Hydropower is among the most mature and reliable renewable energy technologies, but its dependability rests on thousands of tonnes of rotating equipment humming quietly for decades. Generators are at the heart of those units, and their performance hinges on bearings that carry enormous radial and axial loads. When a bearing fails, the result is not just noise or vibration—it can mean a forced outage that idles an entire turbine-generator set. Analysts note that bearing failures account for a large fraction of rotating machinery failures, with surveys of industrial machinery putting the figure between 40% and 90%. In hydropower units, thrust and guide bearings support a vertical shaft weighing tens of tonnes, so the stakes are even higher.

The costs of unplanned outages illustrate why operators care so much about bearings. An energy sector analysis estimated that unplanned downtime can cost hundreds of thousands of dollars per hour, and a forced outage lasting several hours can easily translate into millions in lost revenue. For utilities operating on tight margins or feeding power into competitive markets, avoiding unexpected bearing failures is just as important as improving efficiency.

Understanding Bearings in Hydropower Generators

Large hydropower generators typically have two main bearing types:

- Guide bearings positioned along the vertical shaft keep the rotor centered in the stator. These bearings usually have oil-lubricated pads that support radial loads.

- Thrust bearings at the top of the shaft support the combined weight of the rotor and turbine. They absorb axial loads and maintain precise axial clearances.

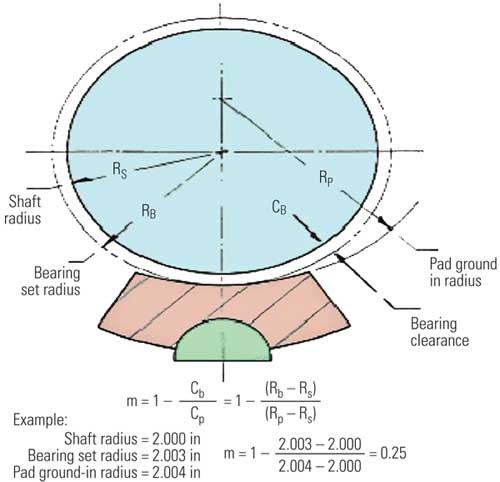

Both types may be segmented pad designs (such as tilting-pad thrust bearings) with Babbitt or polytetrafluoroethylene (PTFE)-faced pads. They rely on a stable oil film to prevent metal-to-metal contact and dissipate heat. Hydropower units often operate continuously for months between planned outages, so bearing surfaces must be robust and lubrication systems must keep oil clean and cool.

What Causes Bearing Failures?

Root cause analyses across industry show that misalignment is one of the most common underlying causes of bearing failures. An article on machinery reliability notes that misalignment is the root cause of most machine breakdowns, including bearing failures, and estimates that about half of machine failures are linked to misalignment. When shafts or housings settle or components are assembled improperly, the resulting angular or offset misalignment produces uneven loads on the bearing pads. Over time, this leads to fatigue, edge loading, and overheating. Other causes of bearing failure include:

- Lubrication Problems. Contaminated oil, water ingress, or incorrect lubricant viscosity can destroy the protective oil film, leading to metal-to-metal contact and rapid wear. Insufficient flow or blocked oil channels also starve pads of lubrication.

- Overloading or Transient Events. Sudden load changes during start-ups, shutdowns, or load rejection can exceed the bearing’s load capacity, causing plastic deformation or wiping of Babbitt surfaces.

- Material Defects or Manufacturing Errors. Imperfections in pad surfaces, improper machining, or poor-quality materials can initiate cracks or spalling.

- External Factors. Foundation settlement, concrete growth, and temperature variations can create misalignment or distortion that translates into bearing stresses.

Because bearings often respond to other problems in the system, investigating a failure requires looking beyond the bearing itself. As one reliability guide notes, misalignment and other subtle mechanical issues often manifest first in the bearings.

A Real-World Lesson: Repeated Thrust Bearing Failures

A notable example of bearing-related downtime comes from the Cataract hydroelectric plant in Maine, which was operated by FPL Energy at the time. The 6.65-MW turbine-generator experienced repeated thrust-bearing failures over several decades. According to a detailed case study, the thrust bearing failed eight times between 1959 and 2005. Each failure led to a forced outage and costly repairs.

