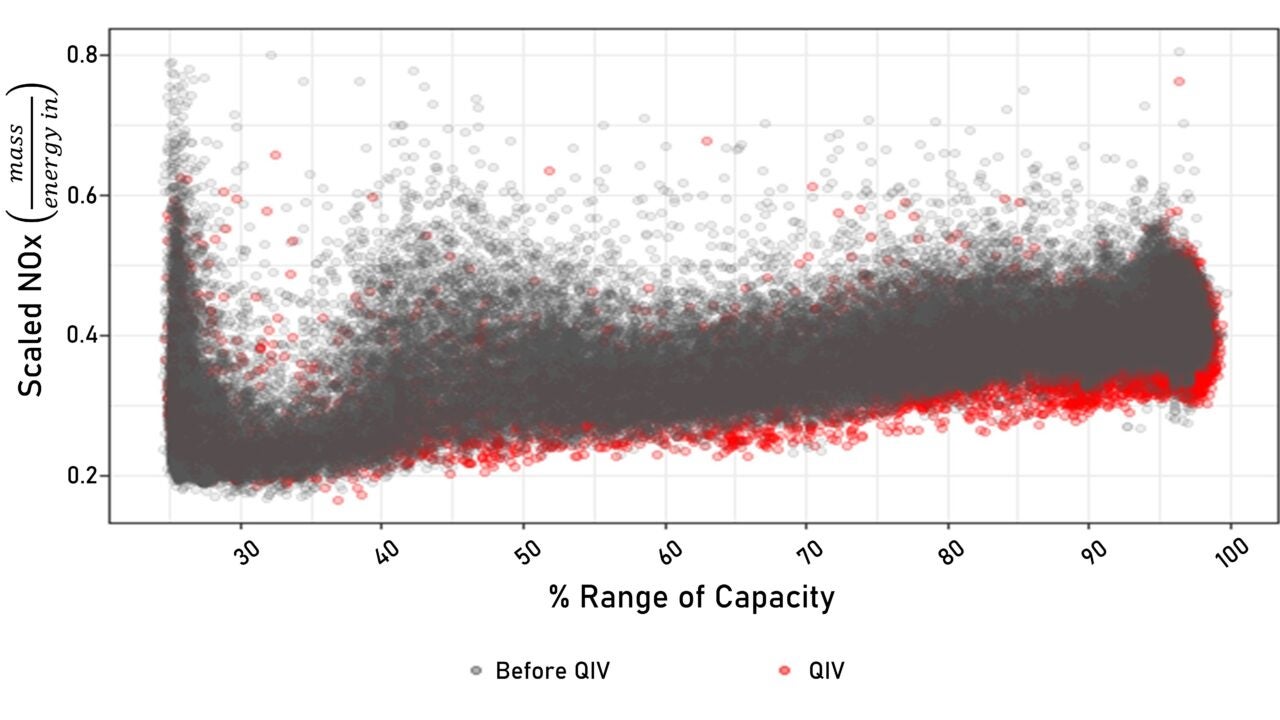

This client has several coal-fired power plants and was initially focused on reducing NOx emission rates. Taber’s team was integrated in late 2017 to meet these objectives, and immediately deployed a combustion optimization system to reduce emission rates across the load range. The system’s performance was evaluated quarterly, and it was clear that improvements were being achieved quarter-to-quarter. New “better-than-ever” performance was also observed as the system’s self-learning capabilities were able to take advantage of increased data availability and “learning through experience”.

