Plant Design

-

Coal

Illinois Lawmakers Block Clean Coal Plant

Ringing what may be the death knell for the $3.5 billion Taylorville IGCC project, the Illinois Senate voted 33-18 in early January against authorizing construction of a coal gasification and power generating plant proposed in the state by Tenaska.

-

Coal

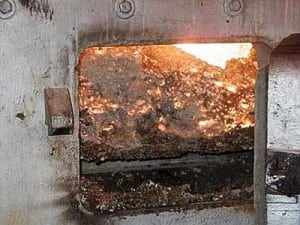

EPA Regulations Accelerate Industry Shift from Wet to Dry Bottom Ash Solutions

Energy efficient and environmentally responsible dry bottom ash technologies will soon be required by regulation. Progressive companies will bring their plants into compliance early because it’s a good business strategy. Here are your compliance options.

-

Coal

Comparing the Value of Single- and Double-Layer Insulation on Boiler Walls

Boiler insulation practices have moved from using a single layer to a double layer of the same total thickness in recent years. However, this dual-layer trend has a downside: higher installation costs and the opportunity for contractors to cut corners when installing insulation. It’s time to return to using single-layer insulation on power boilers.

-

O&M

Power 101: Flue Gas Heat Recovery in Power Plants, Part I

Every power engineer must have a firm grasp of the rudiments of how fuel is processed to produce electricity in a power generation facility. With this article, we begin a series of Power 101 tutorials that present these fundamentals in a clear and concise way. First up are the essentials of recovering heat from flue gas.

-

Coal

New York Proposes Costly Retooling of Power Plant Cooling

In a move that could cost the state’s electricity generators an estimated $8.5 billion, New York regulators [have] issued a draft policy that would require the installment of closed-loop cooling systems at two dozen large power plants in the state, including oil, coal, nuclear and natural gas generators, to reduce fish kills and other harmful effects to wildlife in the water bodies that supply the plants’ cooling water.

-

O&M

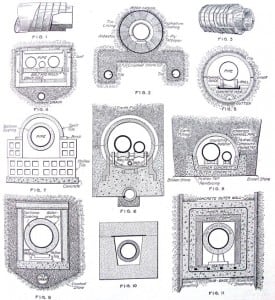

Conveyor Upgrades Increase Plant Availability, Reduce Airborne Dust

The loading and discharge of conveyor belts is the area where many, if not most, of the problems in solids conveying occur. Fortunately, a new technology provides chutes to accomplish conveyor loading and discharge without blockages while minimizing the dust generated: engineered-flow transfer chutes.

-

O&M

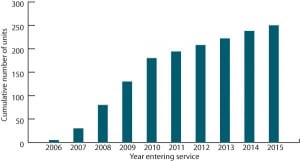

World’s Largest Circulating Fluidized Bed Boiler Begins Commercial Operation

When the Åagisza power plant began commercial operation in late June 2009, it marked the beginning of a new era in the evolution of circulating fluidized bed (CFB) technology. At the heart of this 460-MW plant is the world’s largest CFB boiler, which is also the world’s first once-through unit supercritical CFB boiler.

-

O&M

Leading-Edge Conveyor Technologies Reduce Dust Emissions

Reducing dust from coal conveyors has moved from a housekeeping chore to a safety challenge, especially with Powder River Basin coals. Here’s what you need to know about the latest coal-handling system design.

-

Coal

UK Sets Binding Carbon Cuts; Requires CCS at Coal Plants

The UK has all but doomed new coal-fired capacity by simultaneously setting binding carbon reduction goals and by requiring carbon capture and sequestration (CCS) of carbon emissions from new mid-size coal-fired power plants. Existing plants will also be required to retrofit their plants when CCS technology is demonstrated, now estimated to happen by 2020.

-

Coal

FirstEnergy Retools Coal Plant to Burn Biomass

FirstEnergy has announced plans to repower two coal-fired units at the R.E. Burger plant to burn biomass. Conversion of the two units, expected to be completed by 2012, gets the utility off the hot seat with the EPA for alleged Clean Air Act violations.

