O&M

-

O&M

Securing continuous mobile data connections

For busy staff in the field, nothing is more frustrating than having laptop computers or smart phones crash due to lost connections when those devices lose wireless coverage. Often, important data is obliterated and workers have to waste precious time reentering the lost information. The irony is that wireless data connections, which are increasingly being […]

-

O&M

JCP&L’s SCADA-controlled adaptive relay scheme saves 25 SAIDI impact minutes

In 2005, Jersey Central Power & Light (JCP&L), a subsidiary of Akron, Ohio – based FirstEnergy Corp., initiated a project to identify protection system improvements that could be made to proactively combat wind- and lightning-related weather events that create sustained power outages (Figure 2). JCP&L determined that these changes had the potential to improve the […]

-

O&M

Managing software life-cycle issues

Software ranges from shrink-wrapped products available “off the shelf” to custom corporate implementations of enterprise systems that require sessions with shrinks to keep everyone sane. Regardless of its complexity, every piece of software a plant uses, or interfaces to, poses critical issues that require life-cycle management. Although functionality has always been the chief specification for software, plants must pay far more attention to long-term quality issues. These two concerns are often at odds with each other.

-

O&M

Repairing low-pressure rotors with cracked blade attachments

An increasing number of low-pressure steam turbines—especially at supercritical fossil units—have experienced stress corrosion cracking in the blade attachment region of their low-pressure rotors. Approaches to solving this problem range from redesign of the attachment and blade replacement to in-situ weld repair. Regardless of the procedure selected, the solution must completely restore the turbine performance while minimizing outage duration.

-

O&M

Entergy’s “big catch”

Entergy christened its Performance Monitoring and Diagnostic Center several years ago to leverage the expertise of its most senior operators and technicians across the company’s entire fleet of plants. The center also makes use of advanced software tools that increase plant availability and reliability by identifying faults before they become major, unplanned outages. The center paid for itself for years to come with a single “big catch” last year.

-

O&M

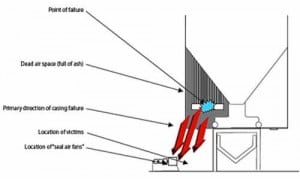

Anatomy of a Boiler Failure—A Different Perspective

The power industry’s operating and maintenance practices were held up to intense regulator and public scrutiny when on November 6, 2007, a Massachusetts power plant’s steam-generating boiler exploded and three men died.

-

O&M

The Low-Down on Low-Alloy Filler Metals

Chromium-molybdenum (chrome-moly) pipe has become a standard in the power generation industry, not only because of its corrosion resistance and high-temperature strength, but also for its cost-effectiveness. In many applications, it is a viable alternative to a more costly stainless steel pipe.

-

O&M

Hill Backing New FERC Powers on Grid Cyber Attacks

Spurred on by a recent audit showing widespread utility noncompliance with voluntary recommendations meant to protect the grid from cyber attacks, key lawmakers have unveiled plans to give the Federal Energy Regulatory Commission (FERC) broad powers to enact new mandatory measures to close vulnerabilities in the U.S. bulk power system to potentially devastating computer-launched assaults.

-

O&M

Focus on O&M (September 2008)

Tackling substandard water sources / Control abrasive wear in scrubber piping / Sensors and final control elements

-

O&M

Put a lid on rising chemical costs

News reports tell us that rapidly growing economies, such as China’s, are importing more oil and raw materials each year, thereby pushing up commodity prices on the world market. One of the side effects of rising commodity prices is considerable increases in the cost of water treatment chemicals. Don’t be tempted to skimp on chemicals to save a buck but risk catastrophic damage. In the words of NASA’s former flight director, Gene Kranz: “Failure is not an option.”