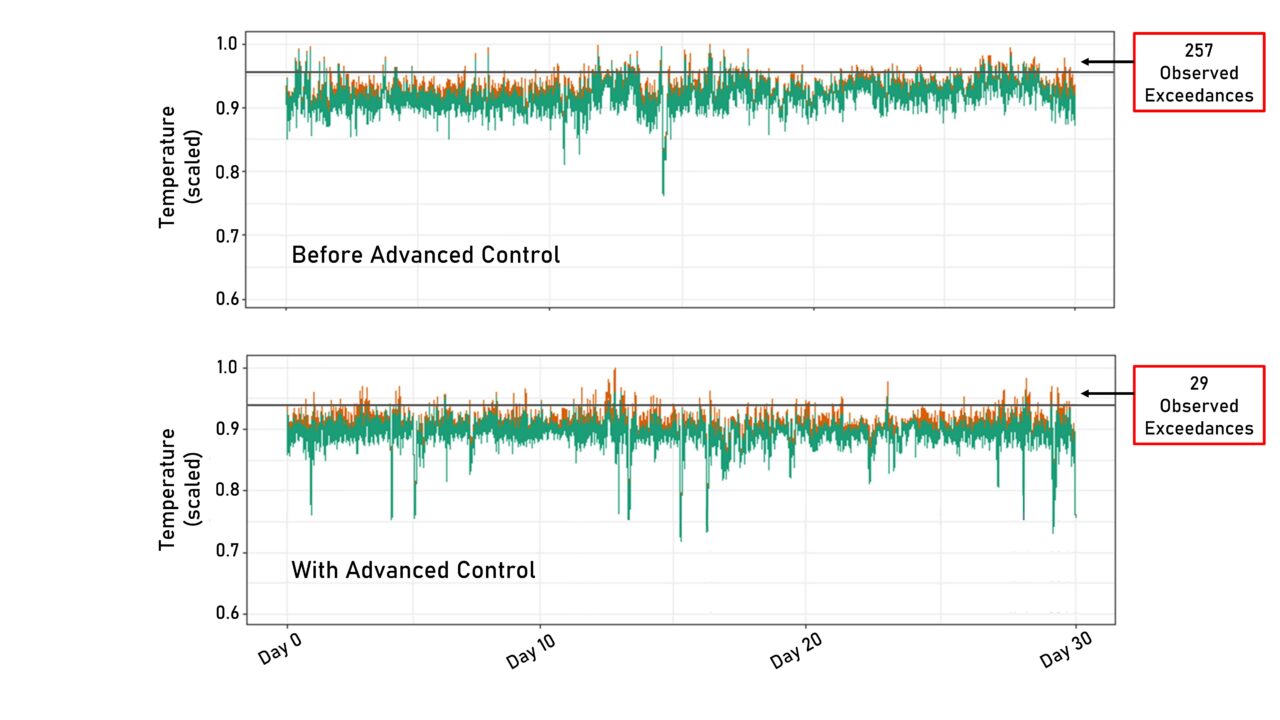

While working at NOx minimization, concerns with high tube metal temperatures became a priority. The site had tried multiple approaches to address this problem in prior efforts, but this time with Taber’s assistance and resources, a solution was quickly formulated in less than one week. The result was more than an 88% decrease in the number of high temperature events month-to-month after solution deployment.