-

O&M

A New Era in Power Plant Control Performance

Recent improvements in the performance of steam power plants have been achieved with advanced computerized controls. These new control schemes not only reduce fuel consumption and make the plant much more responsive, but they also can significantly decrease start-up commissioning time and cost.

-

O&M

Dominion Solves Mt. Storm’s Fuel-Handling Problems with Improved Coal Silo Design

Many coal-fired power stations built before 1980 were designed for handling relatively easy-handling lump coal. If your plant’s bins, bunkers, and silos aren’t up to dealing with today’s range of more variable coal properties, this case study shows one way to minimize coal flow problems.

-

Coal

Designing New Composite Stack Liners

The 200-MW Dallman Unit 4 under construction in Springfield, Ill., is expected to cost approximately 20% less to operate per megawatt-hour than the most efficient of the three existing Dallman units. A composite stack liner is one element enabling that cost savings.

-

Coal

Custom FRP Trench Drains Speed Up FGD System Installation

The flue gas desulfurization process requires the use of aggressive liquids that significantly shorten the life of typical construction materials such as metals and concrete. That makes fiberglass-reinforced plastic (FRP) the material of choice for many components in a typical flue gas desulfurization (FGD) system.

-

Coal

Low-NOx Retrofit for Firing Coal/Petroleum Coke Blends

Replacing existing, older-generation controlled-flow split-flame burners on Unit 1 at the Seminole Generating Station with Foster Wheeler’s new low-NOx burners and overfire air additions reduced NOx emissions. This case study provides all the details and post-installation test results.

-

Coal

A Fieldbus Primer

Many automation engineers are coming face to face with real fieldbus applications for the first time. Fieldbus (the use of digital communications networks for distributed instrumentation and control) is a wonderful technology with many benefits, but fieldbus installation requires some additional considerations over and above normal 4-20 mA projects. In this article, I present some of those issues and show you how to deal with them.

-

Coal

Designing Material-Handling Systems for FGD Projects

Reducing NOx, SO2, and other air pollutants continues to be a challenge for the power generation industry. The technologies are well-understood, but the devil is always in the details, especially when a complex treatment system is retrofitted to an existing plant.

The most common method for reducing SO2 from plant emissions is the conventional lime- and limestone-based flue gas desulfurization (FGD) system. Material-handling systems for limestone and gypsum present specific challenges and opportunities that differ from those of coal-handling systems. This article looks at factors to consider before and during the design of a new material-handling system. The choices you make about these many variables will determine the cost and longevity of your system.

-

Coal

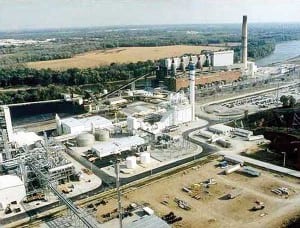

From Plan to Plant: The Struggle to Make “Clean Coal” a Reality

In early June, New York Gov. David Paterson proclaimed that his state would commit $6 million to buttress a carbon capture and sequestration (CCS) viability study for the development of a new 50-MW clean coal plant in Jamestown, in western New York. The circulating fluidized-bed (CFB) project, which would use pure oxygen to combust coal and subsequently capture and sequester 90% of emitted carbon dioxide (CO2), would be “the first of its kind in the world” and could potentially enable New York firms to launch exports of the technology worldwide, Paterson promised.

-

Coal

The Future of Coal Power: Development and Siting Obstacles for New Coal Plants

In recent years, Sargent & Lundy has evaluated many potential sites for new coal-fueled generation. Some of the sites studied were lands adjacent to existing power plants (brownfield sites); others were undeveloped greenfield sites. The numerous technical, environmental, economic, and regulatory issues that bear on power plant siting generally apply to both brownfield and greenfield […]

-

Coal

The Coal Patrol: Growth in PRB Coal Use Will Be Fueled by New Projects

Production from Wyoming Powder River Basin (PRB) coal mines ended last year with a increase of only about 1.1%, reflecting a record 451.3 million tons, according to the Department of Energy’s Energy Information Administration. Production of PRB coal spiked with a record 10% growth in 2006 following two derailments on the PRB’s main triple-track line […]

