|

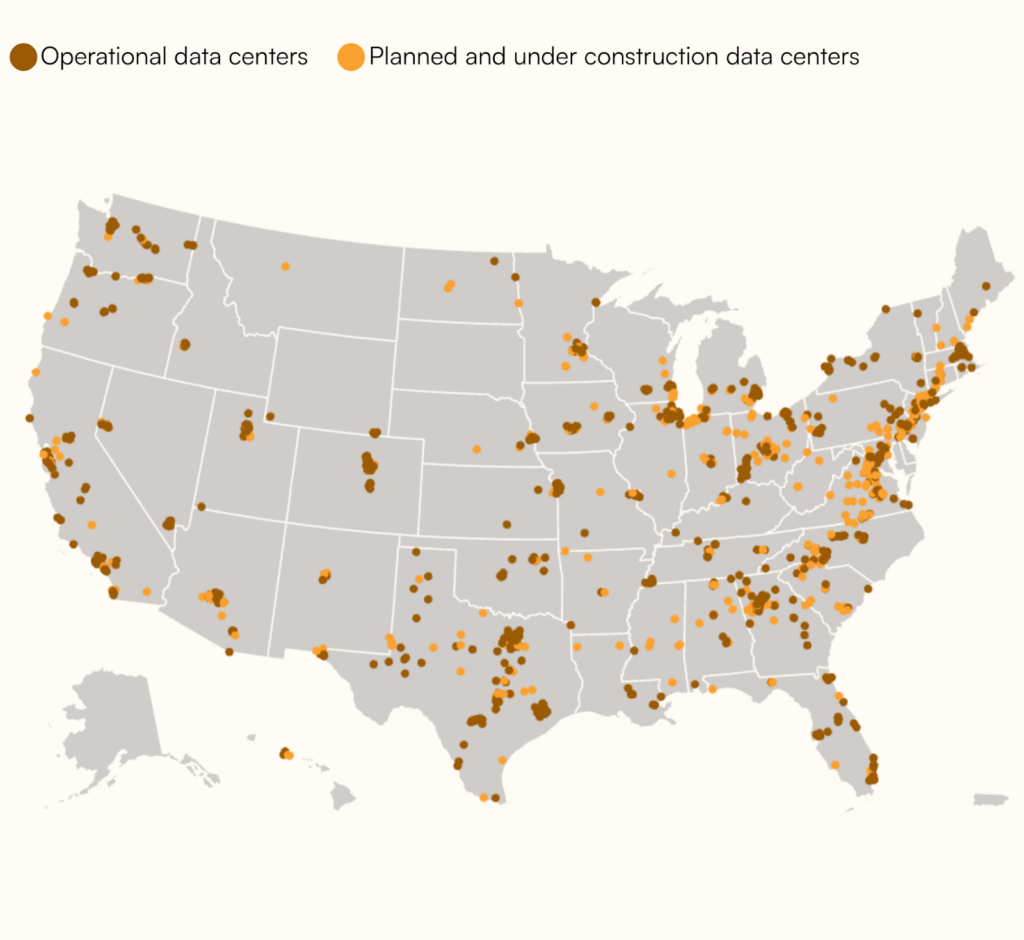

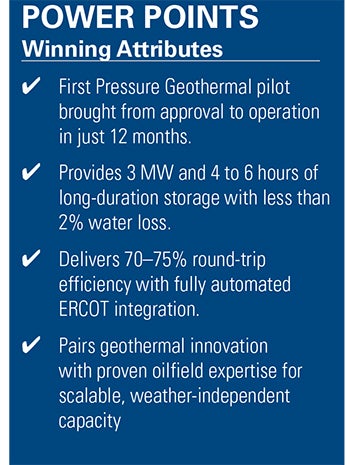

In just 12 months, Sage Geosystems and San Miguel Electric Cooperative built the world’s first pressure geothermal system. It is now poised to deliver long-duration, dispatchable storage for the Electric Reliability Council of Texas (ERCOT) as variable generation and data center demand surge.

In Christine, Texas—a town of barely 365 people an hour south of San Antonio—San Miguel Electric Cooperative Inc. (SMECI) is pulling off a transformation that will redefine rural generation. Borne out of efforts to bring reliable, affordable power to South Texas’s overlooked ranchlands and small towns, the member-owned cooperative built and commissioned a 391-MW mine-mouth lignite power plant at the Atascosa County site, tapping deposits from its own San Miguel Mine. For more than 40 years, that plant, the entity’s only unit, provided baseload power to 47 counties through a wholesale contract with member-customer South Texas Electric Cooperative (STEC), and functioning as a critical anchor in the Electric Reliability Council of Texas’s (ERCOT’s) South Load Zone.

