Power generators continue to expand their use of digital technologies. Data analytics, artificial intelligence, and machine learning are all part of a rapid transformation in how utilities are improving the efficiency of their operations, and increasing the reliability and resiliency of electricity production.

Power generation is all about connections. Power plants need to connect to the grid. Utilities need to connect with their customers. Connectivity is a buzzword as generators deal with a fast-changing operating environment, with utilities facing competitive threats and government mandates that call for new business models.

Operational challenges are mounting. Customers are demanding more reliability, resiliency, and sustainability from their power providers. Cybersecurity is a growing concern. Technological advances are being deployed to address these issues, with high-level internet technology (IT) and analytics programs leveraging data from connected devices throughout power plants and across field operations.

If connectivity is a buzzword, so are reliability and resiliency. The Eaton Blackout Tracker, which tracks power outages worldwide, reported that the U.S. experienced 3,526 utility power outages in 2017—a 62% increase in outages from 10 years earlier. The U.S. Department of Energy (DOE) said power outages cost the nation’s economy $150 billion annually.

Utilities are looking to technology to minimize those outages, reduce downtime for their power plants, make their operations more efficient—and above all, reduce costs. Investment in digital technology is rising, with networking for numerous utility applications accelerating and solutions for solving connectivity problems diversifying.

Jean-Pascal Tricoire, CEO and chairman of Schneider Electric, speaking at the company’s Innovation Summit in Atlanta, Georgia, last November, said, “Connectivity is the foundation of life in the 21st century. Think about the Internet of Things [IoT]—we are connecting 10 times more things than we are people to the internet.”

Said Tricoire: “When we started in digitization, the biggest thing we looked at was energy efficiency. [Now] we are looking at productivity, reliability, safety, sustainability. Now we can ‘connect the connected,’ through aggregation of data. We go from reactive maintenance to proactive, predictive maintenance.”

Mohamed Shishani, the EcoStruxture Power deployment leader at Schneider Electric, in a recent interview with POWER said, “How is it ‘OK’ to have a main breaker feeding your equipment not connected and supplying data? From that standpoint, we’re trying to raise the awareness of what [value] is added to that project. You cannot improve what you don’t measure. If you don’t know what’s going on in your facility, how can you improve your facility? We’re really trying to advocate for reducing your risk appetite. It’s not added cost, it’s about what can the data do for you?”

The Rise of Digitization

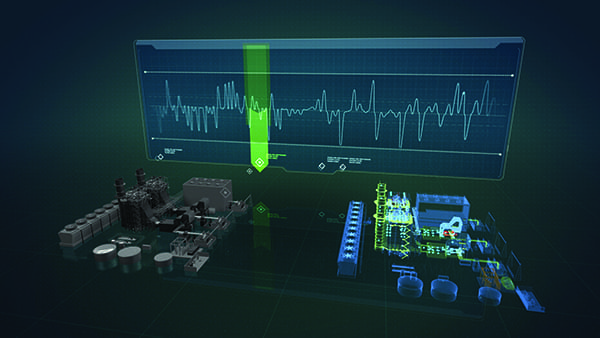

Paul Donnellan, a partner at Chicago-based Clareo, which uses software and other tools to help utilities and a variety of businesses develop operating strategies, told POWER in a recent interview that his group has met with many power industry leaders over the past year to “produce some thought leadership covering the new energy future, including power generation. The input included more than 20 interviews with industry leaders across the value chain, different players from electric utilities, power generators, and suppliers. We talked about digitization, how to leverage digital technologies to improve power generation assets, make them more efficient, more reliable. That includes maintenance, and deploying digital twins (Figure 1).”

|

|

1. Digital twins, created as part of asset performance management systems, enable power plant operators to be more proactive with maintenance, spotting potential problems before they occur. This reduces downtime and service costs. Courtesy: GE Power |

The increasing role of digitization in power generation is a focus of POWER magazine’s Connected Plant Conference, which will be held in Charlotte, N.C., Feb. 19–21. As Donnellan noted, the current competitive environment for power generators is accelerating the adoption of digitization in power plants.

“There is tremendous cost pressure for nuclear plants,” Donnellan said. “The combination of all those pricing pressures is putting a lot of emphasis on maximizing assets and reducing costs. Identifying problems before they happen. When they do have to go to maintenance, they can do it more efficiently. That’s driving down costs and increasing reliability for customers.”

He continued: “It’s important to get a virtual representation of your assets—getting real-time data, getting insights much faster when system repairs are needed, and shortening the time needed to repair. For those [utilities] operating renewables, it’s about the ability to predict wind patterns to optimize the turbines and operations. Another area is drones, using them for inspections in the field, and how that helps reduce costs. It’s about using data to optimize [power] plants.”