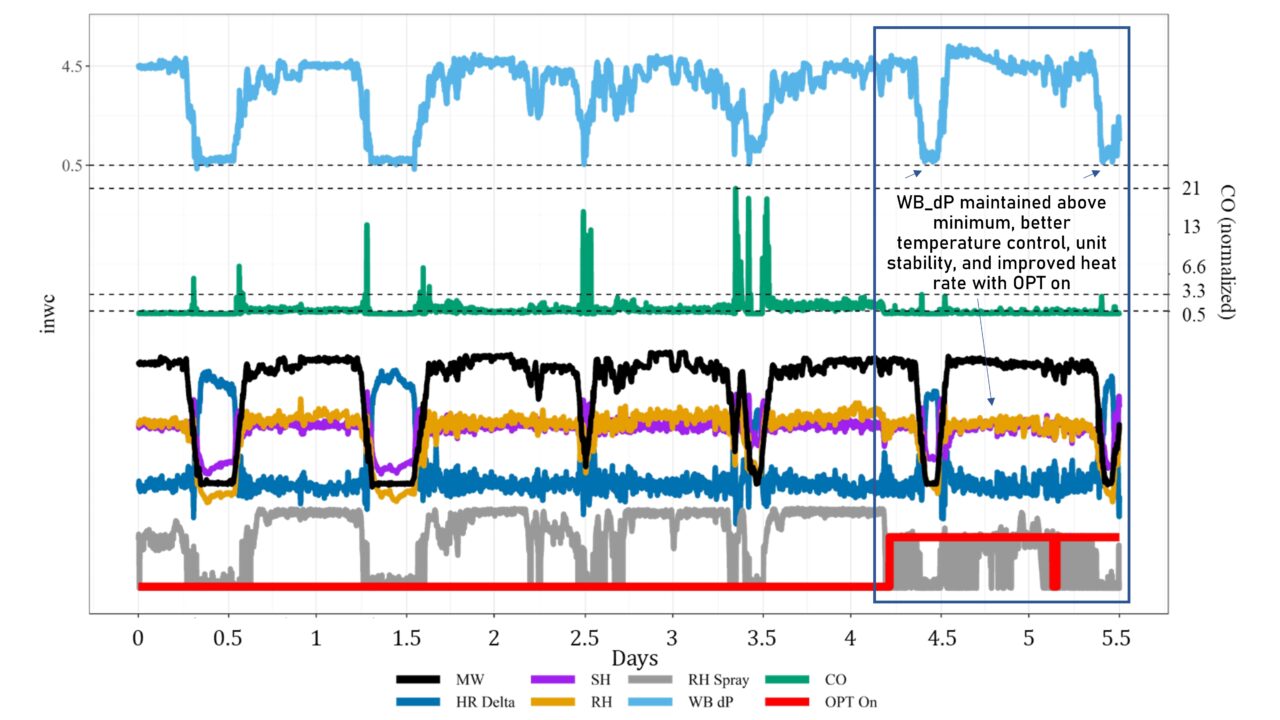

This level of reduction was obtained even while the units were operating more variably (more full-range load ramping, ultra-low loads being the cause of the increased occurrence of lower temperatures in the “With Advanced Control” period), after a short time, the units began to be dispatched at much lower loads to accommodate alternate energy sources. Maintaining unit stability and operability at these low loads was a challenge. The advanced automation and optimization systems were once again expanded to incorporate these changing objectives based on real-time load demand. Low load operation became a focus of the site, and the system was adapted to automatically prioritize unit stability and windbox pressure at low loads while maintaining existing performance objectives.

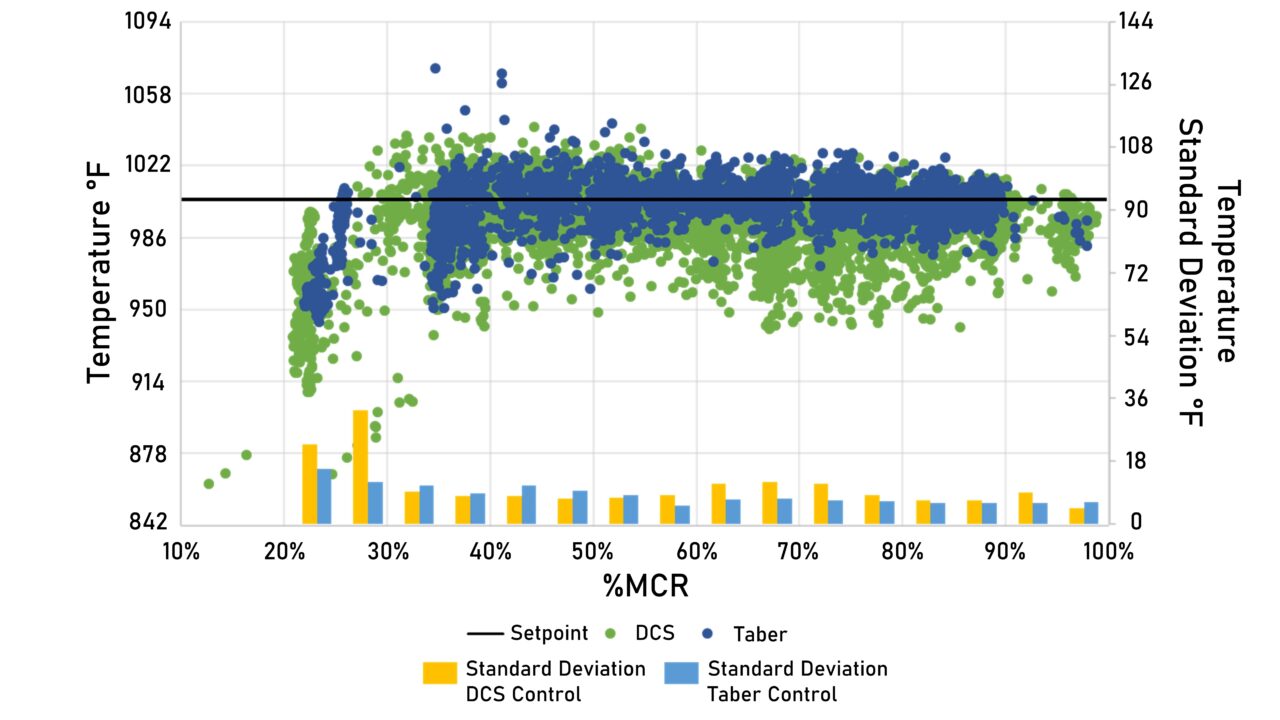

Recently flexibility, steam temperature control, and improved heat rate have again become the highest priority for the sites (while maintaining the improvements realized through prior system expansions). The existing system architecture has been adapted once more to incorporate these higher priority objectives, while balancing the previous gains and expansions within the system and overall operating philosophy. Steam temperature control has been improved 35% (improved setpoint realization) and control stability improved 27% on average across the load range.