Engineers suspected misalignment because the failures always occurred on the same side of the bearing. Investigation revealed that concrete growth and distortion of the foundation caused the rotor to tilt slightly, producing uneven loads on the thrust pads. Moreover, the original bearing design lacked sufficient load capacity to accommodate occasional overloads. During a major retrofit, the operators replaced the conventional Babbitt-faced bearing with an eight-pad, spring-supported PTFE thrust bearing. The new design allowed pads to tilt and equalize loads, and its PTFE surfaces tolerated higher unit loading. The retrofit eliminated misalignment issues and no thrust bearing failures occurred through at least the next four years of operation. This case shows how misalignment and inadequate design can cause repeated failures and how careful root cause analysis leads to lasting solutions.

How Root Cause Analysis Uncovers Bearing Problems

Root cause analysis (RCA) is a structured method for identifying why a failure occurred and preventing it from recurring. In hydropower plants, an effective RCA process for a bearing failure typically involves the following steps:

- Define the Problem Clearly. Gather information on when the failure occurred, what symptoms were observed (vibration, temperature rise, oil contamination, etc.), and what was happening in the plant at the time.

- Collect Data from Multiple Sources. Vibration measurements, oil analysis results, temperature logs, alignment records, operational data (loads, gate openings, etc.), and maintenance history all provide clues. Operators often rely on portable vibration monitors and oil sampling during inspections. When available, permanently installed sensors can stream data continuously.

- Reconstruct the Event Timeline. Determine when anomalies first appeared, how quickly conditions deteriorated, and whether any upstream events (such as load changes or maintenance activities) preceded the failure.

- Identify Potential Failure Modes and Causes. Common techniques include fishbone (Ishikawa) diagrams, “5 Whys” questioning, and fault-tree analysis. For a bearing failure, analysts might explore misalignment, lubrication issues, contamination, material defects, or improper installation.

- Test Hypotheses and Confirm the Root Cause. This may involve inspecting components, measuring alignment, analyzing oil chemistry, or simulating loading conditions. For example, in the Cataract plant case, pad inspections and foundation measurements confirmed misalignment.

- Recommend Corrective Actions. Depending on the cause, solutions could include realigning the shaft, redesigning the bearing, improving lubrication systems, or adjusting operational procedures. It is also critical to address the upstream cause (such as foundation settling) to prevent recurrence.

Carrying out RCA requires collaboration among mechanical engineers, maintenance crews, and plant operators. However, the process is often hampered by fragmented data. Vibration logs may reside in one system, oil analyses in another, and maintenance records in spreadsheets. Without a unified view, engineers spend more time gathering data than analyzing it. Industrial artificial intelligence (AI) platforms, such as Cognite, can solve this problem by unifying the data and providing access to multiple different users all at once.

Digital Twins and the Value of Integrated Data

Hydropower operators are increasingly turning to digital twins to streamline root cause investigations and shift toward predictive maintenance. A digital twin is a virtual representation of a physical asset that stays synchronized through live data streams. The Pacific Northwest National Laboratory’s (PNNL’s) research into digital twins for hydropower notes that these models use sensor data, historical operating data, maintenance records, and simulation tools to replicate the behavior of turbines and generators. By integrating data from multiple systems, digital twins provide a comprehensive, real-time view of asset health.

The PNNL work emphasizes that digital twins enable predictive maintenance, where analytics and simulation are applied to sensor data to predict future performance and identify anomalies before they lead to failure. In the context of bearings, a digital twin can combine vibration signatures, temperature trends, oil chemistry, and historical failure modes to detect early signs of misalignment or lubrication degradation. When a deviation is detected, operators can schedule a planned shutdown rather than risk a forced outage.

Hydropower Operators Put Integration into Practice

A practical example of data integration comes from Hafslund Eco, a Norwegian hydropower producer. In a recent project, the company fed live sensor data and alarm signals from their 250-MW Nes plant into Cognite Data Fusion, an AI-ready platform that links operational data with maintenance records and engineering diagrams. Engineers built dashboards to track start-up sequences and monitor key parameters. When anomalies occur, the system notifies operators and displays relevant historical data. According to the company, having a unified view of operational data has helped them spot abnormal conditions early and avoid forced outages. For a large unit like Nes, every hour of avoided downtime translates into significant revenue savings.