While coal, fueled by locally mined lignite, has long been SMECI’s backbone, the cooperative has been working to ensure it can sustain its baseload responsibility while transitioning to cleaner resources, easing the early retirement of the lignite plant ahead of STEC’s 2037 contract expiry. “Unlike investor-owned utilities, we are operated by and for the people of South Texas in predominantly rural areas—regions that had historically been overlooked,” the cooperative notes on its website. “We have one simple goal: reliable power, not making a profit.”

That mission drove two landmark efforts last year: a first-of-its-kind geothermal partnership with Sage Geosystems to launch a Pressure Geothermal pilot and an application to the U.S. Department of Agriculture’s New Empowering Rural America (New ERA) program—which in December secured over $1.4 billion in grants and low-interest loans—to replace the lignite unit with 400 MW of solar and 200 MW of battery storage by 2027.

The geothermal pilot, SMECI Well #1, is the first piece of that vision to materialize. Moving from funding approval to “ready to store” in just 12 months, Sage completed drilling, fracture stimulation, surface-facility installation, and commissioning by August 2025. Leveraging innovative design, existing oilfield expertise, and streamlined permitting, the 3-MW/4–6-hour system has transformed a pioneering underground energy storage concept into a fully built asset in record time. While the project is still awaiting grid interconnection—currently slated for December 2025—the pioneering project has showcased a new model for firm, dispatchable capacity in ERCOT’s evolving grid, and is well worthy of this POWERTop Plant award.

First-of-a-Kind Geothermal Energy Storage

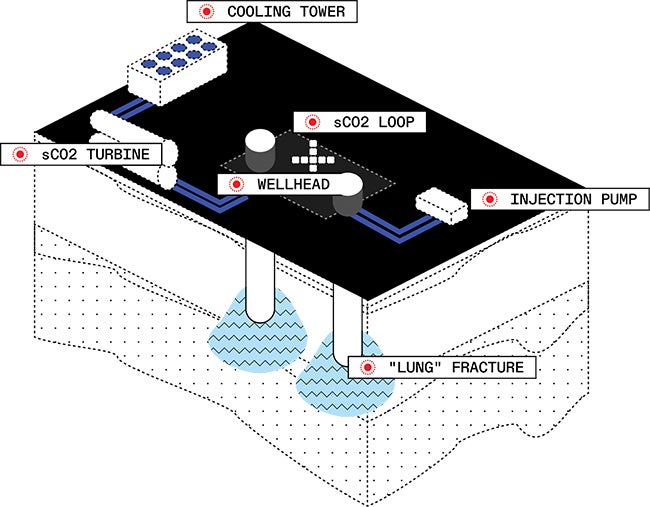

For Sage, the project marks the first commercial-scale deployment of its proprietary Pressure Geothermal System (GGS), a technology the company has been developing since its founding in 2020 by a team with more than 150 years of combined oil and gas experience. The system builds on lessons from a 2023 demonstration well in Starr County, Texas, which delivered up to 17 hours of discharge with minimal water loss and a round-trip efficiency of 70–75%, proving the concept’s ability to provide long-duration, dispatchable capacity (Figure 1), Brianna Byrd, a Sage Geosystems’ operations engineer told POWER.

|

|

1. This graphic illustrates Sage Geosystems’ Pressure Geothermal System, which uses a deep engineered “lung” fracture—a subsurface reservoir created in low-permeability rock—to store and release energy using, in this case, a supercritical carbon dioxide (sCO2) power system. Courtesy: Sage Geosystems |

“Sage’s proprietary energy storage technology functions much like pumped-storage hydropower (PSH), but upside down, with the ‘upper reservoir’ located deep underground rather than on top of a mountain,” Byrd explained. “We create a vertical fracture system in low-permeability rock that serves as an artificial reservoir.” To charge the system, water is pumped from a surface storage down the wellbore into the fracture, “inflating” the water under pressure like a balloon. And to discharge it, the pump is shut off, and the pressurized fracture system pushes water back up the wellbore. “At the surface, it drives a Pelton turbine and generator. A choke system modulates flow as pressure declines, ensuring steady power output until the predetermined volume of water is released from the well,” she said.

For pressure geothermal power generation, “the same principles apply, but the pressurized water is also heated by the surrounding hot rock,” Byrd added. “The heat is then converted to electricity using either a conventional Organic Rankine Cycle (ORC) or Sage’s proprietary supercritical carbon dioxide (sCO 2) power system. The water used to extract heat from the Earth is kept separate from the CO 2, which remains in a closed-loop system in the power plant.”

These innovations have yielded high efficiency and long-duration flexibility. “The round-trip efficiency (RTE) for Sage’s energy storage system is expected to be 70–75%, as we hold open the fractures with pressure, which reduces friction and energy losses,” Byrd said. “This efficiency will not degrade over time.” That performance is on par with pumped storage hydropower but without the geographic constraints. Lithium-ion batteries can achieve a higher RTE of 85–90%, she noted, but degrade over time with repeated cycling and exposure to high ambient temperatures.

