Gas

-

Gas

Flexible Turbine Operation Is Vital for a Robust Grid

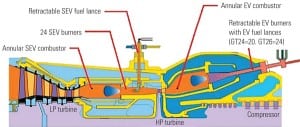

Renewable electricity generation has many environmental advantages, but adding large amounts of far-flung renewable resources to a grid requires increased operating flexibility from dispatchable generators when the wind doesn’t blow or the sun doesn’t shine. One promising option: A combined-cycle plant based on Alstom’s GT24/GT26 combustion turbine can be “parked” at approximately 20% plant load while producing emissions comparable to those during baseload operation—with little loss in thermal efficiency. When demand returns, the combined cycle can return to baseload within minutes.

-

Gas

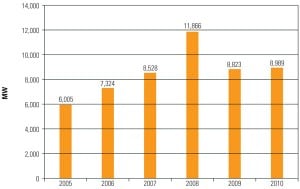

U.S. Gas-Fired Power Development: Last Man Standing

In 2010, U.S. wind power development has slowed, coal-fired power development remained stalled, and the much-awaited renaissance of nuclear power took a few tentative steps forward. That left natural gas power development as the last man standing.

-

Gas

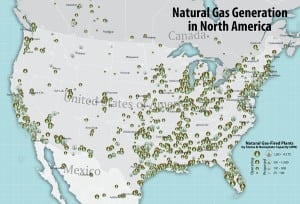

Industry Trends: Map of Natural Gas Generation in North America

Courtesy: Platts Data source: POWERmap All rights reserved. No reproduction allowed.

-

Gas

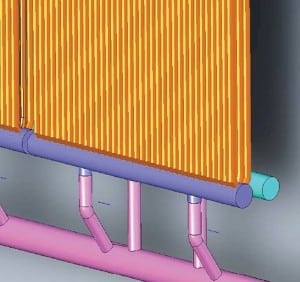

The World’s First Two-Stage Turbocharged Gas Engine

GE launched what it is calling the world’s first two-stage turbocharged gas engine this June.

-

O&M

Ten Years of Experience with FAC in HRSGs

We first reported on combined-cycle plant reliability concerns due to erosive wear and flow accelerated corrosion (FAC) in heat-recovery steam generator (HRSG) pressure parts at the 1999 EPRI Maintenance Conference. More than 10 years later, these damage mechanisms remain significant contributors to forced outages, pressure part repairs, and major component replacement.

-

Gas

Top Plant: Langage Combined Cycle Power Plant, Plymouth, Devon, UK

The UK grid, focused on adding valuable renewable generation, will rely on natural gas–fired generation for many years to come. One of the most recent additions is the Langage Power Plant, designed for quick response and low load “parking” at night while remaining below air emissions limits. With an extraordinary architectural design that blends into the natural surroundings, Langage is now a local landmark.

-

Gas

Top Plant: Panoche Energy Center, Firebaugh, California

The Panoche Energy Center is a 400-MW simple-cycle power plant using four of General Electric’s GE LMS100s with fast-start capability. Dispatched by Pacific Gas & Electric to meet regional power and grid stabilization needs, the project entered commercial service two months earlier than planned. Panoche is the largest LMS100 peaking facility in the U.S.

-

Gas

Top Plant: Ras Laffan Power and Water Plant, Ras Laffan Industrial City, Qatar

At the Ras Laffan Power Co. facility, the 756-MW net combined-cycle plant and the integrated 40 million gallons per day desalination plant are working in tandem to provide abundant, reliable electricity and desalinated water to residents of the State of Qatar, the most prosperous nation in the Middle East.

-

Gas

Top Plant: Sloe Centrale Power Plant, Vlissingen-Oost, Zeeland Province, Netherlands

There’s nothing slow about the fast-track operations at the new 870-MW Sloe Centrale Power Plant. The combined-cycle plant is designed for 250 starts per year and is capable of supplying power to the grid within a mere 30 to 40 minutes. In addition to its impressive rapid load response, the gas-fired plant produces low CO2 and NOx emissions by using the latest technology. It also attains an efficiency of 59%.

-

Gas

Top Plant: Timelkam Power Plant Vöcklabruck District, Upper Austria, Austria

Now that the 412-MW Timelkam Power Plant has replaced a 47-year-old coal-fired power plant located in the Vöcklabruck District, northern Austrians can bid auf wiedersehen (goodbye) to high levels of air pollution. Compared to its predecessor, the new gas-fired combined-cycle plant has dramatically cut CO2 and NOx emissions and produces seven times more energy.