Importantly, Hafslund’s team did not adopt digital tools as a replacement for engineering judgement. They used Cognite Data Fusion to reduce the time spent gathering data, allowing experts to focus on analysis. By contextualizing sensor data with maintenance logs and alarm histories, they were able to understand events in minutes rather than hours. This demonstrates how integrated data platforms can support, rather than supplant, human expertise.

Making RCA More Effective with Integrated Data

Bringing disparate data sources together is not just a technology challenge; it is a process transformation. To make RCA more effective and prevent bearing failures, hydropower plants can take several practical steps:

- Improve Data Quality at the Source. Ensure that vibration probes, temperature sensors, and oil quality monitors are calibrated and working. Capture baseline measurements after overhauls so that deviations can be detected.

- Adopt a Central Data Hub. Use a platform (commercial or custom) that can ingest supervisory control and data acquisition (SCADA) data, historian data, maintenance records, and engineering drawings. Contextualization—linking each sensor tag to the correct equipment and maintenance history—allows engineers to quickly retrieve relevant information.

- Implement Condition Monitoring and Analytics. Apply machine learning models or rule-based analytics to identify abnormal patterns in vibration or temperature. But avoid black box approaches; ensure that analysts understand why a model flags a condition so they can interpret it correctly.

- Develop Digital Twins of Critical Components. Start with high-value assets such as turbine generators. Use the twin to simulate misalignment scenarios or lubrication degradation and compare with real sensor data.

- Train Personnel in Both Maintenance and Data Analysis. Mechanics and operators should understand the significance of data trends, while data scientists must understand the physical system. A cross disciplinary culture is essential.

Maintaining Hydropower Bearings: Best Practices

Even with sophisticated analytics, good engineering practices remain the cornerstone of bearing reliability. The following tips can help prevent bearing problems:

- Ensure Proper Alignment. Perform precision shaft alignment during installation and after major overhauls. Check for foundation settlement or concrete growth periodically, and correct soft foot conditions. As the misalignment article stresses, treating misalignment early prevents excessive stresses on bearings, seals, and couplings.

- Maintain Lubrication Systems. Keep oil reservoirs clean, monitor oil temperatures and pressures, and sample oil regularly for contamination or degradation. For thrust bearings with tilting pads, ensure that the loading springs or pivot points are functioning.

- Monitor Continuously. Permanent vibration and temperature sensors can detect anomalies that portable measurements miss. When trending data, look for slow increases in vibration amplitude or bearing metal temperatures, which often precede failure.

- Plan Inspections During Outages. During scheduled outages, inspect bearing pads for signs of wiping, cracking, or uneven wear. Measure the oil film thickness and check for pad tilting. Inspect alignment and foundation conditions at the same time.

- Learn from Failures. When a bearing fails, avoid simply replacing it and returning to service. Conduct a thorough RCA, involve experts from different disciplines, and implement corrective actions beyond the bearing itself.

Reliable Hydropower Requires Both Engineering and Data

Bearing failures remain a leading cause of forced outages in rotating machinery, and hydropower generators are no exception. Factors such as misalignment, lubrication problems, and design deficiencies can all contribute, but it is often a combination of mechanical issues and operational conditions that brings a bearing to failure. The Cataract plant’s repeated thrust bearing failures show how misalignment, if left unresolved, can plague a unit for years. Conversely, integrating data and redesigning the bearing solved the problem.

Today’s hydropower operators have new tools to tackle these challenges. Digital twins and integrated data platforms allow engineers to see a complete picture of asset health. Practical implementations, such as Hafslund Eco’s use of Cognite Data Fusion, demonstrate that AI-ready data can shorten root cause investigations and prevent unplanned outages. Nevertheless, success depends on good maintenance practices, cross disciplinary collaboration, and careful attention to fundamentals.

Hydropower has powered economies for more than a century; keeping it reliable for the next century will require both sound engineering and smart data integration. By understanding why bearings fail and leveraging modern tools to detect and prevent those failures, operators can reduce downtime, improve safety, and ensure that clean, renewable power continues to flow.

—Rafed Hossain is a senior technical director with Cognite.