Water

-

O&M

Focus on O&M (April 2008)

Tag-teamed seawater cleanup; New cooling towers to improve river’s health; Back to school

-

Coal

New coal plant technologies will demand more water

Population shifts, growing electricity demand, and greater competition for water resources have heightened interest in the link between energy and water. The U.S. Energy Information Administration projects a 22% increase in U.S. installed generating capacity by 2030. Of the 259 GW of new capacity expected to have come on-line by then, more than 192 GW will be thermoelectric and thus require some water for cooling. Our challenge will become balancing people’s needs for power and for water.

-

O&M

Focus on O&M (March 2008)

New CIP standards leave questions unanswered/Solving common analyzer problems/Qualifying rebuild shops

-

O&M

Maintaining water sample panels improves plant availability

Even comedian Rodney Dangerfield got more respect than many plant water sample panels do. But power plants ignore sample panels at their peril. Those sample panels, and readings of the on-line analyzers they support, identify when multi-million-dollar systems have a problem that demands immediate attention.

-

Water

Benefits of evaporating FGD purge water

In the U.S. and the European Union, scrubbers are installed on all new coal-fired power plants because their technology is considered the best available for removing SO2. A zero-liquid-discharge system is the best technology for treating wet scrubber wastewater. With the future promising stricter limits on power plants’ water use, ZLD systems that concentrate scrubber purge streams are sure to become as common as ZLD cooling tower blowdown systems.

-

Water

Costlier, scarcer supplies dictate making thermal plants less thirsty

The Energy Information Administration estimates that U.S. thermoelectric generating capacity will grow from 709 GW in 2005 to 862 GW in 2030 to help meet annual demand increases of 2%. The makeup and cooling water needed by plants generating that increased capacity certainly won’t be available from withdrawal sources, so plant developers and owners will have to apply water-stingy technologies plantwide. As is usually the case, conservation saves money as well as the environment. Here’s a thumbnail economic analysis of some solutions to the water problem.

-

Water

Forgotten water: Stator cooling water chemistry

Stator cooling water treatment is often ignored—until the generator fails. Proper treatment and monitoring is essential to keeping the copper in your stators, where it belongs.

-

O&M

Focus on O&M (September 2007)

Replace pumps, cut repair bills / New bolts show their stress level / Up a certain creek, without a filter / Hang up those cables and hoses

-

Water

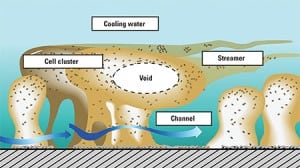

Biofouling control options for cooling systems

The infrequent or improper introduction of biocides into a plant cooling system may make fouling within it worse, by creating thick biofilms that can foster corrosion, reduce heat transfer, and increase water pumps’ operating costs. At the other end of the spectrum, overuse of biocides can waste expensive chemicals. Optimizing the quantity, frequency, and type of dosage can improve both the health of a cooling system and its plant’s bottom line.

-

Water

Reclaimed cooling water’s impact on surface condensers and heat exchangers

Because water is more precious than power in many regions of the U.S., plant designers are more frequently specifying the use of treated wastewater for plant cooling. Using "gray water" poses its own challenges for critical service equipment like condensers and heat exchangers. Some problems—like corrosion—are familiar, whereas others are rare. But so far, none has been a match for the ingenuity of multidisciplinary design experts.