-

Coal

FutureGen: FutureGen Finds a Home But Can’t Pay the Mortgage

The FutureGen Industrial Alliance Inc. selected Mattoon, Ill., as the site of the $1.8 billion FutureGen project just before Christmas, but the plant may never move off the drawing board.. FutureGen, the proposed prototype of a near-zero-emissions coal plant, is to demonstrate advanced technologies for coal gasification, electricity production, emissions control, CO 2 capture and […]

-

Coal

IGCC: IGCC’s Future Hinges on a Workable Carbon Framework

Integrated gasification combined-cycle (IGCC) technology, a process of gasifying coal that allows the capture of carbon dioxide emissions, has tremendous potential for meeting future baseload generation demand. Though it is one of the leading alternatives for producing clean power from coal, IGCC faces a precarious future due to rising capital costs and regulatory uncertainty. We’re […]

-

Coal

Advanced Combustion: Cofiring Coal and Biomass or Non-Recyclable Waste

Burning biomass or nonrecyclable commercial, municipal, or industrial waste along with coal represents one of the nearest-term and lowest-cost options for reducing carbon dioxide (CO 2) emissions from existing utility power plants. At more than 150 plants worldwide, doing so has produced lower CO 2 emissions than burning coal alone. Indeed, with the number of […]

-

Coal

Coal Plant O&M: Retrofit Flyash-Handling System Pays Dividends

Like many older coal-fired plants, Westar Energy’s Jeffrey Energy Center (JEC) was built with traditional, pneumatic flyash-handling and removal systems. Such systems collect flyash in hoppers attached to the bottom of a unit’s electrostatic precipitator (ESP) and/or baghouse. Periodically, the hoppers are emptied into tanks and the flyash is conveyed away for disposal or beneficiation. […]

-

Coal

Safety: Detecting Fires on PRB Coal Conveyors

All conveyor systems are at risk of fire caused by the ignition of transported materials or equipment failure. But the propensity of Powder River Basin (PRB) coal to self-ignite introduces an exceptional hazard requiring special fire prevention and automatic detection and suppression efforts. To that end, this article discusses the technologies of linear heat detection […]

-

Coal

Speaking of Coal Power: BACT to the Future

This August, Peabody Energy’s 1,600-MW Prairie State Energy Campus project in Illinois won a major federal appeals court decision, removing the last obstacle to groundbreaking. The six-year regulatory review process ended with an unsuccessful Sierra Club challenge to the $2.9 billion project’s air permit. The decision is sure to reverberate across the nation, and I […]

-

Coal

Coal Plant O&M: How Switching to PRB Lowered O&M Costs

Lansing Board of Water & Light (LBW&L), which has generated electricity since 1892 and steam since 1919 in mid-Michigan, primarily serves the city of Lansing’s business district and all state government buildings in the downtown area. But one of the municipal utility’s plants, Moores Park, has an additional and very important steam customer: General Motors’ […]

-

O&M

Plant Economics: The Impact of Shortages on FGD Prices

Since ratification of the Clean Air Act (CAA) in 1970, U.S. utilities have made steady efforts to install pollution control equipment to curb power plant stack emissions. The CAA Amendments of 1990 raised concerns at the time about the industry’s ability to install a large number of flue gas desulfurization (FGD) systems, or scrubbers, in […]

-

Coal

The Coal Pile: Steam Blast Rocks Big Apple

This July, an underground steam pipe near Manhattan’s Grand Central Terminal ruptured and spewed a scalding brown geyser of steam and debris higher than the nearby 77-story Chrysler Building. The blast, which injured 30 people, created a 40-foot crater at street level that swallowed a tow truck. A similar explosion in 1989 killed three people. […]

-

Coal

The Coal Patrol: Coal to Synfuels: Deal or No Deal?

Synfuels’ political bubble has burst in Washington, but the market may step in where Congress fears to tread. When coal industry interests, in the form of the CTL Coalition, got a bill with strong federal support for coal-to-liquids technology before the Senate this spring, it appeared that the political skids were greased for some kind […]