-

Gas

Top Plant: West County Energy Center, Palm Beach County, Florida

The 3,600-MW West County Energy Center, with two recently commissioned power blocks and a third just entering start-up, is the first “greenfield” combined-cycle plant constructed by FPL since the 1970s. Thanks to FPL’s long history with repowering projects, the project team commissioned Unit 2 seven months early, with no operator errors during start-up. At just over $600/kW, the cost of the plant was a bargain.

-

Gas

High-Efficiency Gas Turbines Go to Market

This May, following two years of construction, Siemens Energy put into operation Irsching 5, an 847-MW advanced combined-cycle power plant near Ingolstadt, Germany. The plant’s owner, Gemeinschaftskraftwerke Irsching GmbH—a joint venture of E.ON, Mainova, and HEAG Südhessische Energie—features two SGT5-4000F gas turbines, one SST5-5000 steam turbine, three hydrogen-cooled generators, electrical systems, and Siemens’ SPPA-T3000 instrumentation and control system.

-

Coal

Breathing Added Life into Failing Heat Exchangers

When heat exchanger tubes—sometimes numbering a thousand or more per unit—begin to crack or wear, the effects can lead to a cascade of subsequent failures in adjacent tubes. If too many tubes are plugged, heat exchanger effectiveness is compromised, and power generation may be curtailed. If conventional mechanical plugs are used, they can break loose, leak, and fail. At that point, the replacement of a very costly heat exchanger is imminent.

-

Gas

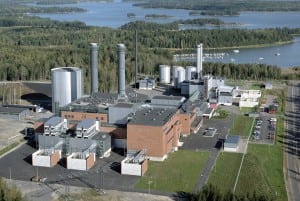

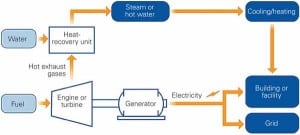

Local Warming: Helsingin Energia Uses CHP to Heat a City

Power plant operators, especially those located in countries with enforceable carbon emissions standards, are concerned about their CO2 emissions. But for Helsingin Energia—which provides power, heating, and cooling for Helsinki, Finland’s 300,000 residents—the main concern is local warming, not global warming. In Helsinki, temperatures on midsummer afternoons only reach an average 21C, and for half the year daytime temperatures are below 10C.

-

Coal

Protect Your Stack Linings from Corrosion

Stacks at power generating stations may be low maintenance, but they are not no maintenance. The cost of preventing corrosion may be as little as $10,000, but the cost of repair or replacement could be many times that or even put your plant out of commission until the stack problem is corrected.

-

Coal

Luminant’s Oak Grove Power Plant Earns POWER’s Highest Honor

Luminant used remnants of the ill-fated Twin Oaks and Forest Grove plants (which were mothballed more than 30 years ago) to build the new two-unit 1,600-MW Oak Grove Plant. Though outfitted with equipment from those old plants, Oak Grove also sports an array of modern air quality control equipment and is the nation’s first 100% lignite-fired plant to adopt selective catalytic reduction for NOx control and activated carbon sorbent injection technology to remove mercury. For melding two different steam generators into a single project, adopting a unique and efficient “push-pull” fuel delivery system, assembling a tightly integrated team that completed the project on time and within budget, and for completing what was started almost four decades ago, Oak Grove Power Plant is awarded POWER magazine’s 2010 Plant of the Year award.

-

Coal

Lean Construction Principles Eliminate Waste

Eliminate waste in coal, gas, or nuclear power plant construction through a holistic application of lean principles.

-

History

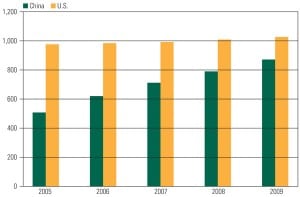

China: A World Powerhouse

It’s no surprise that China leads the world in recent power capacity additions. What may surprise you is the precise mix of options this vast country is relying upon to meet its ever-growing demand for electricity. As a result, this ancient civilization is fast becoming the test bed and factory for the newest generation and transmission technologies.

