Among those talking with POWER about reliability enhancements for the power grid was James Nyenhuis, plant performance consultant for Emerson. Nyenhuis provided POWER with insight about the work being done to support a reliable supply of electricity, from the power plant to the edge of the grid.

POWER: What are some enhancements that can be made to an electricity transmission and distribution system and/or a power plant (thermal or renewable) to improve its reliability?

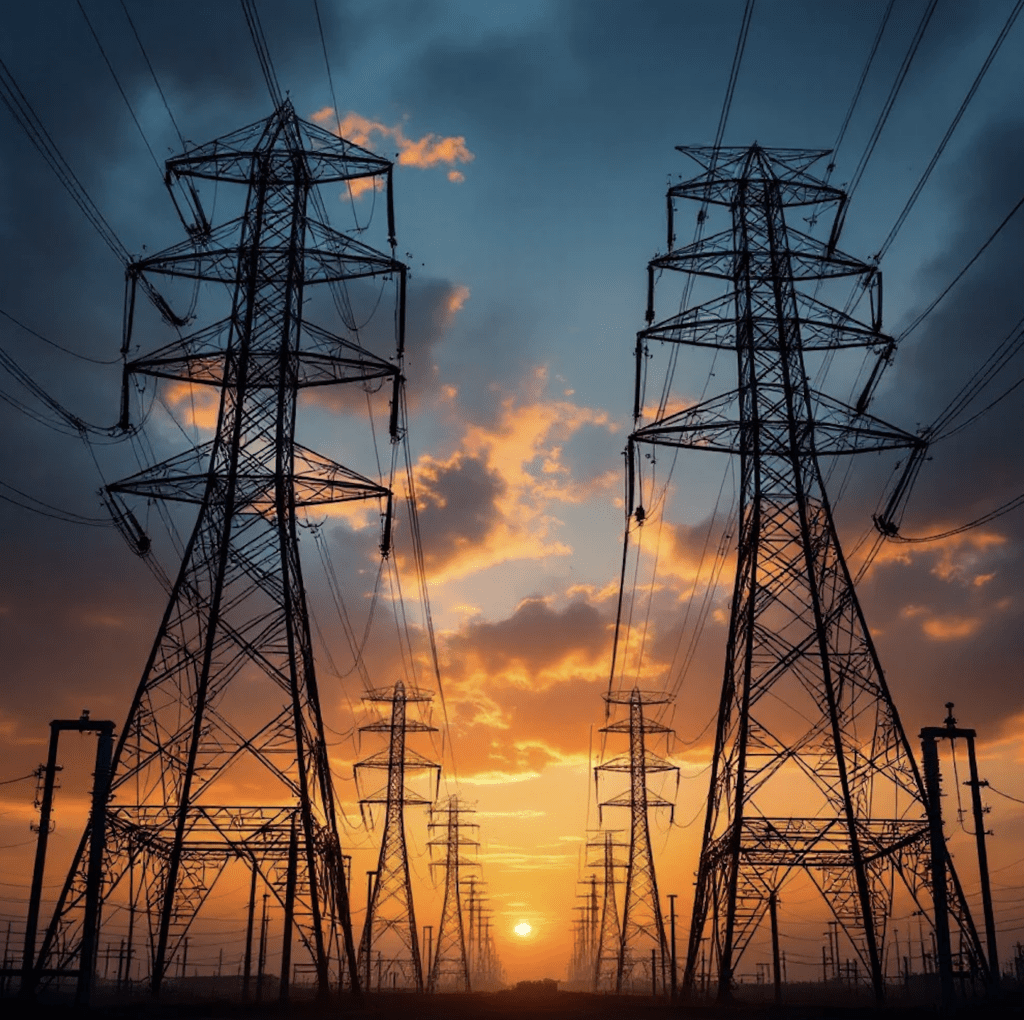

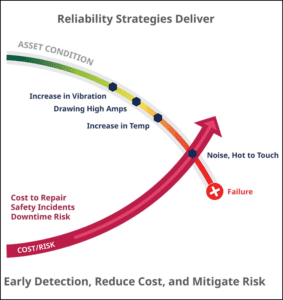

Nyenhuis: Reliability has always been a key focus for the power generation industry, but what we see changing significantly in today’s environment is a continued evolution of technologies, which provide efficient means to process more information closer to its source and provide earlier detection of evolving reliability risks [Figure 1]. One of the first enhancements that comes to mind, which can improve reliability of the power generating facility, is to ensure that operations teams are supported by a well-designed alarm and alert management process.

Figure 1. Comprehensive asset performance management focuses on

critical assets that require immediate attention to improve performance through

increased production and decreased maintenance costs. Courtesy: Emerson

Many plants we engage with today are still burdened by underperforming alarm management systems that overload operations staffs and induce reliability risk by making it harder for operations teams to identify evolving issues. Significant impacts to reliability can be made with the right investment in optimizing the performance of the alarm system and providing clear identification to off-design process conditions to plant personnel.

Additionally, when off-design issues have occurred, we have seen advanced control strategies provide better coordinated responses due to their predictive control capabilities. These predictive capabilities allow the control actions to better steer through transient dynamic conditions and maintain stability, providing the plant an increased chance to stay online after these types of events.

Lastly, we are seeing technology enhancements at the “edge” that allow a better convergence of information from asset health, analytics, control, and performance to provide earlier detection of evolving issues from critical plant assets before they demand a real-time response from the automation system.

POWER: What are some of the maintenance programs that can be implemented to make a power plant and/or a power grid more reliable? How can this maintenance be automated?