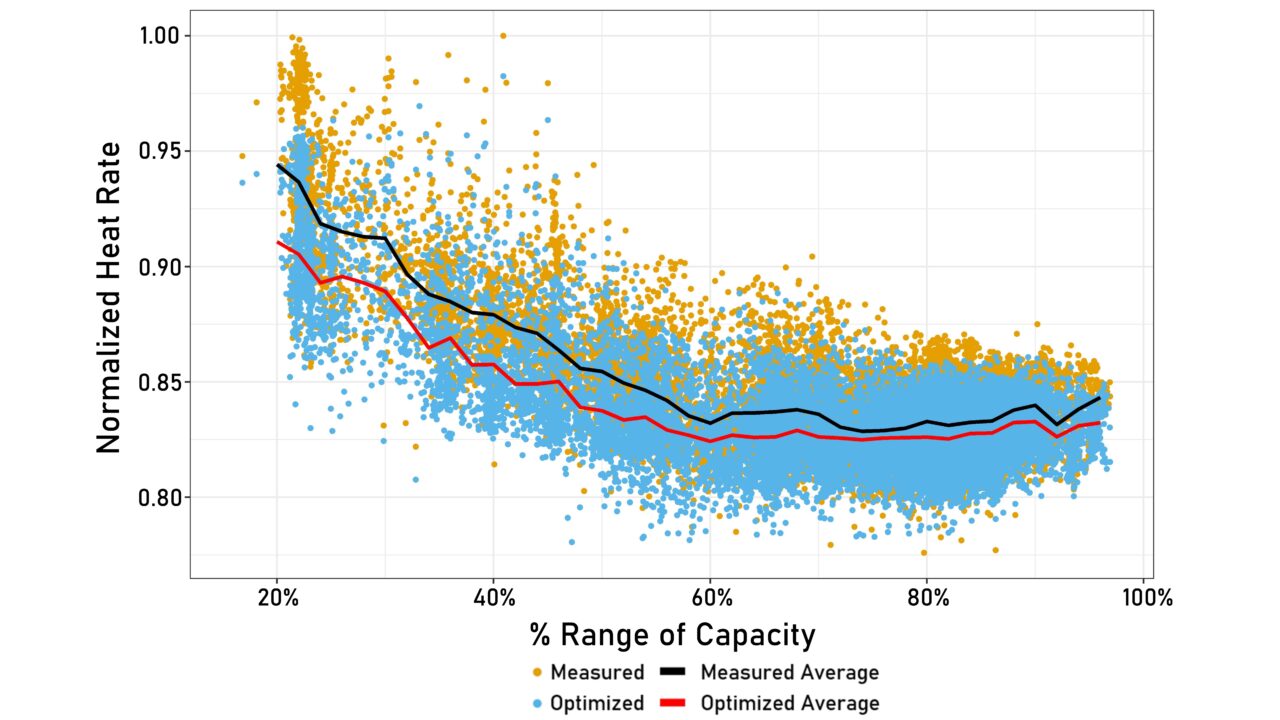

While achieving improved steam temperature control, unit heat rate benefits (represented by decreased fuel consumption at similar generation levels) have also been realized through introduction of more advanced artificial intelligence techniques (recurrent algorithms, regularization, etc.). An average heat rate improvement of 1.8% has been observed. The site has had this to say:

[We] started load cycling and low load operation back in the 2016-17-time frame. Our current load range capability is from 15% minimum MDC to 100% maximum MDC. Flexibility is our current reality and maintaining stability during load ramps takes continuous monitoring and adjustments. The inherent problems associated with load ramping and cycling (pressure swings, temperature swings, and low total air flow at lower loads) have been minimized to certain extent, by the optimizer.

In our system load ramps are almost never continuous. There may be 2-3 interruptions or pauses in the total ramp. For example, an afternoon peak load ramp may be from 15% MDC to 80% MDC with a 15-minute pause at 40% and the same at 60%. At each of these pauses is where we have seen the worst pressure and temp swings. The optimizer can anticipate these excursions and utilize the sprays and/or burner tilts to minimize the effects of the event.

I think one of the best indicators of this application is operator acceptance. Anyone who has worked at a power plant and has anything to do with operations knows “without operator by-in” the program will fail. Here our operators have seen positive results and are willing to work to make it better, which makes their life better.

– Asst. Operations Manager, Coal-Fired Power Plant, United States

Building upon these experiences and successes, other areas of the organization have recognized the flexibility and adaptability of the systems being developed for operations, and together as partners Taber has developed a digitalization framework for personnel logging, equipment rounds and checks, and general management. This recording process used to be a hodge-podge of paper forms, spreadsheets, and several other systems with varying degrees of success. Since Taber incorporated this site aspect within the system, a “one-stop shop” for everything from operations logging to personnel management has made the site’s practices much smoother and more streamlined, increasing efficiency and opportunities for further performance gains.

Taber is YOUR Partner for Effective and Continual Improvement

As circumstances and priorities evolve, it’s important to have systems that can evolve right along with these, and partners you can rely on that are oriented toward your goals and objectives. Taber is committed to being that trusted resource, aiding each and every client on their journey toward process-wide improvement and efficiency through effective innovation and data-driven transformation. From taking engineers & operations lives easier by reducing manpower and effort to achieve the same or greater levels of production and effectiveness to automated and closed-loop optimization of control systems, Taber has the experience and the capability to benefit your bottom-line. Talk with Taber today to take the first step on your process improvement journey.