Digital technology is being used for design and engineering of power plants, and in their production and operations (Figure 2), with various components networked to communicate with each other and exchange real-time data. It includes machine learning—for example, a wind turbine can increase its electricity output by adjusting its operation to weather conditions.

|

|

2. Today’s power plants are increasingly a model of connectivity, where data is fed from various operating components, all networked to communicate with each other. Operators can quickly see equipment anomalies, such as a turbine running too hot. Courtesy: Siemens |

The Weather Company, which provides technology and services that leverage weather data for businesses, is among those offering software to aid utility operations, from helping with energy trading, to load forecasts, and outage prediction. The company’s Outage Prediction Model uses a machine-learning, predictive model that combines historical weather data with local weather forecasts—and historical outage data—for a service area. It enables utilities to determine what areas could be hit by severe weather, and pre-stage restoration crews and equipment accordingly.

Then there’s cybersecurity. Paul Hingley, the Data Services business manager at Siemens UK, recently told Britain’s East Midlands Business Link that companies making the digital transformation must identify cybersecurity priorities and work to protect data.

Said Hingley: “It is based on the use of cyber-physical systems where the growth of connected devices through the Internet of Things will see digital transformation increase industrial plant performance. In addition, applications and digital services will also help build new digital business models that will differentiate organizations in the market.”

Hingley called it the fourth industrial revolution, with data at the center. “Estimates predict that the total volume of data generated globally by 2020 will exceed 45 zettabytes—up from 7.4 zettabytes in 2015. This will, in part, be as a result of the growth in machine-to-machine connectivity through sensors, meters, devices and industrial machines. Seamless and intelligent digital technology platforms, including virtual and augmented reality, digital twins and simulation, cloud technology and cybersecurity protection, are set to have a profound impact on our industrial landscape over the coming decade.”

Benefits for Utilities and Customers

Ravi Parakkat, director of global markets for Sapient, a consulting firm specializing in business and technology, gave POWER an example of digital technology designed to benefit both a utility and its customers.

“Our organization [in 2018] partnered with Oshawa Power [of Ontario, Canada] to launch a new pilot program called Peak Performance Pricing. The program couples smart meter energy consumption data with other proprietary data sources to provide insight into household electricity use,” Parakkat said. “The program uses advanced technology to develop a range of digital tools and applications, such as a web portal, email, text messages, specially-trained customer service representatives and a mobile app, to help educate consumers and spur action across various channels.

“For example, the program combines daily weather forecasts with customer-specific behavioral data to formulate customized text and email messages featuring cost-effective heating and cooling recommendations. By using multiple sources of data, Oshawa Power is able to tailor not just the message—suggesting when to raise thermostats or avoid using air conditioning during peak hours, for example—but the time of day the message is sent and the channel used. In this way, the Peak Performance Pricing program provides customers with the information they need, when they need it, in the way the prefer—making the communication both relevant and actionable.”

Parakkat said the program could reach 13 million people. “It is slated to reduce energy costs by 4% to 6% per household, while also improving the sustainability, reliability and efficiency of Oshawa’s power system,” Parakkat said.

Advanced Analytics Software

Brendan Duval, CEO of Glenfarne, whose subsidiary Enfragen owns and operates energy and other infrastructure assets in areas including Latin America, told POWER that his group focuses on “two silos: grid stability with Prime Energia SpA and our renewables initiative with Fontus Hydro.”

Duval said that with fleet management, “We believe our edge is in efficiently owning and operating multiple small assets,” noting his group is building a network center in Santiago, Chile, where Prime Energia is headquartered. “We want to use [digital technology] to optimize the individuals at our power plants and maximize the flow of information to the central headquarters,” he said.

Prime Energia is an owner-operator of standby power plants, with facilities in Chile, Peru, Colombia, and Panama, with an eye toward North America. “We’ve designed our [Santiago] control room with a digital footprint,” Duval said. “It’s all about producing power on demand. They’re online, they’re able to dispatch [as needed]. We can control our gensets [generator sets] and do security monitoring of the facilities, some of which are quite remote.”

Duval said they also can be proactive with maintenance. “We can get data from our assets, look at any equipment failures, call up a ‘histogram’ to see how assets are performing. We are doing that to reduce headcount [at individual facilities], to increase security.” Duval said a video wall in Glenfarne’s New York City office also enables monitoring of what’s happening with the power markets where the company’s assets operate.

“Latin America markets don’t have very transparent pricing for the power market,” Duval said. “We are able to basically mirror what’s happening there with power production, scraping public data, to create our own real-time information on the markets.”

Asset Performance Management

With increased digitization, asset performance management (APM) has become a big business. Uptake, a Chicago-based artificial intelligence (AI) and IoT software company, recently released the latest version of Uptake APM, an interoperable “software-as-a-service” product that builds on Uptake’s popular Asset Platform, which is used in several major industries and by many power generators.