Byrd also stressed that Sage’s energy storage technology is not intended to compete with lithium-ion batteries for short discharge durations. “However, for durations of more than five hours, when lithium-ion systems must be stacked and costs escalate, our levelized cost of storage (LCOS) is projected to be significantly lower,” she said. “Additionally, Sage’s solution eliminates fire hazards associated with batteries and avoids the raw material supply chain and recycling challenges tied to lithium-ion batteries, offering a lower lifecycle impact.”

In another benefit for drought-prone regions like Atascosa County, the design minimizes water loss—less than 2% in field testing—by keeping the fracture sealed and pressurized throughout operation. “The surface facility is designed to operate within a defined pressure window, between the fracture opening and the fracture extension pressure, to avoid uncontrolled fracture growth,” Byrd noted. “We continuously monitor pressure, flow rates, and volumes in real time. This data is integrated into an automated control system that adjusts pumping parameters to keep the system within safe operating limits.”

A Strategic Match in the Heart of ERCOT

Notably, the project is also entirely digitally automated to integrate seamlessly with ERCOT, a characteristic that is a growing imperative in the fast-moving market, which faces extreme weather, renewable swings, and a surging demand strain from data center and cryptocurrency mining. Sage plans to operate SMECI Well #1 as a merchant, buying and selling electricity into ERCOT’s South Load Zone. “It uses advanced control systems to manage charge and discharge cycles in real time, responding to grid signals and demand fluctuations,” said Byrd. “These smart grid and digital automation layers ensure efficient synchronization with the broader energy network, enabling fast response times, remote monitoring, and dynamic participation in grid dispatch.”

Notably, the project is also entirely digitally automated to integrate seamlessly with ERCOT, a characteristic that is a growing imperative in the fast-moving market, which faces extreme weather, renewable swings, and a surging demand strain from data center and cryptocurrency mining. Sage plans to operate SMECI Well #1 as a merchant, buying and selling electricity into ERCOT’s South Load Zone. “It uses advanced control systems to manage charge and discharge cycles in real time, responding to grid signals and demand fluctuations,” said Byrd. “These smart grid and digital automation layers ensure efficient synchronization with the broader energy network, enabling fast response times, remote monitoring, and dynamic participation in grid dispatch.”

For Sage, delivering its first commercial pilot in Texas also meant capitalizing on a favorable policy and permitting environment. “Texas clarified through legislation in 2023 that landowners own the geothermal heat, providing certainty for operators,” she said. “In addition, the Texas Railroad Commission, responsible for permitting geothermal wells, brings over 100 years of expertise in oil and gas permitting and can permit geothermal wells in weeks rather than months or years.”

The company credits its project implementation speed—from partnership to “ready to store” in just 12 months—to a combination of proven oil and gas expertise, an intentionally streamlined design, and Texas’s uniquely favorable permitting environment. Pressure geothermal draws on the full spectrum of oil and gas expertise: geoscience for evaluating and characterizing subsurface rock formations; engineering and operations for design, execution, project management, and cost control; and service providers for drilling, completions, and fracturing from established oilfield companies, Byrd explained.

“Most of the Sage Geosystems team comes directly from the oil and gas industry. The founders alone bring over 120 years of combined experience. Leveraging these proven technologies, tools, and skillsets allows Sage to scale immediately without having to reinvent equipment or retrain a new workforce, which is critical for next-generation geothermal and energy storage,” Byrd said.

Following grid interconnection of the SMECI energy storage system in December 2025, Sage plans to focus on drilling wells and building its second energy storage facility with a major utility. Work is meanwhile ongoing on its first commercial power generation facility as part of Meta Phase I, a partnership announced in August 2024 to deliver up to 150 MW of new geothermal baseload power for the social media company’s expanding U.S. data centers. The project is slated to be online in 2027. “We continue to advance partnerships with big tech hyperscalers, utilities, and the U.S. Department of Defense,” said Byrd.

Ultimately, Sage sees three clear use cases for its technology—energy storage, power generation, and district heating. “In the near term, we are prioritizing energy storage and power generation,” she said. “Energy storage can be deployed quickly, as demonstrated at our SMECI facility, which was built in about 12 months and directly enhances the performance and value of solar and wind assets. Power generation is in high demand for clean baseload capacity, particularly from data centers and military installations. With AI [artificial intelligence] driving explosive growth in data center demand, this need will only increase.” For now, “District heating is a largely European opportunity, where piping infrastructure is already in place and coal/biomass heat sources are being phased out. However, permitting timelines are longer, so we expect these projects to advance in the next couple of years.”

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).