For investor-owned utilities looking toward complying with the requirements of a clean energy future where flexibility, reliability, efficiency, and low emissions are paramount, reciprocating engines (RICE) could provide a viable option in addressing power generation needs.

For investor-owned utilities looking toward complying with the requirements of a clean energy future where flexibility, reliability, efficiency, and low emissions are paramount, reciprocating engines (RICE) could provide a viable option in addressing power generation needs.

Investor-owned utilities (IOUs) partner with technology companies like Wärtsilä, to serve their power generation needs. Wärtsilä’s RICE technology enables power providers to deliver reliable, affordable, secure and clean energy. RICE are a useful generation technology for balancing renewable energy resources and allow for higher penetrations for IOUs. These engines have several characteristics that make them ideal for balancing. These include:

Fast start-up: What sets RICE apart from other power generation technologies, is that RICE can be started and brought to full power quickly, making them a solution for responding to sudden dips in renewable energy production.

Flexible operation: RICE can also operate at varying power levels, making them suitable to adjust to the match the changing output of renewable sources.

Part-load efficiency: Reciprocating engines can even operate at low power levels, which is important when only small amounts of balancing power are needed.

Grid Stability: By adjusting quickly to their output, RICE can prevent power fluctuations on the grid caused by intermittent renewable sources.

Future Proof Power Solutions: Wärtsilä RICE technology can deliver future proof power solutions that contribute towards decarbonized operations through hydrogen-blended fuels.

It’s evident, IOUs share a common thread: the need to produce more electricity with a greater share of renewable inputs at the lowest cost to ratepayers possible. Wärtsilä’s RICE technology is designed with this in mind and has the capacity to improve effectiveness of power generation even in the most extreme conditions.

Flexible in its application, Wärtsilä’s RICE engines provide benefits to a wide array of utility profiles, as demonstrated by the variety of customers they serve. Wärtsilä works with power suppliers that only use RICE, (i.e. no gas turbines) to those using RICE to balance their renewables, and to customers combining RICE with their gas turbines. The value and adaptability of Wärtsilä’s technology is evident in the successes demonstrated by their customers. The following example illustrates Wärtsilä’s commitment to clean energy solutions designed with IOUs in mind.

Looking to the future in Wisconsin

WEC Energy Group started the search for the right generating units to serve the needs of their utility company in Michigan about ten years ago. “Quick start, very flexible, modular gas plants really suited our needs,” said Dan Krueger, Executive Vice President of Infrastructure and Generation Planning at WEC Energy Group. “Wärtsilä has the track record globally. They have a good US presence. We’re very satisfied with the RICE technology. They were delivered on-time and on-budget. The units have met our needs, and we now have seventeen Wärtsilä units in our fleet, with more planned.”