Sonny Garg, Energy Solutions lead at Uptake, told POWER, “We are at the very beginning of making the energy sector smarter through AI, machine learning, and data science. Power plant operations managers should be thinking about digital to get the most out of existing assets by making them more reliable and productive through data-driven asset performance management. Optimizing maintenance strategies and identifying areas to increase operational efficiency based on predictive insights frees up capital for future digital investment. Businesses must optimize assets today and then get to real digital transformation that allows them to tap data to seize new opportunities.”

Garg said Uptake last year analyzed 20 years of Federal Energy Regulatory Commission data on 2,500 power plants across the U.S. (about 40% of all U.S. generation). “What we found is that there has been a significant, sustained rise of non-fuel power generation operations and maintenance costs. The cost to operate and maintain U.S. power plants and equipment has soared 74% over the past two decades,” he said

Garg cited the Palo Verde Nuclear Generating Station in Arizona as an example of using APM to save time and money. He said Palo Verde, using Uptake’s APM application, reduced its annual working hours spent on preventive and corrective maintenance by 37%; realized $10 million in annual cost savings, representing a 20% cost reduction; and improved its overall capacity factor as it set a record for power production. The plant has been among the world’s top nuclear producers, and the top power producer in the U.S.

The IoT Operating System

Siemens is another company at the forefront of digitization to optimize operations. The company’s open cloud platform, MindSphere, “is a centerpiece of a powerful IoT operating system with data analytics and connectivity capabilities, tools for developers, applications and services,” according to the company, which says the platform “helps to evaluate and utilize your data and to gain breakthrough insights,” and “drive the performance and optimization of your assets for maximized uptime.”

Siemens, which has Digital Experience Centers in various global locations to showcase its digital enterprise systems, notes that digital technologies can “generate performance improvements across the entire value chain, from design to production and operations to maintenance.” In practice, it means sensors in gas turbines “collect data, monitor conditions, automate functions and optimize processes by utilizing the possibilities of the digital twin as well as consistent data models.” It includes “advanced algorithms, high-powered computing, better connectivity and cloud storage [that] all facilitate the emergence of smart systems.”

Those smart systems are reaching all aspects of power generation. Said Clareo’s Donnellan: “We’re also seeing some use of augmented virtual reality for training, where you can represent an asset and train an employee on how to do something for inspection or operation, train them in a way that more closely represents the asset and increase worker safety.”

Donnellan noted that virtual reality “also increases reliability, increases uptime. Safety, training, it’s really interesting to see how companies are going about this. We’re finding that companies are partnering with other companies that are proving the technology. You’re seeing deepening partnerships with these technology companies and generation companies, and groups partnering to test these technologies.”

“We are doing a lot with IoT development and IoT networks,” said Hendrik Van Asbroeck, managing director of Engie Fab at ENGIE, a French multinational utility company, in an interview with POWER. “We’re working with B2B [business to business] customers, but we’ve been saying among ourselves, ‘Why couldn’t we use this technology to make our power plants more efficient, use this to improve reliability?’ Any change in energy is driven by technology.”

ENGIE’s foray into advanced technologies was showcased in January at the Consumer Electronics Show (CES) in Las Vegas, a show that for years focused on the latest high-tech gadgets from the world of computers, televisions, and audio and video. The show in recent years has been dominated by devices for the connected home, along with automotive technology. Van Asbroeck said the energy industry is a natural fit.

“Think about how we’re moving toward decentralized energy. It’s a change in energy, in power generation, driven by technology,” he said. “There are DERMS (distributed energy resource management system), which we have been developing, to form that link between decentralized [generation] and the company, making it possible and cost-efficient.”

DERMS is the term for software designed to integrate the needs of utility grid operators with the capabilities of flexible demand-side energy resources at the edges of the grid. These systems vary in their organization and size, but have come from both large and small energy companies, including GE, Siemens, and Schneider Electric, as well as smaller firms such as Advanced Microgrid Solutions and Opus One Solutions.

Most DERMS are organized in two ways: as extensions of a utility or grid operator to customers, or as aggregations of customer loads into grid energy markets. Van Asbroeck noted the systems’ importance to demand response, among other issues, as well as their role in helping bring power to the developing world.

“Access to energy is a very important topic for the world,” Van Asbroeck said. “Part of our presence at CES was to show what [ENGIE] is doing in developing countries, to show our IoT development and our IoT networks.”

As Matt Ross, executive vice president and chief marketing officer of California-based Bloom Energy, said at the company’s recent media day attended by POWER: “We live in a digital economy. The quality and reliability of power is paramount. You can’t run a digital economy without dependable electricity. And technology brings new possibilities.” ■

—Darrell Proctor is a POWER associate editor (@DarrellProctor1, @POWERmagazine).