O&M

-

O&M

Major Noise Sources and Mitigation Cost Estimates for Gas-Fired Power Facilities

Natural gas–fired power plants can generate substantial amounts of noise. With proper planning and foresight during the design phase, major noise sources can be effectively mitigated, while failing to plan can be very expensive in the long run.

-

O&M

Upgrading Legacy Gas Turbines’ Fuel Control Systems

Relatively simple upgrades to legacy turbine systems can yield big payoffs in efficiency and reduced maintenance.

-

O&M

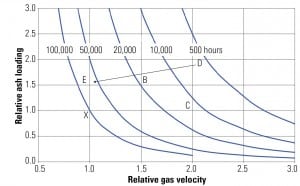

Fly Ash Erosion Control and Prevention

Boiler tube failures (BTFs) are responsible for the largest portion of availability loss (about 4%) in the fossil boiler industry, and approximately 25% of all tube failures are due to fly ash erosion (FAE). An Electric Power Research Institute report indicated that the problem was being managed in U.S. utilities by maintenance activities that were put into effect each time a boiler was taken off-line. The cost of an individual repair was a small fraction of the forced outage cost, and therefore has been considered justified in the past. However, many forced outages continue to be experienced each year due to FAE, and in many cases, these occur at identical locations, indicating that applied solutions relieve, but do not cure, the problem.

-

O&M

Predictive Maintenance That Works

This is the sixth in a series of predictive maintenance (PdM) articles that began in the April 2011 “Focus on O&M” in which the essentials of PdM were introduced. In this occasional segment, we have explored specific PdM techniques, such as motor-current signature analysis, oil analysis and thermographic analysis and their routine use, and ultrasonic and vibration analysis. In this issue we look at lubricating oil wear-particle analysis.

-

O&M

Reducing Ash Agglomeration in JEA’s CFB Boilers

A chronic operational problem with circulating fluidized bed boilers is ash buildup or agglomeration that turns into slag, which forces frequent shutdowns for cleaning. Solving the problem is tricky, because combustion efficiency relies on good fuel quality, but the best fuel for efficiency may not be the best fuel for minimizing furnace and tube fouling and ash plugging.

-

O&M

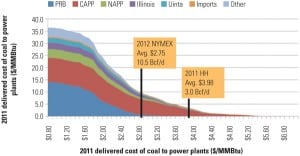

Unit Cycling Makes the Impossible the Ordinary, EUCG Members Say

Low natural gas prices and still-soft electricity demand are forcing low-load and cycling operations at traditionally baseloaded coal units across the country. The resulting challenges were top of mind at the Electric Utility Cost Group’s (EUCG’s) fall meeting in Denver last week. One member of the EUCG’s fossil generation committee from an Ohio Valley utility said that cycling and low-load operations pose challenges for one of his company’s 1,300-MW coal-fired plants that “two years ago we wouldn’t have considered possible.â€

-

O&M

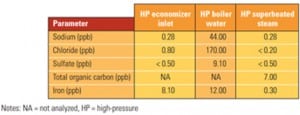

Cycle Chemistry Commissioning Deserves Its Own Strategy

After years of development, design, and construction, your plant is finally nearly ready for startup. But don’t light that cigar yet—at least not until you’ve developed a strategy for commissioning your water cycle chemistry. Root causes of corrosion can be predicted and avoided. The best way to avoid corrosion is to develop and implement plant-specific cycle chemistry commissioning guidelines.

-

O&M

Give Your Plant a Dust Control Tune-Up

Because Powder River Basin (PRB) coal is smaller, more friable, and contains more fine particulates than bituminous coal, controlling the fugitive dust generated as PRB coal moves from bunker to burner tip is problematic. The challenge for material-handling systems at power plants that have switched coals is to minimize this dust and capture it cost-effectively and without compromising safety.

-

O&M

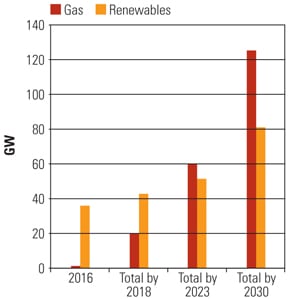

Partners in Reliability: Gas and Electricity

The natural gas and electricity industries have entered into an increasingly codependent relationship as coal-fired electricity gives way to natural gas–fired generation. Both industries are firmly committed to providing reliable service, although each goes about its business in different ways. Utilities, regulators, and stakeholders are searching for ways to align interests and expectations.

-

O&M

O&M and Human Stresses Caused by Low Gas Prices

Plentiful supplies of low-cost natural gas have changed unit dispatch orders across the U.S., led to thermal stress–induced maintenance issues at cycling coal plants, and resulted in management challenges at coal and gas units alike. This scenario is unlikely to change so long as gas holds its competitive edge over coal.