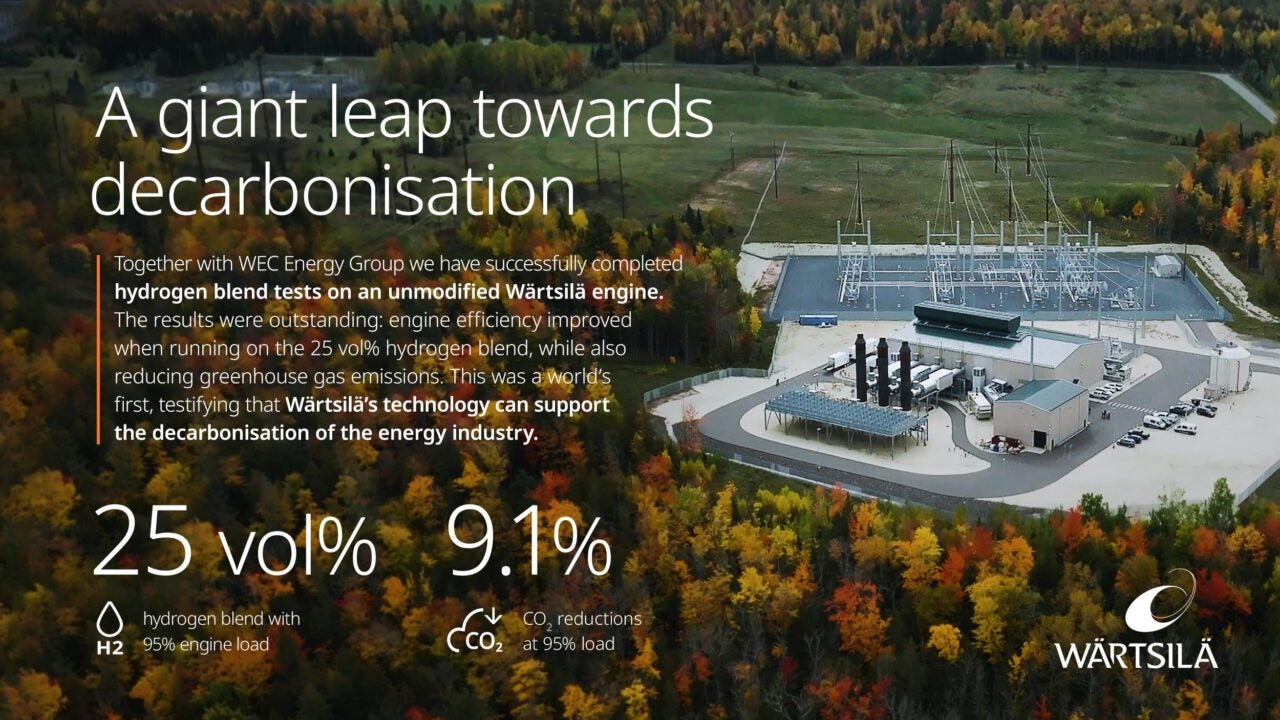

It was this type of Wärtsilä engines that piloted the first hydrogen fuel blend test of its kind. Together Wärtsilä, EPRI, Burns and McDonnell and WEC Energy Group successfully tested the capabilities of a Wärtsilä engine running on 25 vol% hydrogen-blended fuel. This pilot makes Wärtsilä’s RICE the largest commercially operated flexible balancing engine ever to run on a hydrogen fuel blend.

Over the course of three days of continuous testing, the capability of the engine to co-fire hydrogen blends was successfully demonstrated, showing clear improvements in engine efficiency and reduced greenhouse gas emissions, while remaining compliant with NOx emissions. A 95% engine load was achieved with the 25 vol% H2 blend, verifying the fuel flexibility of Wärtsilä engines without compromising efficiency. Further testing showed that with a 17 vol% H2 blend, a 100% engine load was attainable.

“The pilot was a success. It showed us that these engines can run on a 25% hydrogen blend without any significant impact to the engine efficiency, while also reducing emissions,” Krueger continued.

Additionally, the engine tested with the H2 blend was not mechanically modified. Meaning, the engines did not undergo any part changes. This demonstrates that Wartsila’s RICE technology can adapt to hydrogen blended fuel safely, efficiently and reduce CO2 emissions.

WEC Energy group has some of the most aggressive CO2 reduction goals of any electric company in the US. WEC Energy Group is aiming for a 60 percent reduction from a 2005 baseline by the end of 2025 and an 80 percent reduction by the end of 2030. Their CO2 reduction strategy can be summed up as affordable, reliable and clean. To reach these goals, they must balance a set of significant challenges, including load and demand growth, new EPA clean air rules, evolving grid operator rules and renewables penetration on the grid. “These Wärtsilä machines, with their flexibility, modularity and quick ramping are an important tool for us as we work towards meeting our environmental goals and continue to serve our customers with reliable and affordable energy,” said Krueger.

The success of the test continues to fuel Wärtsilä’s research and development efforts around the launch of a 100% capable hydrogen engine. The company is exploring the planning phase of the project searching for a viable partner to pilot a 100% hydrogen ready engine and potentially provide a 100% hydrogen solution to the broader market.

WEC Energy Group, which serves 4.7 million customers in Wisconsin, Illinois, Michigan and Minnesota, are repeat customers, choosing Wärtsilä to help achieve their plan to retire older, less efficient fossil-fueled generation and to exit coal by 2032.