In This Issue

-

Nuclear

Arc flash protection should be job No. 1

Arc flash is arguably the most deadly and least understood hazard faced daily by plant personnel. Research indicates that even the best safety plan, training regimen, and protective equipment may be no match for the heat and blast effects of an arc flash. Consider this article a wakeup call to retrofit every switchgear cubicle in your plant with a properly designed remote racking system. Forewarned is forearmed.

-

Instrumentation & Controls

Innovative boiler master design improves system response

A quick and nimble boiler distributed control system can end up moving at the speed of molasses in winter after a low-NOx retrofit. In one utility fleet, several units—despite being equipped with a modern DCS—were experiencing firing system time lags and degraded dynamic loading capability. Swinging steam pressures and opacity excursions were forcing operators to constantly remove the unit from the load dispatch. Read how a new boiler master design read the riot act to those unruly steam generators.

-

O&M

To optimize performance, begin at the pulverizers

A systematic, performance-driven maintenance program for optimizing combustion can achieve great results. The challenge for an O&M staff is deciding which proven strategy and tactics for reducing NOx and improving plant reliability to adapt and implement. The structured approach presented here has proven its worth at several plants that have wrestled with problems similar to yours.

-

O&M

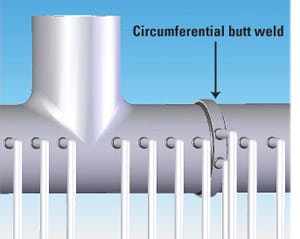

Finding and fixing cracks in high-temperature headers

The welds on superheater and reheater headers are arguably the most stressed parts of a modern steam plant. For that reason, it’s surprising that they also may be the most under-inspected. Cracks are rare, but they can be repaired if found early. One plant avoided a long forced outage to replace a reheater outlet header by using the correct condition assessments and welding techniques.

-

O&M

SO3’s impacts on plant O&M: Part II

Part I of this three-part series (POWER, October 2006) explored the negative impacts of sulfur trioxide (SO3) on the operation and maintenance of back-end plant equipment. In this issue, we list and quantify the likely and potential benefits of limiting the concentration of SO3 in flue gas to 3 ppm at the entrance to the air heater. Part III—to appear in the April 2007 issue—will describe the characteristics of an optimal SO3 removal technology and present the technical details and operating experience of one patented process that has worked successfully at a half-dozen plants for up to three years.

-

Coal

Sealing abandoned mines with treated flyash kills two birds with one stone

Environmentally benign disposal of coal combustion products/by-products (CCPs) such as flyash and bottom ash has been a problem since the first coal-fired power plant went on-line. In recent years, ways have been developed to recycle CCPs into useful commercial products like bricks and roadbase. This article describes an innovative State of Maryland program that is putting CCPs to yet another use: stabilizing abandoned mines to permanently sequester acids and harmful metals.

-

Coal

NOx, SO3 in the spotlight at NETL’s 2006 Environmental Controls Conference

As emissions caps drop, technological solutions must become increasingly effective and efficient. Researchers, equipment vendors, and plant operators are exploring alternatives to SCR and SNCR, with a view to reducing the overall costs of NOx reduction. They’ve also achieved 95% to 99% removal of SO3, with no visible plume opacity.

-

News

This month in POWER . . .

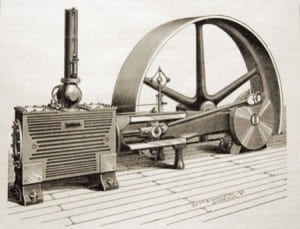

February 1885 The cover story examined the latest in reciprocating engine technology: the Greene automatic cut-off engine (Figure 1). Here is how the editors described it: “The engine has a girder frame; guides case separate and dowelled and bolted to the bed plate; four-part main boxes; Porter governor. There are two steam and two exhaust […]

-

Commentary

Will FERC’s transmission siting rule create more jurisdictional conflict?

Federal Energy Regulatory Commission (FERC) Order No. 689, issued on Nov. 16, 2006, established requirements and procedures for granting permits to build transmission facilities within “national interest electric transmission corridors” designated by the U.S. Department of Energy (DOE). After summarizing the statutory and regulatory background, this opinion piece addresses jurisdictional conflict between FERC and states, […]

-

Environmental

Birds in the hand for CO2

The January call for a national policy on greenhouse gas (GHG) emissions by a coalition that includes some of America’s largest companies and electric utilities—GE, Alcoa, Dupont, Duke, FPL, and PG&E—makes clear that carbon management is now as much of a raison d’être for CEOs as it has been for environmentalists. The momentum to reduce […]

-

Gas

Global Monitor (February 2007)

China to buy four AP1000 reactors / Midwest Gen, Blagojevich reach pollution deal / Behold, the carpet gasifier / AREVA casks green-lighted by NRC / Brookfield Power upgrades Oswego Falls / Korea fires up 50-MW landfill gas project / Alstom lands big Russian deal / POWER digest / Correction

-

O&M

Focus on O&M (February 2007)

The compliance clock is ticking / First-class maintenance in a developing country / Bypass losses squander big bucks / Revised operating procedures

-

Legal & Regulatory

The tyranny of the final, nonappealable condition

The financing of power generation projects increasingly depends on the execution of a long-term power-purchase agreement (PPA). A common prerequisite for considering a PPA to be “effective” is a “final and nonappealable” regulatory order approving it. Purchasing utilities justifiably insist on such certainty to immunize their PPAs from after-the-fact regulatory scrutiny and possible penalty. Unfortunately, […]