-

Coal

Industry Pivots on Natural Gas, Hails Cap and Trade

At the opening ELECTRIC POWER 2010 plenary session, both the keynote speaker’s address and discussion among the Power Industry Executive Roundtable participants pointed to the renewed appeal of natural gas and proposed cap-and-trade legislation as being potential game-changers for the U.S. power industry.

-

Gas

Qatar Opens 2,000-MW Gas Plant

The gas-rich emirate of Qatar, holder the world’s third-largest gas reserves, inaugurated another massive 2,000-MW gas power plant in the industrial city of Mesaieed, south of the capital Doha this May.

-

Gas

Qatar Opens 2,000-MW Gas Plant

The gas-rich emirate of Qatar, holder the world’s third-largest gas reserves, inaugurated another massive 2,000-MW gas power plant in the industrial city of Mesaieed, south of the capital Doha this May.

-

Gas

DOE Expedition Confirms Resource- Quality Gas Hydrate in the Gulf of Mexico

Gas hydrate, a potentially immense energy resource, occurs at high saturations within reservoir-quality sands in the Gulf of Mexico, an expedition by the U.S. Department of Energy has discovered.

-

Gas

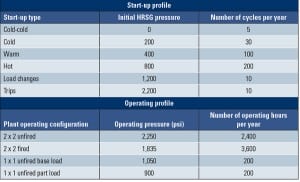

Economic Operation of Fast-Starting HRSGs

Fast-starting combined-cycle plants are designed for a certain operating life based on a customer-specified set of operating scenarios. During that design phase, periodic inspection and maintenance procedures to benchmark equipment actual wear and tear should be developed, but seldom are. Without an accurate assessment of remaining equipment life for components subjected to fast and frequent […]

-

Gas

Kawasaki Plant Claims Efficiency Record

Tokyo Electric Power Co.’s new Kawasaki Thermal Power Plant claims the title of having the highest combined-cycle efficiency in the world: 59.1%. The new gas-fired facility is equipped with three 500-MW single-shaft combined-cycle blocks. Each block is based on the MHI M701G2 gas turbine, which is the largest gas turbine currently in commercial operation.

-

O&M

Improving SCR Performance on Simple-Cycle Combustion Turbines

Austin Energy replaced the selective catalytic reduction (SCR) catalyst twice over five years for its four peaker turbines. The duct modifications and injection grid redesign, combined with new catalyst, are producing high NOx reduction and low ammonia slip, and the catalyst is now expected to last at least five years.

-

O&M

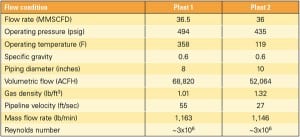

Real-Time Monitoring of Natural Gas Fuel Cleanliness

Gas turbines require clean gas to operate efficiently. Particulate contamination fouls fuel nozzles, causes increases in flue stack emissions, and occasionally causes unplanned plant outages. Now a new real-time natural gas cleanliness monitoring and web-based alarm system is providing valuable protection for natural gas–fired power plants. The adaptation of laser light–scattering technology for the purpose of contaminant measurement in high-pressure gaseous pipelines provides a method of monitoring liquid and solid contamination levels.

-

O&M

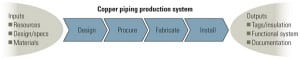

Natural Gas Piping: It’s Time for Better Risk Control

At least 10 workers have died from natural gas piping explosions in the past 12 months. The most recent disaster, which occurred during gas system purging at the Kleen Energy Systems plant, claimed five lives and injured 27 workers. It’s time the industry understood the unique design and safety requirements for working with and purging natural gas piping.

-

Coal

Adding Desalination to Solar Hybrid and Fossil Plants

Shrinking water supplies will unquestionably constrain the development of future power plants. A hybrid system consisting of concentrated solar thermal power and desalination to produce water for a plant, integrated with a combined cycle or conventional steam plant, may be the simple solution.

-

Gas

Brazil Beings Operation of Ethanol Power Plant

Brazil’s state-owned oil producer, Petrobras, on Dec. 31, 2009, said it had inaugurated the world’s first power plant to run exclusively on ethanol.

-

Coal

Plant Efficiency: Begin with the Right Definitions

The race is on to claim the title of "most efficient coal-fired power plant" on the planet. However, it’s tricky identifying finalists because of the widespread misuse of the term "efficiency" and all those nagging assumptions. Let’s first establish clear definitions and then identify the title contenders.