O&M

-

O&M

Increasing Generation Ramp Rate at Morgantown Generating Station’s Coal-Fired Units

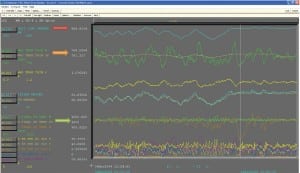

At Morgantown Generating Station, plant personnel used innovative methods to combine model predictive control with distributed control system–based process control algorithms to improve waterwall temperature control and main steam temperature control and to enhance unit ramp rate capability. The previous heat rate and NOx optimization performance gains were retained. Focusing beyond basic loops of feedwater, air, and O2, the project considered issues such as PID controller override configuration and limitations. The techniques used to overcome these challenges improved unit ramp rate capability beyond any previous unit performance.

-

O&M

Continuous SO3 Monitoring Can Reduce Sorbent Consumption

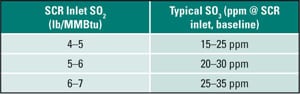

An unintended consequence of employing selective catalytic reduction and wet flue gas desulfurization to reduce nitrogen oxide and sulfur dioxide levels at coal-fired power plants has been unwanted sulfur trioxide (SO3) emissions. Picking the right sorbent in the right amount can eliminate that problem.

-

O&M

New Tools for Diagnosing and Troubleshooting Power Plant Equipment Faults

The Electric Power Research Institute has developed a pair of diagnostic tools that combine and integrate features from multiple sources of plant information. The Diagnostic Advisor and the Asset Fault Signature Database will improve diagnostics for and troubleshooting of equipment faults by providing a holistic view of the condition of plant equipment.

-

O&M

EPRI Identifies Four Breakthrough Technologies for 2011

The Electric Power Research Institute (EPRI) has identified four breakthrough technologies and funded them through its Strategic Research and Development Portfolio. EPRI expects to accelerate development of these innovations because they are likely to have significant effects on how electricity is generated and delivered.

-

O&M

Exelon Enjoys Benefits of Online Transformer Monitoring

In all of these cases, frequent oil analysis monitoring and preestablished action plans were able to allow for transformer replacement before the occurrence of a catastrophic failure. Exelon’s experience, as well as that of other power utilities across the grid, has spawned a report by the Institute of Nuclear Power Operations (INPO) of Atlanta, Georgia, that recommends that performance monitoring and trending be applied to all large transformers in order to establish a baseline for transformer maintenance strategies.

-

O&M

Selecting a Specialty Accumulator

Sudden bumps and shocks are great fun when you are off-roading or are riding on a rollercoaster. But when you are operating a piece of equipment, you want it to be running as smoothly as a Cadillac rolling down the interstate. Sudden changes in pressure produce vibration, cavitation, and water hammer and generally lower the lifespan and reliability of fluid systems.

-

O&M

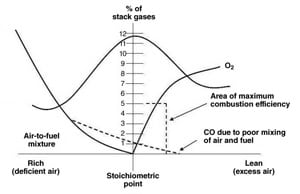

Flue Gas Analysis as a Furnace Diagnostic Tool

Combustion flue gas analysis has been used to optimize the boiler air/fuel ratio for decades. Measuring the amount of excess oxygen and/or carbon monoxide in combustion flue gases gives an indication of boiler efficiency and, thereby, plant operating economics. New sensors make those measurements simple and accurate.

-

O&M

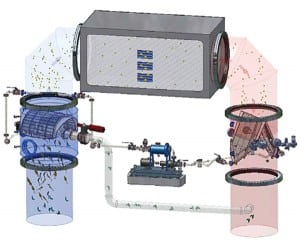

Keeping Condensers Clean

The quality of the cooling water intake and the amount of debris in that water affects the operation and performance of the condenser and therefore the thermal performance of the typical steam plant.

-

O&M

Expanding the Use of Predictive Maintenance as a Business Strategy

The Linde Group is a world-leading gases and engineering company operating in more than 100 countries. It’s no surprise that the company uses a variety of advanced monitoring techniques and equipment to keep its plants operating reliably. In the U.S. and UK particularly, Linde plants have used online machine condition monitoring for a number of years. At its Shanghai headquarters, Linde has formed a large and impressive remote operations center where it monitors and tracks the process operations of all its major gas plants in China 24 hours a day.

-

O&M

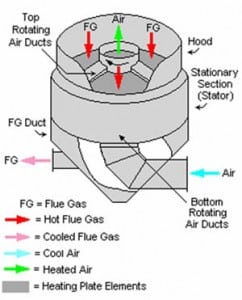

Power 101: Improving the Performance of Boiler Auxiliaries, Part I

Boiler auxiliary equipment often receives no respect for the role it plays in maintaining efficient boiler performance. In this second installment of our Power 101 series, we examine the design and performance of the air preheater.