The global solar boom has introduced a new urgency around asset durability, performance, and risk. As utility-scale solar farms become more common, so do the invisible defects that compromise long-term generation and reliability. While traditional visual and infrared (IR) inspections are still a common practice, a more advanced diagnostic method is emerging as an invaluable tool for solar operators: electroluminescence (EL) testing.

Unlike surface-level assessments, EL imaging allows engineers to see inside the photovoltaic (PV) module itself. It allows them to identify microcracks, soldering defects, and manufacturing flaws that standard inspections commonly miss. These small imperfections often have large consequences. They can lead to power loss, shorten asset lifespan, and complicate warranty claims or insurance evaluations.

What Is EL Testing and Why Does It Matter?

Electroluminescence is a phenomenon in which a PV cell emits light when exposed to an electrical current. Because this emitted light falls in the near-infrared spectrum (~1100 nm), specialized short-wave infrared (SWIR) cameras are required to capture it. When combined with controlled power input and analysis software, EL imaging offers a highly detailed view of a module’s internal health.

What it’s doing is turning the PV cell into a light source instead of a power source. It flips the script on solar technology and helps engineers pinpoint defects before they evolve into performance or safety issues.

The science behind it isn’t new, but the application of EL in field diagnostics is advancing rapidly. Originally confined to lab-based quality control, EL imaging is now portable, faster to deploy, and more affordable, making it a viable tool for ongoing operations and maintenance (O&M) programs at scale.

What EL Testing Reveals

EL imaging is particularly effective when it comes to detecting:

- Microcracks caused by hail, handling, thermal cycling, or snow load.

- Broken interconnect ribbons and soldering faults.

- Cell contamination or uneven doping during manufacturing.

- Invisible damage from transit, installation, or maintenance.

In many cases, these types of defects never appear during initial inspections or energy performance checks. They only become visible once power loss, hot spots, or catastrophic failure occurs, by which point the financial cost is much higher. EL testing allows a chance to intercept those failures early.

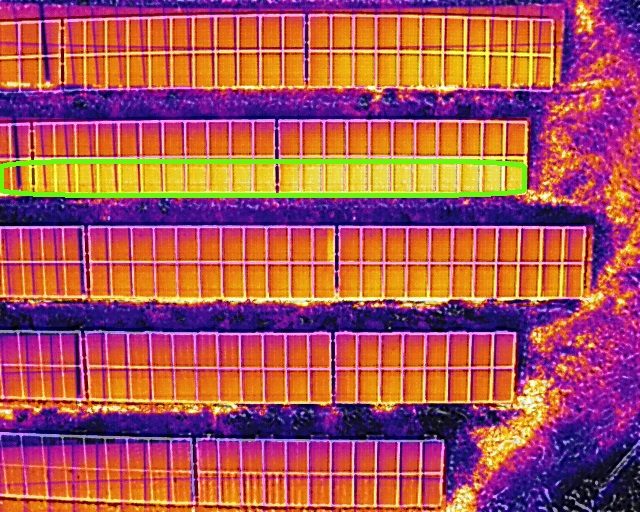

Unlike IR scans, which require modules to be energized and can only detect heat-based anomalies, EL testing can be conducted in a wider range of conditions, including at night or during low-light periods. It provides resolution at the cell level.

How EL Testing is Being Applied in the Field

EL imaging is increasingly used throughout the solar asset lifecycle:

- Pre-commissioning inspections help verify that modules were not damaged during shipping or installation.

- Post-weather event assessments can detect hail or wind-induced cracks that are not visible with infrared or visual checks.

- Warranty and insurance documentation is strengthened by EL scan data.

- Routine maintenance scans provide insight into long-term module degradation.

In post-storm inspections, EL testing has uncovered extensive internal cracking in panels that appeared undamaged to the naked eye. Detecting these hidden issues early gives owners the chance to pursue remedies before performance suffers.

There is also increased interest from insurance professionals who are turning to EL scans to support post-event claims. The clear, detailed imaging can help verify the cause and extent of damage, often expediting the claims process.

Operationalizing EL Testing: What it Takes

Performing EL testing in the field requires three main components:

- A controlled power supply capable of injecting short-circuit current into the module.

- A SWIR camera with the infrared filter removed.

- Image analysis software to align, crop, and evaluate scan results.

The setup is relatively mobile, with portable kits housed in a travel case. Some operators train internal technicians for periodic scans, while others bring in third-party forensic engineers for after-event diagnostics.

It’s important to note that EL imaging does require modules to be disconnected from the array and tested individually or in small groups. While this makes it less efficient than drone-based IR imaging for large fields, the added diagnostic accuracy is well worth the tradeoff, especially for targeted evaluations after an event.

Strategic and Regulatory Value for Stakeholders

For energy leaders and regulators, the benefits of EL testing go beyond defect detection. They include:

- Reduced unplanned outages by catching issues before they lead to failures.

- Better claim outcomes in post-disaster or warranty scenarios.

- Regulatory confidence through documented evidence of safety-focused practices.

- Support for grid resilience mandates as regulators increasingly scrutinize renewable reliability.

As engineers think about solar as critical infrastructure, the inspection tools used need to match the scale and precision of the investment. EL gives utilities a proactive strategy to maintain resilience.

In a future where climate volatility is increasing and solar installations are expected to double, preventive technologies like EL imaging will only become more essential. Policymakers and regulators may even begin incorporating EL scans into resilience assessments or disaster response protocols.

The Bottom Line: A Clearer Picture of Solar Reliability

EL testing isn’t a replacement for IR or visual inspections. It’s a complement; an early warning system that gives operators a chance to act before performance loss or system failure occurs. For organizations and professionals focused on optimizing solar system performance, EL testing offers a cost-effective way to detect what standard inspections can overlook.

When it comes to solar diagnostics, seeing the invisible is often the key to sustaining performance.

—Britton C. Hager, P.E., is a forensic engineer with Engineering Design & Testing Corp. (EDT) based in Philadelphia, PA, specializing in solar panel damage assessments and failure analysis across utility, industrial, and commercial energy systems nationwide.