Instrumentation & Controls

-

O&M

Focus on O&M (November 2007)

The NERC auditors are coming / Winning encore for on-line pH monitoring / Using baloons as temporary barriers / How data logging can cut power bills

-

O&M

Plantwide data networks leverage digital technology to the max

To make the most of their digital devices and enable the sharing of data by different departments, new and old plants alike need a reliable digital data infrastructure.

-

Nuclear

Defined scope, experienced team essential to nuclear I&C upgrade projects

Over the past few years, U.S. nuclear power plants have begun replacing their obsolete analog control systems with digital control systems. Many of these projects have been completed successfully, yielding a tidy return on investment in the form of increased generation. However, some have encountered difficulties, which resulted in cost overruns and schedule delays. This minority of projects may have eroded the industry’s confidence in digital upgrade projects, but a well-run project is still one of your best options for squeezing the last drop of performance out of your plant.

-

Nuclear

Accurately measure the dynamic response of pressure instruments

How do you know if a pressure transmitter is giving poor results? Unless the transmitter actually fails, most operators won’t notice a very slow loss in accuracy or response time. Fortunately, the noise analysis technique can identify such changes before they cause a problem. The technique has been used to effectively measure the dynamic response of nuclear power plant pressure sensors and their associated sensing lines. It also can be applied to any plant that relies on accurate instrumentation for control and monitoring plant performance.

-

Coal

Managing air to improve combustion efficiency

The average pulverized coal–fired coal plant is more than 30 years old and has a heat rate in the neighborhood of 10,300 Btu/kWh operating with an "off-design" coal. Add a high load factor (or increased cycling service), squeezed maintenance budgets, reduced plant staff, and increased time between overhauls to meet the plant’s pro forma, and you’ve got major stress. Fortunately, there is a way to come in under your NOx budget and lower the stress. Breathe deeply and read carefully.

-

Coal

Harness detonation waves to clean boiler tubes

Air and steam sootblowers have been the power industry’s solution to the slagging and fouling of boiler convective passes caused by flyash and combustion products. Manual cleaning systems have been superseded by computers and neural nets, but the basic cleaning apparatus remained unchanged—until now. Say hello to detonation waves. They can knock those deposits loose while markedly improving boiler heat transfer efficiency.

-

Instrumentation & Controls

Making the grade with stainless steel tubing

Tubing manufacturers have many alternatives for manufacturing and testing stainless steel tubing for feedwater heater and condenser applications. ASTM specifications are fairly generic in nature and only specify the minimum tube design and testing requirements—which may not be sufficient to provide the appropriate quality for a critical power plant application. To make the right material selections, it’s helpful to understand how welded stainless steel tubing is manufactured and its quality is checked.

-

Instrumentation & Controls

Integrated software platform eludes many owner/operators

Ongoing research into experience with plant- and fleet-level software reveals that these applications work side by side but do not necessarily function as an integrated “knowledge management” system. On the supplier side, the industry continues to be fragmented, with individual programs governing a narrow part of the overall plant.

-

Gas

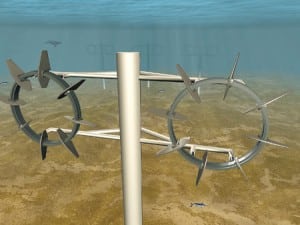

Global Monitor (August 2007)

PG&E mounts tidal power project / GE F-class turbine breaks record / Iowa welcomes ethanol-fed hog / NYPA upgrades pumped-storage plant / Bush blesses Browns Ferry 1 restart / Shearon Harris looks to live on / Nevada bets on solar thermal / Climate models questioned / POWER digest

-

O&M

Finding and fixing leakage within combined HP-IP steam turbines: Part II

By design, combined HP-IP turbines have a small amount of internal leakage from the high-pressure turbine to the intermediate-pressure turbine. As turbines age, the leakage increases considerably and becomes excessive, creating a heat rate penalty and possibly a reliability problem. Last month we explored the symptoms and causes of steam leakage within GE steam turbines and how to correct the problem. In Part II, we examine the same issues for Westinghouse and Allis-Chalmers turbines from both theoretical and practical angles.