Nyenhuis: Having a proactive maintenance strategy is the secret against declining operational performance and managing risks to reliability. More and more, power customers are expecting intelligence to be built by default into the solutions they acquire. Ideally, we don’t want a plant operator to have to notice that an alarm is intermittently coming in and going out to start a chain of events that leads to the identification of an under-performing cooling loop control, as an example. We want that control loop to be monitoring itself and raising its hand, telling somebody when it needs attention. That is how we need to be leveraging technology.

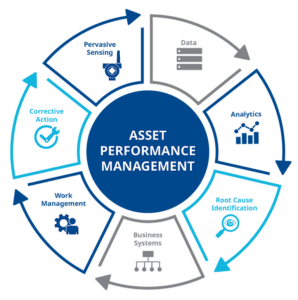

This same concept can be applied to the management of instrumentation, critical rotating equipment, control valves, etc. New technologies are allowing us to achieve these goals. Advancements in software [Figure 2] allow us to automatically communicate with assets and provide automated reporting and confirmation of expected operation. If the need arises, there’s the ability to proactively notify the appropriate personnel via text or email of a potential problem that needs attention.

Figure 2. A proactive reliability management strategy is the secret

against declining operational performance while improving

process availability and lowering operating costs. Courtesy: Emerson

POWER: How important is redundancy as part of power plant/power grid operations?

Nyenhuis: The criticality of redundancy varies within different applications across the power generation playing field. Obviously, we will always ensure that safety is the top priority and deploy the right level of redundancy to maintain safe plant operations within industry best practices. Beyond safety considerations, there can be economic tradeoffs between the investment costs in additional levels of redundancy and the lost economic opportunity if the plant isn’t available to produce power.

Generally, we are seeing a trend towards leveraging software applications to provide a more sophisticated risk analysis around the potential impacts of not having redundancy as it pertains to achieving the financial or operational goals of a process. As an industry we have tended to design processes and equipment around static, fixed type assumptions, but we see this changing as the power generation world gets more sophisticated and dynamic. Technology allows us to more accurately model potential risks with historical data and design assumptions. These tools provide quantitative ways to balance the goals of process availability against the costs associated with various levels of redundancy.

POWER: How can operations be standardized to improve reliability?

