O&M

-

O&M

Steam Turbine Cleaning Using Chemical Foams

In the May issue, we discussed the importance of either preventing copper plating of the high-pressure (HP) steam turbine rotor or finding a good foam or mechanical removal means of restoring lost efficiency. In that article we noted that “copper deposits typically form on the stationary nozzle block or first-stage stationary blades” and that those deposits usually result in a steam turbine loss of capacity at a rate of about 2 to 3 MW per month. We also stated that the “general rule of thumb is that there is a reduction of about 1 MW of generating capacity for each 1 to 2 pounds of deposit that accumulates on the HP turbine.

-

O&M

Predictive Maintenance That Works

This is the fourth in a series of predictive maintenance (PdM) articles that began in the April “Focus on O&M” with an introduction to PdM as a process whereby maintenance is performed based on the condition of the equipment rather than on a predetermined interval. In the May and July issues, we began exploring specific PdM techniques, such as motor-current signature analysis and oil analysis.

-

O&M

Optimizing Condenser Tube Selection

Selecting the most economical tube for a new condenser, or the retrofit of an existing one, is much more complex than mere price shopping. Each material has unique performance characteristics that affect the operating economics of the entire plant. A case study illustrates the importance of carefully choosing the tube material that is right for your plant.

-

O&M

Enhanced Capture of Mercury Using Unique Baghouse Filter Media

Several states have already instituted mercury emission limits in expectation of tightening mercury emission rules that will require reductions of up to 91%. Coal-fired plants searching for an economical way to meet the new limits may need to look no further than replacing their baghouse filter elements.

-

O&M

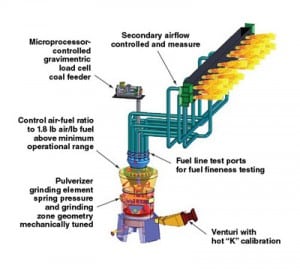

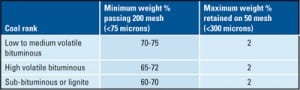

Pulverizers 101: Part II

Pulverizers prepare the raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of this three-part report, we examined the essentials of pulverizer design and performance. In the second part, we discuss the importance of fuel fineness. In the final article, we will discuss the importance of air and fuel measurement.

-

O&M

Improved Coal Fineness Improves Performance, Reduces Emissions

Utilizing engineering ingenuity and today’s developing computational fluid dynamics tools, a new classifier design is now available that significantly improves fineness from pulverizers without the heavy costs associated with dynamic classification or any downsides on pulverizer capacities, maintenance, and parasitic power. Instead, operational flexibility and improved emission control options are enhanced.

-

O&M

JEA Increases Power Output Through CFB Improvements

JEA’s Northside Generating Station in Jacksonville, Fla., Units 1 and 2 were built in 1966 and 1972, respectively, although the Unit 2 boiler had not operated since 1983. Both were heavy oil– and natural gas–fired steam units rated at about 300 MW. The utility “repowered” those two units by removing the old boilers and adding new circulating fluidized bed (CFB) boilers (Figure 1) that entered service in 2002. At that time, they were the world’s two largest CFBs, and the plant won POWER’ s Plant of the Year Award.

-

O&M

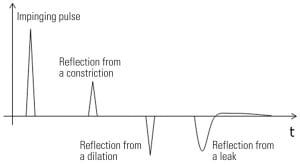

Applying Acoustic Pulse Reflectometry in a Geothermal Plant

Acoustic pulse reflectometry (APR) is a tube inspection method that has been gradually gaining acceptance as a tool for heat exchanger inspection. Different types of heat exchangers operating in different operating environments have different failure mechanisms, making some of them more suited than others for inspection by APR. Finned tube heat exchangers are a typical example of heat exchangers particularly conducive to APR inspection.

-

O&M

Advanced Coatings Protect Plant FGD Systems

Now that many flue gas desulfurization (FGD) systems are reaching middle age, corrosion repairs of structural and process vessels are becoming more common. Corrosion is caused by condensates of acids formed during the FGD process, which accelerate pitting and crevice corrosion, particularly in scrubbers where high sulfate solutions are present. Scrubbers lined with 2205 duplex stainless steel are among the most vulnerable to pit or crevice corrosion, from both chlorides and fluorides.

-

O&M

The New Water Lab

Recent advances in water laboratory instrumentation—from improved sample conditioning to advanced online instruments—have reached the market. Here’s a look at the equipment you’ll find in the best-equipped power plant laboratory this year.