Nyenhuis: One of the things that we are seeing is our customers leveraging additional levels of automation implementation within their existing technology to encapsulate operational expertise directly within the base level automation infrastructure before the existing expertise leaves the industry. This process forces customers to pull the right cross-functional team together, those who know the specific characteristics of the plant they operate and maintain. This leads to embedding the best practice operational procedures in sequence automation that can be leveraged over and over, driving consistency and repeatability. Tracking the appropriate metrics over time, such as startup times or fuel consumption, as well as operator interactions with the distributed control system, shows that operational consistency is enhanced and, over a longer time horizon, reductions in overall lost megawatt-hours have been achieved, directly improving reliability goals.

POWER: What are some of the specific components/equipment that can be used to enhance reliability?

Nyenhuis: We have found the best way to enhance reliability is to look back and wade through available data to understand, to the degree possible, what items show up as key negative contributors to a plant’s overall reliability metrics.

Do particular trends show up? What types of events have led to the most lost production over the past number of years? Depending on the answers to these types of questions, different approaches may be called for.

Can a particular system or set of systems at a plant be identified as a key contributor? If so, aligning specific available technologies to manage the risk these systems pose may be warranted.

If human performance factors are a large contributor to lost generation, review of automation system performance and alarm management implementation may make sense. There is an abundance of useful technologies out in the market today: the challenge is aligning these technologies with stated risk mitigation objectives in as an efficient and cost-effective way as possible.

POWER: How can model predictive control be used to enhance reliability?

Nyenhuis: We have seen a significant increase in our customers deploying model predictive control in appropriate areas of the process such as steam temperature control, drum level control, load, and emissions control, as well as other critical process areas. The impact we are seeing to enhance reliability is model predictive control’s ability to better manage critical off design situations.

When the control can be predictive in nature, we have seen it have a better ability to coordinate multiple control responses, ideally returning a process to a stable state after a critical upset, even if it is at a degraded output. For example, we have seen model predictive drum level controls better manage upsets to dynamic steam transition issues related to a combined cycle bypass system. When we have the predictive ability to steer the process through the upset, we increase the ability to avoid unit trips, which increases overall process reliability.

POWER: How can a program be implemented to enable proactive replacement and/restoration of older equipment (both software and hardware) in power plant and power grid systems?

Nyenhuis: This effort connects to a question posed earlier and centers around what is known about the effective lifecycle stage of critical assets and systems coupled with an understanding of current symptoms that can be observed. We liken this to trying to understand whether an aging asset is like a fit 82-year-old with no indication of cholesterol issues, normal blood pressure, and a clean medical history, or is it an overweight 74-year-old with a history of medical issues such as hypertension, diabetes, and high cholesterol.

We have the ability, with technology today, to accurately track the “age” of critical assets and perform both periodic and continuous tests to monitor health symptoms and stress levels. Implementing these technologies and aggregating them into easy-to-understand outputs helps us understand where the “doctor” needs to focus.

As previously discussed, reviewing historical data and what may be currently available to understand existing “symptoms” helps set the stage for where to initially focus efforts. We want to ensure there is a clear picture of asset criticality across the plant. Understanding a picture of historical impacts to unit reliability and ensuring this analysis lines up with asset criticality lens sets the stage for how to move forward.

Ideally, we want to deploy a proactive reliability management strategy that centers around actively monitoring the risk of aging assets while improving process availability and lowering operating costs. We especially want to identify any critical assets that require immediate attention. For ongoing monitoring, we want to leverage existing failure mode and effects analysis (FMEA), reliability strategies, work procedure development, and computerized maintenance management software (CMMS) integration to help focus initially on proper risk management of any identified high-criticality assets that may show signs of excessive age or poor health. These efforts allow us to target an asset management program and associated technologies that directly impact known reliability risks and lay a foundation that supports future expansion.

➡ LEARN MORE from EMERSON about Power Plant Optimization Software

—Darrell Proctor is a senior editor for POWER.